Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Properties

- High mechanical and electrical properties at elevated temperature

- High thermal shock resistance

- Excellent radiation resistance

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Processing Methods

Vacuum Pressure Impregnation (VPI - process)

- Application Information

Large coils for magnets and/or rotating machines

Properties

- Physical Form

- Product Data

Aradur HY 906 Liquid, dicarboxylic Anhydride

Property Key Value Unit Test Method Condition Viscosity 200 - 350 mPa s ISO 12058 at 25°C Density 1.20 - 1.25 g/cm³ ISO 1675 at 20°C Flash point 135 - 167 °C ISO 1523 Vapour pressure < 20 Pa Knudsen at 50°C Araldite MY 740 Liquid, unmodified, solvent-free Bisphenol A epoxy resin

Property Key Value Unit Test Method Condition Viscosity 10000 - 14500 mPa s ISO 12058 at 25°C Epoxy content 5.25 - 5.55 equiv/kg ISO 3001 Density 1.15 - 1.20 g/cm³ ISO 1675 at 25°C Flash point > 200 °C ISO 1523 Vapour pressure < 0.01 Pa Knudsen at 20°C Vapour pressure < 0.5 Pa Knudsen at 60°C Accelerator DY 073-1 Liquid, modified Amine Complex

Property Key Value Unit Test Method Condition Viscosity 5 - 15 mPa s ISO 12058 at 25°C Density 0.95 - 1.00 g/cm³ ISO 1675 at 25°C Flash point 82 °C ISO 1523 Vapour pressure < 6 Pa Knudsen at 20°C "

Technical Details & Test Data

- Mechanical Properties

Curing Cycle: 6h at 100°C + 12h at 135°C

Key Value Unite Test Method Condition Flexural strength 130 - 140 MPa ISO 178 Surface strain 5.1 - 5.7 % ISO 178 Impact strength 14 - 17 kJ/m² ISO 179 Glass Transition Temperature 130 - 140 °C ISO 11357-2 Water Absorption (60 min at 100°C) 0.15 - 0.20 % by wt. ISO 62 at 100°C Water Absorption (600 min at 100°C) 0.55 - 0.65 % by wt. ISO 62 at 100°C Water Absorption (100 h at 100°C) 1.15 - 1.20 % by wt. ISO 62 at 100°C Curing Cycle: 6h at 100°C + 12h at 135°C + 3h at 160°C

Key Value Unite Test Method Condition Flexural strength 125 - 135 MPa ISO 178 Surface strain 4.4 - 5.0 % ISO 178 Impact strength 15 - 18 kJ/m² ISO 179 Glass Transition Temperature 140 - 145 °C ISO 11357-2 Water Absorption (60 min at 100°C) 0.15 - 0.20 % by wt. ISO 62 at 100°C Water Absorption (600 min at 100°C) 0.55 - 0.65 % by wt. ISO 62 at 100°C Water Absorption (100 h at 100°C) 1.0 - 1.1 % by wt. ISO 62 at 100°C Glass Transition Temperature 125 - 130 °C ISO 11357-2 - Viscosity Increase

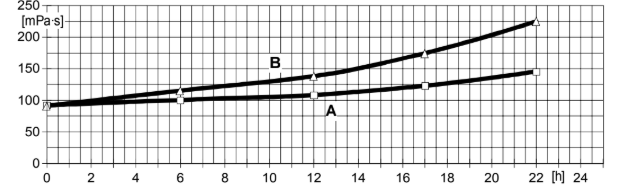

Fig.3.1: Viscosity increase at 60°C as a function of the time (measurements with Rheanat 115A, MSDIN 125/shear rate Dc 10S –1) A = 0.5 pbw Accelerator DY 073-1 / B = 1 pbw Accelerator DY 073-1

