Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Properties

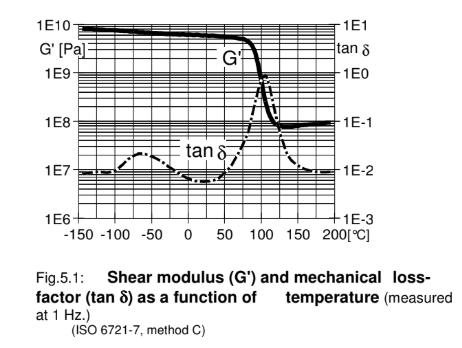

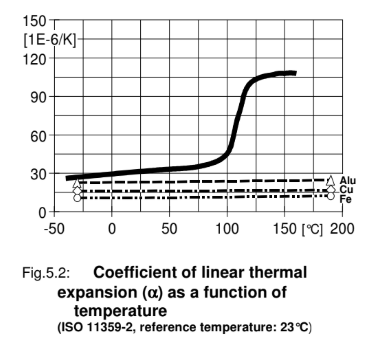

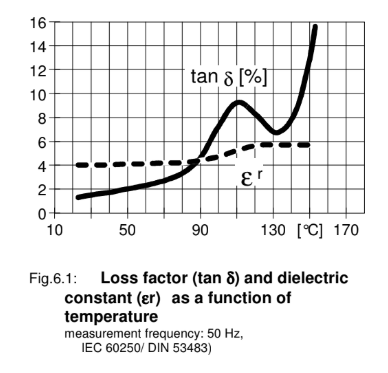

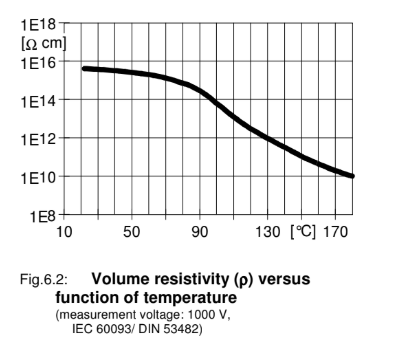

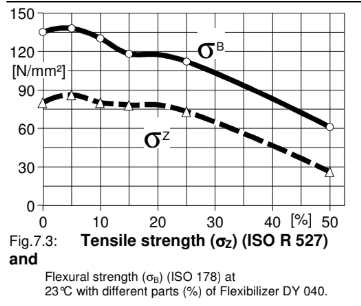

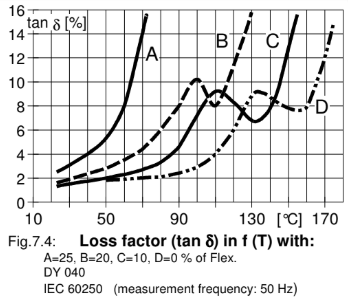

- Good mechanical and electrical end properties

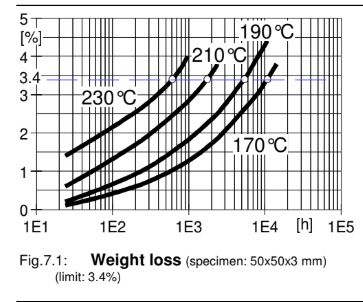

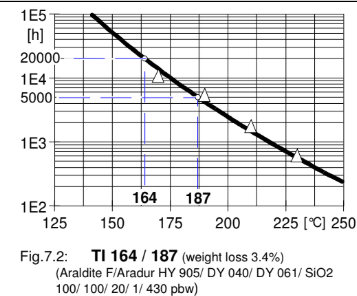

- Very high thermal endurance properties

- Considerable insensitivity to atmospheric and chemical influences.

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Application Information

Indoor electrical insulators for medium and high voltage, such as post insulators, bushings, switch and apparatus components as well as instrument transformers and dry type distribution transformers.

- Processing Methods

- Conventional gravity casting process under vacuum.

- Adjustable to existing handling parameters.

