Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials,Viscosity Modifier

- Polymer Name

- Single Ingredient

- Yes

- Technologies

- Product Families

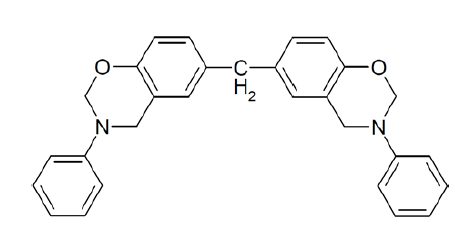

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Features

- Good flammability resistance UL94 V1

- Excellent chemical resistance

- Low water absorption

- Dimensional stability

- High modulus properties

- Can be processed via Pultrusion, Pre-preg, Pressure Molding, and Resin Transfer Molding (RTM)

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Polymers & Resins

- Composites End Use

- Composites Processing Methods

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage and Handling Information

Araldite® MT35700 Benzoxazine Resin should be stored away from excessive heat and humidity in the original sealed container at a temperatures around 77°F. Under these storage conditions the shelf life is 1 years (from date of manufacture). The product should not be exposed to direct sunlight.

Other

- Appearance

- Yellow solid

- Color (SDS)

- Light Yellow

- Odor (SDS)

- Odorless

- Mechanical Properties

Value Units Test Method / Conditions Flexural Strength1 127.0 MPa ISO 178/01 Cured for 2h at 180°C + 2h at 200°C Tensile Strength2 69.0 MPa ISO 527 T2/93 Cured for 2h at 180°C + 2h at 200°C - Physical Properties

Value Units Test Method / Conditions Gel Time 200.0-450.0 s at 220°C Glass Transition Temperature (Tg) 145.0-155.0 °C Differential Scanning Calorimetry ramp at 10°C/30°C-300°C/nitrogen Glass Transition Temperature (Tg)1 160.0-170.0 °C Dynamic Mechanical Analysis (DMA) ramp at 10°C / 30°C - 300°C / nitrogen Melting Point 60.0-80.0 °C Viscosity 2000.0-5500.0 cPs at 100°C