Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Hardener, Resins, Binders & Matrix Materials

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

- Low viscosity and good impregnation capability

- Solvent free system

- Long pot-life due to high latency (in absence of tape catalyst)

- Good impregnating bath stability, even at elevated temperatures

- Excellent mechanical and electrical end properties.

- Thermal class H according IEC 60216

- ARALDITE® MY 790-1 CH and ARADUR® HY 1102 system is best used in combination with mica tapes containing ACCELERATORs. It offers excellent compatibility with the epoxy/anhydride catalysts presently in common use. The previously vacuum-dried machines or machine components are immersed in the ARALDITE® MY 790-1 CH/ ARADUR® HY 1102 bath and first impregnated under vacuum, then under pressure. The parts to be insulated are wrapped with ACCELERATOR-containing mica tape. The chemical reaction of the epoxy resin and the anhydride curing agent only takes place in these areas. The low-viscosity reactive resin mix drains out of sections which do not contain an ACCELERATOR. The resin is cured in forced-air ovens at temperatures around 150°C. The length of time required for cross linking depends on the type of reaction ACCELERATOR used.

- Key Properties

- Low viscosity and good impregnation capability

- Solvent free system

- Long pot-life due to high latency (in absence of tape catalyst)

- Good impregnating bath stability, even at elevated temperatures

- Excellent mechanical and electrical end properties.

- Thermal class H according IEC 60216

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Applications

Full-bath impregnation of motors and generators with medium and high power ratings and impregnation of single conductors (Roebel bars) in combination with mica tapes

- Application Details

Full-bath impregnation of motors and generators with medium and high power ratings and impregnation of single conductors (Roebel bars) in combination with mica tapes

Properties

- Physical Form

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Reactive Mix Properties

Mixture of 100 pbw Araldite MY 790-1 CH / 120 pbw Aradur HY 1102

Viscosity at 70°C

mPa s

16 -19*

vis cosity increase after 20 h / 100°C

mPa s

< 1.4

Viscosity measured with Hoeppler VST 1000 * specified value

Mixture of 100 pbw Araldite MY 790-1 CH / 100 pbw Aradur HY 1102

Viscosity at 60°C

mPa s

<31

viscosity increase after 20 h / 100°C

mPa s

<2.2

Viscosity measured with Brookfield LVT with UL Adapter 304

Viscosity of 1:1 mixture after storage 10 days at 60°C measured at 60°C with Hoeppler: < 35 mPa s

- Electrical Properties Graphs

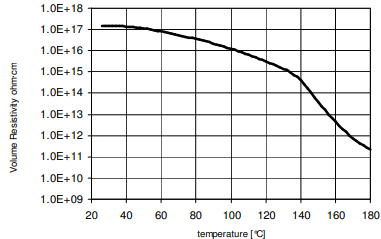

Volume resistivity (ρ) as a function of temperature (measurement voltage: 1000 V, IEC 60093/ DIN 53482)

Processing MethodsVacuum Pressure Impregnation (VPI - process)

Properties of Cured CompoundsDependence of cured compound properties on resin/curing agent mixing ratio The fact that the vapor pressure of the curing agent is somewhat higher than that of the resin leads to slight

variations in the ratio of resin to curing agent in various sections of the cured compound, particularly in the case of insulated parts having large surface area.Effect of various mixing ratios on the glass transition temperature (Tg) after cure 16h 90°C + 10h 140°C.

ACCELERATOR DY 9577 (0.16 pbw) and DY 073-1 (0.04 pbw), were used to determine these results.

100 pbw ARALDITE MY 790-1 CH : 90 pbw ARADUR® HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 142°C

100 pbw ARALDITE MY 790-1 CH : 95 pbw ARADUR® HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 144°C

100 pbw ARALDITE MY 790-1 CH : 100 pbw ARADUR® HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 144°C

100 pbw ARALDITE MY 790-1 CH : 105 pbw ARADUR® HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 143°C

100 pbw ARALDITE MY 790-1 CH : 110 pbw ARADUR® HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 140°CElectrical PropertiesDetermined on unreinforced, cast standard test specimen at 23°C

Cured for 16h 90°C + 10h 140°CProperty

Value

Unit

Test Method

Condition

Breakdown Strength

24 - 28

[kV/mm]

IEC 60243-1

-

Tracking Resistance with Test Solution A

> 600

[CTI]

IEC 60112

Test Solution A

Tracking Resistance with Test Solution B

> 600M

[CTI]

IEC 60112

Test Solution B

HV Arc Resistance

60 - 75

[s]

IEC 61621

-

Fig. 5.1 Volume resistivity (ρ) as a function of temperature (measurement voltage: 1000 V, IEC 60093/ DIN 53482)

