Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder & Resin

- Single Ingredient

- Yes

- Technologies

- Product Families

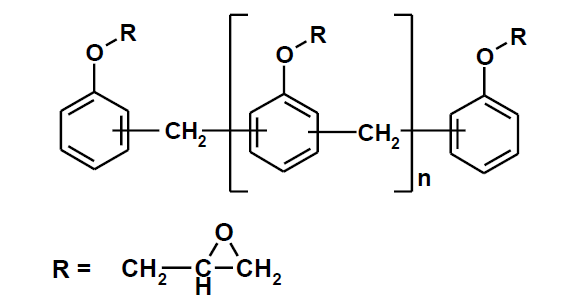

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Advantages

- Excellent solvent resistance

- Outstanding chemical resistance

- Exceptional heat resistance

- Product Features

- ARALDITE® EPN 1180 MBC contain more than two epoxy groups per molecule and can be described as multifunctional epoxy resins. Due to the increased epoxy functionality, EPN resins provide a high cross-link density when properly cured.

- Systems based on ARALDITE® EPN 1180 MBC possess better chemical and high temperature resistance than those based on standard bisphenol A epoxy resins.

- EPN resins are recommended for high performance applications requiring excellent chemical and solvent resistance.

- When combined with suitable curing agents (i.e. polyamines, novolacs and anhydrides), they can be used as the sole resins, or in blends with bisphenol A and F epoxy resins, to upgrade the performance of the latter.

- EPN resins can be used in two-component room temperature cure, forced cure or heat cure systems.

- Solvent-containing, high solids, solvent-free or waterborne coatings can be formulated.

- The heat-curable systems produce the ultimate performance (chemical and thermal resistance).

- This is due to more complete reactions with the curing agents at higher temperatures, and overcoming the steric hindrance of the multifunctional epoxy resins.

Applications & Uses

- Coating End Applications

- Cure Method

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ARALDITE® EPN 1180 MBC should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40°C.

- The product should not be stored exposed to direct sunlight.

- Handling Information

Mandatory and recommended industrial hygiene procedures should be followed whenever our products are being handled and processed.

Other

- Appearance

- Clear viscous liquid

- Color (SDS)

- Light Yellow

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 175.0-182.0 g/eq g/eq ISO 3001 - Physical Properties

Value Units Test Method / Conditions Flash Point min. 200.0 °C °C ISO 2592 Viscosity 20000.0-50000.0 mPa.s mPa.s Falling Ball Viscometer at 52°C Viscosity 20000.0-50000.0 mPa.s mPa.s ISO 12058-1 at 52°C