Enhanced TDS

Identification & Functionality

- RTU Product Type

- Technologies

- Product Families

- Chemical Description

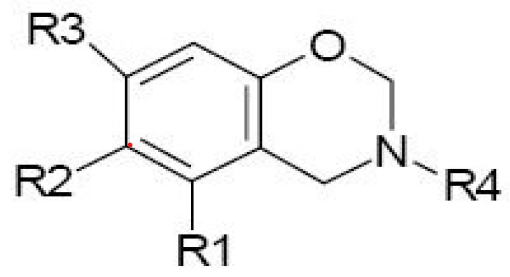

Araldite LZ 8278 N70 Resin is benzoxazine resin based solution with 70% by weight solids in methyl ethyl ketone. The base benzoxazine resin is chemically characterized by the general benzoxazine structure shown below:

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

Laminates and prepregs for printed wiring boards for

- Low moisture absorption

- Good thermal stability

- High modulus

- Compatible with lead-free processes

- Good moisture resistance

- High modulus

- Good thermal performance, T288 > 60min

- Low Z axis expansion

- UL 94 V0

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

Laminates and prepregs for printed wiring boards with the following performance:

- Non-halogen FR-4

- High reliability applications

- High Density Interconnect (HDI) PCBs

Properties

- Flame Rating

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Curing Cycle

Parameter #1 Initial temperature 80 °C Heating Ramp 2 - 3 °C /min Final Temperature 210 °C Pressure ≥ 350 psi Time at Final Temperature 85 - 95 min - Typical Properties

Varnish Formulation 1 Araldite LZ 8278 N70 Resin 100 g Aradur HZ 8279 Z40 Resin 37.5 g Mg(OH)2 13 g 2-MI 0.1 g Solvent 45 g SiOz 26 g Varnish gel timeat 171°C 230 s Preperg process parameter Oven temperature 171°C Baking time 190 - 220 s Preperg gel timeat 171 °C 110 - 140 s Laminating Cycle parameter Curing temperature 210°C Curing time 90 min RC 40 - 45 % Laminate properties Tg (DSC 10°C/min) 208 / 209°C Tg. (DMA 5°C/min Onset) 206°C Peel strength (1oz ED copper) 1.2 N/mm CTE [Below Tg] 30-50 ppm/°C Td (5% weight lose) > 380°C T288 > 60 min T288 clad 12 min UL-94 VO PCT Water Absorption (120°C&300min)| 0.30% Solder dip (after 120°C&300min PCT) > 5 min - Product Properties

- Good moisture resistance

- High modulus

- Good thermal performance, T288 > 60min

- Low Z axis expansion

- UL 94 V0

- Glass Fabric Pretreatment

The epoxy silane is recommended to pretreatment of the glass fabric.

- Varnish Preparation

Araldite LZ 8278 N70 Resin / Aradur HZ 8279 Z40 Resin non-halogen benzoxazine resin system can be formulated with common solvent such as PM, PMA, and Cyclohexanone which is Typically used to manufacture prepregs for PWB applications.

Component Formulation #1 Araldite LZ 8278 N70 Resin 100 g Aradur HZ 8279 Z40 Resin 37.5 g Mg(OH)2 /Fused SiO2 25 - 55g 2 MI 0.05 - 0.1 g solvent 5 - 60 g Solid content 55% - 65% Gel time at 171°C 230 - 330s Remark:The gel time can be adjusted by the ratio of 2 MI

Safety & Health

- Handling Precautions

First Aid

In case of contact:- Skin: Immediately wash with soap and water. Remove contaminated clothing and launder before reuse. Destroy contaminated shoes.

- Eyes: Immediately flush with water for at least 15 minutes. Call a physician.

- Ingestion: If conscious, give plenty of water to drink. Do not induce vomiting. Call a physician.

- Inhalation: Remove to fresh air. Administer oxygen or artificial respiration if necessary. Call a physician.

- Other: Referral to physician is recommended if there is any question about the seriousness of any injury.

Storage & Handling

- Storage Conditions

Araldite LZ8278 N70 and Aradur HZ8279 Z40 may be stored for up to 9 months at +5 ~ +40°C respectively provided the components are stored in sealed containers. The expiry date is indicated on the label.