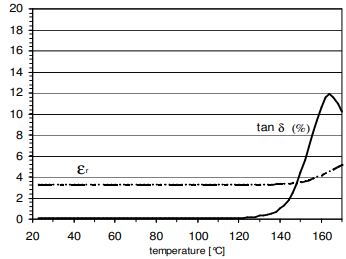

Fig 5.2 Loss factor (tan δ) as a function of temperature (measurement frequency: 50 Hz, IEC 60250/ DIN 53483)

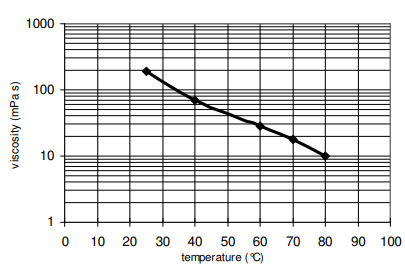

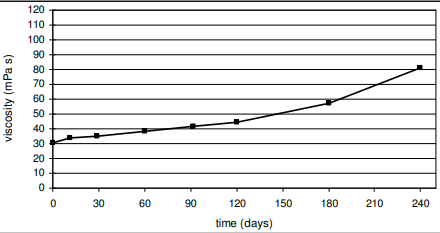

Processing GuidelinesViscosity: System: Araldite MY 790-1 CH / Aradur HY 1102 (100:100 pbw)

Figure 3.1: Initial viscosity vs. temperature without accelerator (measurements with Hoeppler VST 1000)

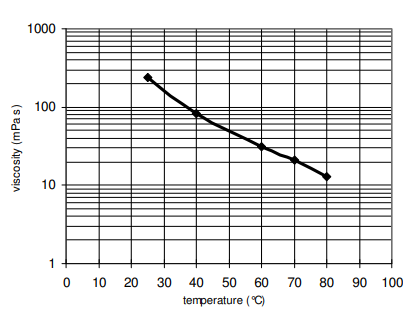

System: Araldite MY 790-1 CH / Aradur HY 1102 (100:120 pbw)

Figure 3.2: Initial viscosity vs. temperature without accelerator (measurements with Hoeppler VST 1000)

Product OverviewAraldite® MY 790-1 CH and Aradur® HY 1102 system is best used in combination with mica tapes containing accelerators. It offers excellent compatibility with the epoxy/anhydride catalysts presently in common use. The previously vacuum-dried machines or machine components are immersed in the Araldite® MY 790-1 CH/ Aradur® HY 1102 bath and first impregnated under vacuum, then under pressure. The parts to be insulated are wrapped with accelerator-containing mica tape. The chemical reaction of the epoxy resin and the anhydride curing agent only takes place in these areas. The low-viscosity reactive resin mix drains out of sections which do not contain an accelerator.

The resin is cured in forced-air ovens at temperatures around 150°C. The length of time required for cross linking depends on the type of reaction accelerator used.

Viscosity Build Up GraphMixture of 100 pbw Araldite MY 790-1 CH / 100 pbw Aradur HY 1102

Mechanical & Physical Properties

Mechanical & Physical PropertiesDetermined on unreinforced, cast standard test specimen at 23°C

System: Araldite MY 790-1 CH / Aradur HY1102 / DY 9577 / DY 073-1 (100:100:0.16:0.04 pbw)

Cured for 16h 90°C + 10h 140°CProperty

Value

Unit

Test Method

Condition

Tensile Strength

40 - 50

[MPa]

ISO 527

-

Elongation at Break

1.5 - 2.0

[%]

ISO 527

-

E Modulus from Tensile Test

2800 - 3400

[MPa]

ISO 527

-

Flexural Strength at 23°C

125 - 135

[MPa]

ISO 178

23°C

Surface Strain at 23°C

4.5 - 5.5

[%]

ISO 178

23°C

E Modulus from Flexural Test

2800 - 3400

[MPa]

ISO 178

23°C

Glass Transition Temperature (DSC)

140 - 150

[°C]

ISO 11357-2

-

Coefficient of Linear Thermal Expansion (20-80°C)

67 - 70

[ppm/K]

ISO 11359-2

20 - 80°C

Thermal Conductivity

0.15 - 0.20

[W/mK]

ISO 8894-1

-

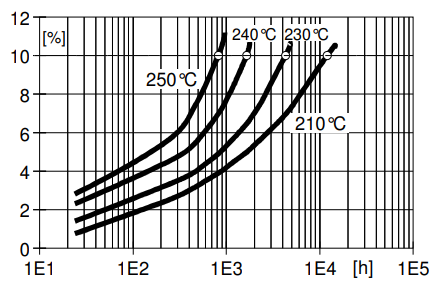

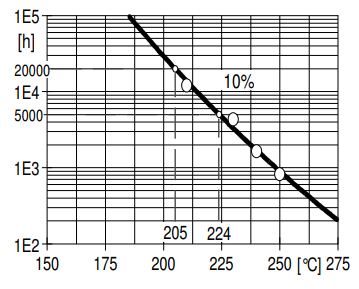

Thermal Endurance Profile (TEP), Temperature Index (TI)