- Gel Time

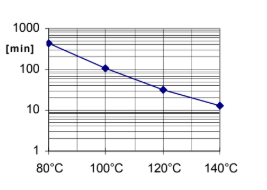

Fig 3.2 : Geltime as a function of temperature System : MY 740 / HY 906 / DY 073-1 (100:80:1 phr) ( measured with a Gelnorm Instrument, ISO 9396)

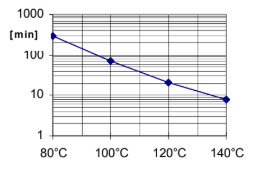

Fig 3.3 : Geltime as a function of temperature System: MY 740 / HY 906 / DY 073-1 (100:80:2 phr) ( measured with a Gelnorm Instrument, ISO 9396)

- Electrical Properties

Determined on standard test specimen at 23°C

Cured for 6h at 100°C + 12h at 135°C + 3h at 160°CKey Value Unit Test Mehod Breakdown strength 26 - 30 kV/mm IEC 60243-1 Tracking resistance > 600-0.0 CTI IEC 60112 Tracking resistance (Test Solution A) > 600M-0.0 CTI IEC 60112 Electrolytic corrosion A-1 grade IEC 60246

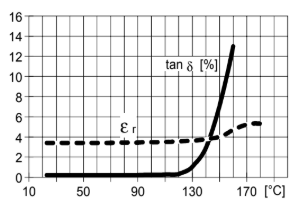

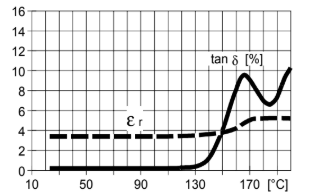

Fig.4.1: Loss factor (tan δ) and dielectric constant (εr) as a function of temperature (measurement frequency: 50 Hz , IEC 60250)

Curing Cycle: 6h at 100°C + 12h at 135°C

Fig.4.2: Loss factor (tan δ) and dielectric constant (εr) as a function of temperature (measurement frequency: 50 Hz, IEC 60250)

Curing Cycle: 6h at 100°C + 12h at 135°C + 3h at 160°C

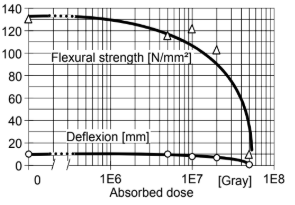

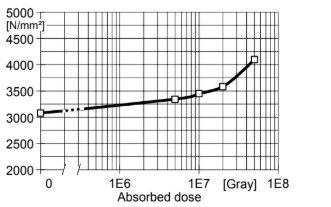

- Resistance Against Gamma Radiation

Gamma dose rate: 1- 2·10⁶ Gray/h Irradiation medium: Water Irradiation temperature: 30 - 40°C

Fig.5.1: Ultimate flexural strength and deflection at break as a function of the radiation (ASTM D 790)

Fig.5.2: Modulus of elasticity from Flexural Test as a function of the radiation (ASTM D 790)

Safety & Health

- Handling Precautions

Personal hygiene Safety precautions at workplace protective clothing overalls gloves essential arm protectors recommended when skin contact likely goggles/safety glasses yes Skin protection before starting work Apply barrier cream to exposed skin after washing Apply barrier or nourishing cream Cleansing of contaminated skin Dab off with absorbent paper, wash with warm water

and alkali-free soap, then dry with disposable towels.

Do not use solventsDisposal of spillage Soak up with sawdust or cotton waste and deposit in

plastic-lined binVentilation of workshop Renew air 3 to 5 times an hour Ventilation of workplaces Exhaust fans. Operatives should avoid inhaling

vapoursFirst Aid : Contamination of the eyes by resin, hardener or mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately. Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

Storage & Handling

- Storage Conditions

Store the components at 18-25°C, in tightly sealed and dry original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Product specific advise regarding storage can be found on product label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.001 %(W) %(W) Accelerator : Resin Mix Ratio 0.8 %(W) %(W) Hardener : Resin