Enhanced TDS

Identification & Functionality

- Blend

- No

- CAS Number

- 28064-14-4

- CASE Ingredients Functions

- Chemical Family

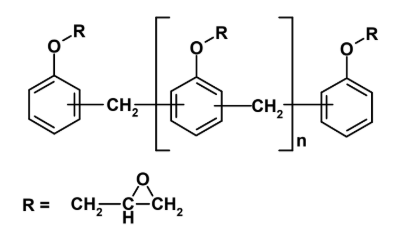

- Chemical Name

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials,Binder & Resin

- Single Ingredient

- Yes

- Synonyms

- Phenol-Formaldehyde Polymer Glycidyl Ether, Phenol-Formaldehyde Polymer Oxiranylmethyl Ether

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Composites End Use

- Cure Method

- Markets

- Applications

- Application Details

- Good solvent resistance

- Good chemical resistance

- Good heat resistance

- Compliant with FDA listings in 21CFR 175.300

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

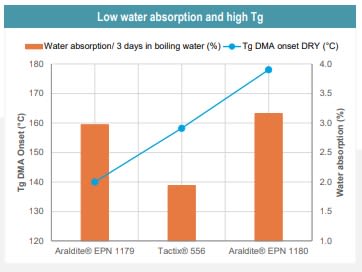

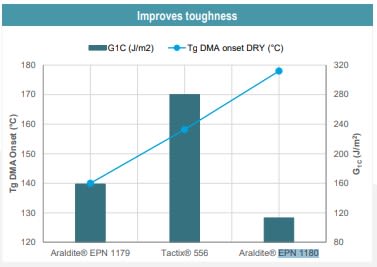

- Technical Graphs

We recommend our DCPD epoxy resin to deliver the best water, chemical and temperature resistance performance

Stoichiometric cure with OMICURE® DDA10 / OMICURE® U24 (100/46 pbw) Cure profile: 2h at 100°C + 2h at 150°C + 2h at 220°C - Tg measured via DMA (G’ Onset)

Packaging & Availability

- Regional Availability

- Packaging Information

ARALDITE® EPN 1179 and ARALDITE® EPN 1180 are supplied in 484 pounds steel drums

Storage & Handling

- Storage Information

These products should be stored in a dry place, in the sealed original container, at temperatures between +2°C and +40°C (+35.6°F and 104°F). Under these storage conditions the shelf life is 3 years. These products should not be exposed to direct sunlight.

Other

- Appearance (SDS)

- Paste

- Color (SDS)

- Light yellow

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Functionality 3.6 - - Physical Properties

Value Units Test Method / Conditions Density 1.22 g/cm³ g/cm³ At 25°C Flash Point min. 200.0 °C °C Viscosity 20000.0-50000.0 mPa.s mPa.s at 52°C Viscosity 5000.0 mPa.s mPa.s At 65°C