Properties

- Physical Form

Technical Details & Test Data

- Cured Properties

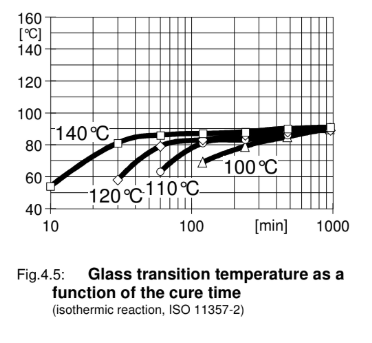

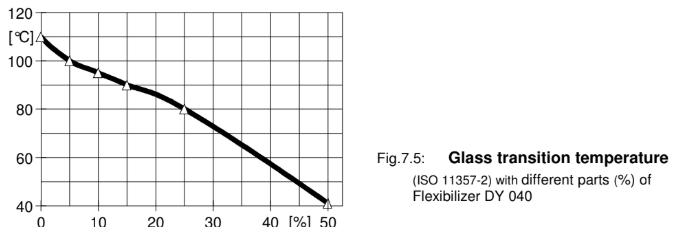

Key Value Unit Test Method Test Condition Glass Transition Temperature 95 - 100 °C ISO 11357-2 4h 80°C + 4h 120°C

Tensile Strength 88 - 91 MPa ISO 527 Cure: 4h 80°C + 4h 120°C

Elongation at Tensile Strength 5.0 - 6.0 % ISO 527 Cure: 4h 80°C + 4h 120°C

Ultimate Strength 87 - 94 MPa ISO 527 Cure: 4h 80°C + 4h 120°C

Ultimate Elongation 5.5 - 6.5 % ISO 527 Cure: 4h 80°C + 4h 120°C

Flexural Strength 150 - 155 MPa ISO 178 Cure: 4h 80°C + 4h 120°C

Elongation at Flexural Strength 6.5 - 7.0 % ISO 178 Cure: 4h 80°C + 4h 120°C

Ultimate Strength (Flexural) 148 - 155 MPa ISO 178 Cure: 4h 80°C + 4h 120°C

Ultimate Elongation (Flexural) 6.5 - 8 % ISO 178 Cure: 4h 80°C + 4h 120°C

Flexural Modulus 3050 - 3350 MPa ISO 178 Cure: 4h 80°C + 4h 120°C

Fracture Toughness K1C 0.57 - 0.60 MPa·m½ ISO 13586 Cure: 4h 80°C + 4h 120°C

Fracture Energy G1C 110 - 120 J/m² ISO 13586 Cure: 4h 80°C + 4h 120°C

Water Absorption (1 day) 0.10 - 0.15 % by wt. ISO 62 Cure: 4h 80°C + 4h 120°C

Water Absorption (10 days) 0.35 - 0.40 % by wt. ISO 62 Cure: 4h 80°C + 4h 120°C

Breakdown Strength 18 - 22 kV/mm IEC 60243-1 3 mm specimen Breakdown Strength (Rogowski Electrodes) 36 - 41 kV/mm Huntsman Method Ø = 25mm, 2 mm gap

Diffusion Breakdown Strength HD 2 class DIN/VDE 0441/1 Temperature after test

HV Arc Resistance 185 - 195 s IEC 61621 3 mm specimen Tracking Resistance (Test Solution A) >600 CTI IEC 60112 10mm specimen Tracking Resistance (Test Solution B) >600M-0.0 CTI IEC 60112 10mm specimen Electrolytic Corrosion A-1 grade IEC 60426 Dielectric Strength >29 kV/mm IEC 60243-1 3 mm specimen Dielectric Loss Factor 0.2 % IEC 60250 25°C, 50Hz Dielectric Constant (εr) 3.4 - IEC 60250 25°C, 50Hz Volume Resistivity 2.5 x 10¹⁶ Ω cm IEC 60093 25°C

Storage & Handling

- Storage Conditions

Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use.

For information on waste disposal and hazardous products of decomposition in the event of a fire, refer to the Material Safety Data Sheets (MSDS) for these particular products.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.002-0.01 %(W) %(W) Accelerator : Resin Mix Ratio 3.1-4.3 %(W) %(W) Filler : Resin Mix Ratio 0.0-0.2 %(W) %(W) Flexibilizer : Resin Mix Ratio 1.0 %(W) %(W) Hardener : Resin