Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Processing

Casting / Impregnating

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

Encapsulating, potting and/or impregnating of low voltage and electronic components

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Properties

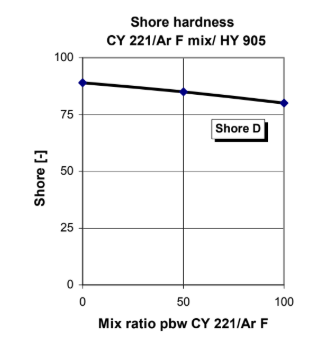

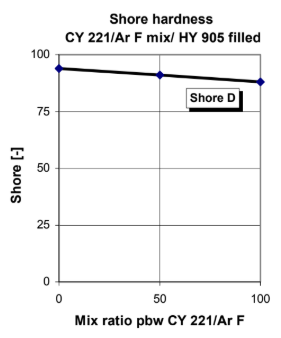

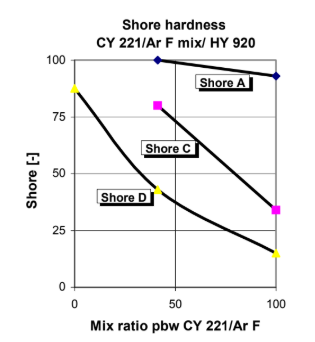

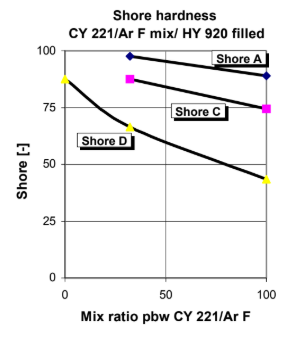

The flexibility of castings can be adapted to requirements by combining Araldit F and CY 221

Low tendency to cracking

Castings possess high or low flexibility as desired and have little tendency to cracking

Good resistance to thermal ageing- Cured Properties

Key Value Unit Test Method Test Condition Bending Test Strength (max.) 130 MPa ISO 178 Bending Test Strength (breaking) 110 MPa ISO 178 Surface Strain (F max.) 6 % ISO 178 Surface Strain (F breaking) 10 % ISO 178 Impact Bending Test 20 kJ/m² ISO 179 Tensile Test Strength (max.) at 23°C 70 MPa ISO/R 527 at 23°C Tensile Test Strength (breaking) at 23°C 70 MPa ISO/R 527 at 23°C Tensile Test Extension (F max.) at 23°C 2.5 % ISO/R 527 at 23°C Tensile Test Extension (F breaking) at 23°C - % ISO/R 527 at 23°C Tensile Test Strength (max.) at 0°C - MPa ISO/R 527 at 0°C Tensile Test Strength (breaking) at 0°C - MPa ISO/R 527 at 0°C Tensile Test Extension (F max.) at 0°C - % ISO/R 527 at 0°C Tensile Test Extension (F breaking) at 0°C - % ISO/R 527 at 0°C Tensile Test Strength (max.) at -20°C - MPa ISO/R 527 at -20°C Tensile Test Strength (breaking) at -20°C - MPa ISO/R 527 at -20°C Tensile Test Extension (F max.) at -20°C - % ISO/R 527 at -20°C Tensile Test Extension (F breaking) at -20°C - % ISO/R 527 at -20°C Martens Dimensional Stability under Heat 90 °C DIN 53 458 Electric Strength (2mm plate, 50 Hz) 20 kV/mm IEC 243 2 mm plate Electric Strength Instantaneous Value 20 kV/mm IEC 243 50 Hz, Instantaneous

Electric Strength 1-min value 17 kV/mm IEC 243 50 Hz, 1-min value

Arc Resistance 85 s ASTM D 495 Tracking Resistance (Test Solution A) >600 CTI IEC 112 Electrolytic Corrosion A1 grade IEC 60426

Safety & Health

- Handling Precautions

Safety precautions at workplace:

protective clothing : yes

gloves : essential

arm protectors : recommended when skin contact likely

goggles/safety glasses : yes

respirator/dust mask : recommended

Skin protection

before starting work : Apply barrier cream to exposed skin

after washing : Apply barrier or nourishing cream

Cleansing of contaminated skin : Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Clean shop requirements : Cover workbenches, etc. with light coloured paper. Use disposable beakers, etc.

Disposal of spillage : Soak up with sawdust or cotton waste and

Ventilation:

of workshop : deposit in plastic-lined bin

of workplace : Renew air 3 to 5 times an hour Exhaust fans. Operatives should avoid inhaling vapours.- Industrial Hygiene

Mandatory and recommended industrial hygiene procedures should be followed when-ever our products are being handled and processed. For additional information please consult the corresponding Safety Data Sheets and the brochure “Hygienic precautions for handling plastics products”.

- First Aid

Contamination of the eyes by resin, Aradur or casting mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately. Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

Storage & Handling

- Storage Conditions

Store the components in a dry place at 18-25°C, in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use. For information on waste disposal and hazardous products of decomposition in the event of a fire, refer to the Material Safety Data Sheets (MSDS) for these particular products.