205 / 224

[°C]

IEC 60216

20,000 / 5,000 h

Thermal Ageing Class (20,000 h)

H

-

IEC 60085

-

Water Absorption (50x50x4 mm specimen) - 10 days at 23°C

0.30 - 0.40

[% by wt]

ISO 62

23°C

Water Absorption (50x50x4 mm specimen)- 60 min at 100°C

0.15 - 0.20

[% by wt]

ISO 62

100°C

Density at 25°C

1.14 - 1.16

[g/cm³]

ISO 1183

25°C

Decomposition Temperature (Heating rate: 10K/min)

> 350

[°C]

DTA

-

* values measured with MY 790-1 CH / HY 1102/DY 9577 / DY 073-1 (100:90:0.16:0.04 pbw)

Fig.5.1: Weight loss (specimen: 50×50×3 mm) (limit: 10%)

Fig.5.2: Temperature Index 205 / 224 (weight loss 10 %)

Typical Cured PropertiesDependence of cured compound properties on resin/curing agent mixing ratio The fact that the vapor pressure of the curing agent is somewhat higher than that of the resin leads to slight variations in the ratio of resin to curing agent in various sections of the cured compound, particularly in the case of insulated parts having large surface area.

The following table shows the effect of various mixing ratios on the glass transition temperature (Tg) after cure 16h 90°C + 10h 140°C.

- Accelerator DY 9577 (0.16 pbw) and DY 073-1 (0.04 pbw), were used to determine these results.

- 100 pbw Araldite MY 790-1 CH : 90 pbw Aradur HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 142°C

- 100 pbw Araldite MY 790-1 CH : 95 pbw Aradur HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 144°C

- 100 pbw Araldite MY 790-1 CH : 100 pbw Aradur HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 144°C

- 100 pbw Araldite MY 790-1 CH : 105 pbw Aradur HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 143°C

- 100 pbw Araldite MY 790-1 CH : 110 pbw Aradur HY 1102 : 0.16 pbw DY 9577 / 0.04 pbw DY 073-1 Tg = 140°C

Safety & Health

- Safety Precautions

When working with chemical substances such as epoxy resins, comprehensive safety measures must be in place to ensure the well-being of personnel and maintain a clean work environment. Protective clothing and goggles or safety glasses are mandatory, while gloves are essential to prevent direct skin contact. Arm protectors are recommended when skin exposure is likely, and a respirator or dust mask should be used when airborne particles or vapours are present. For skin protection, apply a barrier cream to exposed areas before starting work, and after washing, use a barrier or nourishing cream to keep skin healthy. In the event of contamination, affected skin should be dabbed with absorbent paper, washed with warm water and alkali-free soap, and dried with disposable towels—solvents must not be used. A clean workspace is also crucial: cover workbenches with light-coloured paper and use disposable beakers and equipment. Any spillage should be soaked up with sawdust or cotton waste and disposed of in a plastic-lined bin. Adequate ventilation is essential for safety—renew workshop air 3 to 5 times an hour, and use exhaust fans in the workplace. Operatives must take care to avoid inhaling vapours, ensuring a safe and controlled working environment.

Contamination of the eyes by resin, hardener or casting mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately.

- Handling Precautions

Protective clothing : yes

Gloves : essential

Arm protectors : recommended when skin contact likely

Goggles/safety glasses : yes

Skin protection before starting work : Apply barrier cream to exposed skin

After washing : Apply barrier or nourishing cream

Cleansing of contaminated : skin Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Disposal of spillage : Soak up with sawdust or cotton waste and deposit in plastic-lined bin

Ventilation of workshop :Renew air 3 to 5 times an hour

Ventilation of workplaces: Exhaust fans. Operatives should avoid inhaling vapours- Industrial Hygiene

Mandatory and recommended industrial hygiene procedures should be followed when- ever our products are being handled and processed.

- First Aid

- Contamination of the eyes by resin, hardener or mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted.

- Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately.

- Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

Storage & Handling

- Storage Conditions

Storage Araldite® MY 790-1 CH and Aradur® HY 1102, according to the storage conditions on the product label and in tightly sealed and dry original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Product specific advice regarding storage can be found on product label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use. To eliminate any clouding (crystallization) which might have occurred, heat to 55 - 65°C for several hours. For information on waste disposal and hazardous products of decomposition in the event of fire, refer to the Material Safety Data Sheets (MSDS) for these particular products.

- Storage Information

Storage ARALDITE®MY 790-1 CH and ARADUR® HY 1102, according to the storage conditions on the product label and in tightly sealed and dry original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Product specific advice regarding storage can be found on product label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use. To eliminate any clouding (crystallization) which might have occurred, heat to 55 - 65°C for several hours.