Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Properties

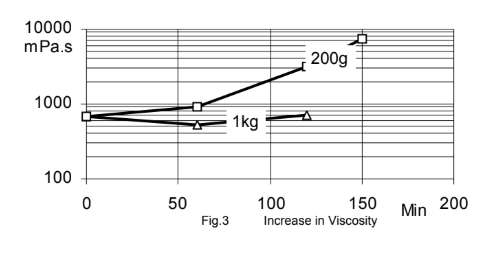

- Solvent free, low viscosity, hot curing prepreg system with long open time.

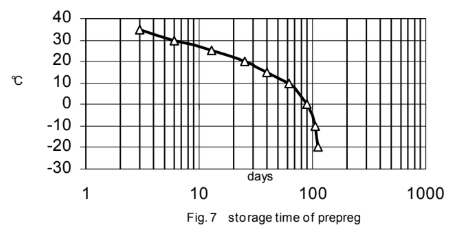

- Excellent adhesive and laminating properties. Before processing the laminate, storage times depending on various parameters are necessary. Usually an immediate processing of the impregnated material should not be done.

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Application Information

Prepreg system for the ski industry.

Properties

- Physical Form

Technical Details & Test Data

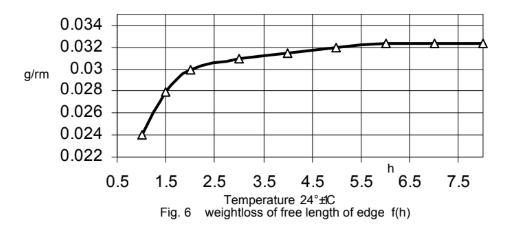

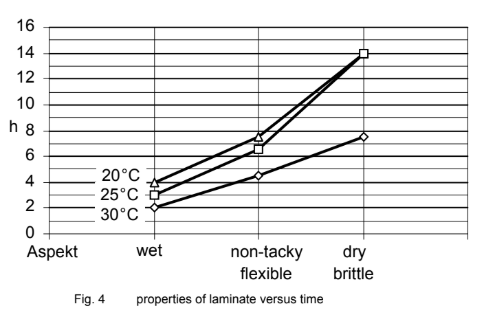

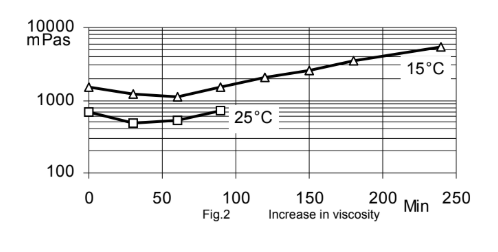

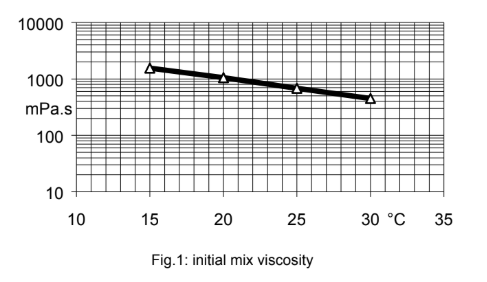

- Graphs

- Cured Properties

Key Value Unit Test Method Test Condition Glass Transition Temperature 95 - 100 °C IEC 1006 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Tensile Strength 88 - 95 MPa ISO 527 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Elongation at Tensile Strength 5 - 6 % ISO 527 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Ultimate Strength 87 - 94 MPa ISO 527 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Ultimate Elongation 5.5 - 6.5 % ISO 527 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Tensile Modulus 3100 - 3300 MPa ISO 527 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Flexural Strength 150 - 155 MPa ISO 178 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Elongation at Flexural Strength 6.5 - 7.0 % ISO 178 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Ultimate Strength 148 - 155 MPa ISO 178 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Ultimate Elongation 6.5 - 8.0 % ISO 178 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Flexural Modulus 3050 - 3200 MPa ISO 178 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Fracture Toughness (K1C) 0.57 - 0.60 MPa·m¹/² ISO 13586 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Fracture Energy (G1C) 110 - 120 J/m² ISO 13586 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Water Absorption (1 day) 0.10 - 0.15 % ISO 62 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Water Absorption (10 days) 0.35 - 0.40 % ISO 62 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Poisson’s Ratio 0.35 Cured for 4 hours at 80°C and post-cured for 4 hours at 140°C

Shear Strength (Shear Test) 15.6 N/mm² DIN 53.283 ALU/ALU Cured at 100°C/15 min, 40°C/92% Humid. Acc.

Peel Test (Peel Strength) 1 N/mm DIN 53.289 ALU/LAM Cured at 100°C/15 min, 40°C/92% Humid. Acc.

Drum Peel Test (ALU/LAM) 1.5 - 1.6 N/mm DIN 53.295 Cured at 100°C/15 min, 6-8 bar pressure

Safety & Health

- First Aid

Contamination of the eyes by resin, hardener or mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately. Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

- Handling Precautions

Personal hygiene

Safety precautions at workplace

protective clothing : yes

gloves : essential

arm protectors : recommended when skin contact likely

goggles/safety glasses : yes

Skin protection

before starting work : Apply barrier cream to exposed skin

after washing : Apply barrier or nourishing cream

Cleansing of contaminated skin

Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Disposal of spillage : Soak up with sawdust or cotton waste and deposit in plastic-lined bin

Ventilation

of workshop : Renew air 3 to 5 times an hour

of workplaces : Exhaust fans. Operatives should avoid inhaling vapours

Storage & Handling

- Storage Conditions

Provided that the products described above are stored in a dry place in their original, properly closed containers at a temperature of 18-25°C they will have the shelf lives indicated on the labels. Partly emptied containers should be closed immediately after use. For hazardous decomposition products when disposed of in fire and disposal guidelines see MSDS