Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- 2K (2 Component) Potting Compound

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Features

- Low viscosity

- Long working life at ambient temperature

- Good mechanical properties

- Good electrical properties

- UL 94 V0 compliant at 6 mm

- Features and Benefits

- Low viscosity

- Long working life at ambient temperature

- Good mechanical properties

- Good electrical properties

- UL 94 V0 compliant at 6 mm

Applications & Uses

- Application Area

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

Properties

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Information

Curing Requirement :

It is recommended to cure the Arathane® 5888 IS / Arathane® 5888 PO system at moderate temperatures in order to achieve full physical properties. For example, it can be cast in pre-heated molds at temperatures of 30-50°C. Full properties can be achieved by curing for 6 hours at 80°C.

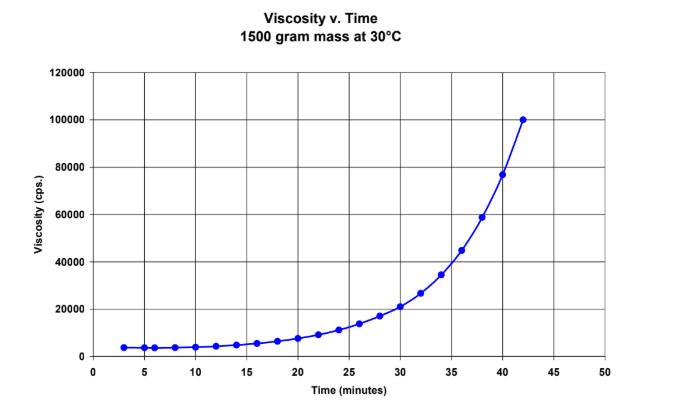

Working Life :

- Processing Guidelines

The Arathane® 5888 IS and Arathane® 5888 PO components are mixed according to the specific ratio at ambient temperature, preferably using automatic dosing and mixing equipment. If the Arathane® 5888 PO component has been stored for an extended time, it is recommended to stir well the complete content of the container. The fillers present in Arathane® 5888 IS and Arathane® 5888 PO have a tendency to separate during extended storage. This may be prevented by periodic slow agitation of the containers.

- Mix ratio by weight (Arathane® 5888 IS / Arathane® 5888 PO) : 13 / 100

- Mix ratio by volume (Arathane® 5888 IS / Arathane® 5888 PO) : 17.2 / 100

- Initial mixed viscosity, 25°C, cps (mPas) : 4,000 – 5,000

- Processing Characteristics

- The Arathane® 5888 IS and Arathane® 5888 PO components are mixed according to the specific ratio at ambient temperature, preferably using automatic dosing and mixing equipment.

- If the Arathane® 5888 PO component has been stored for an extended time, it is recommended to stir well the complete content of the container.

- The fillers present in Arathane® 5888 IS and Arathane® 5888 PO have a tendency to separate during extended storage. This may be prevented by periodic slow agitation of the containers.

- Cure Requirements

It is recommended to cure the Arathane® 5888 IS / Arathane® 5888 PO system at moderate temperatures in order to achieve full physical properties. For example, it can be cast in pre-heated molds at temperatures of 30-50°C. Full properties can be achieved by curing for 6 hours at 80°C.

Storage & Handling

- Storage Information

- Arathane® 5888 IS US (isocyanate component) should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 18°C (36°F and 64°F).

- Under these storage conditions the shelf life is 6 months from the date of manufacture. Tightly reseal container immediately after use.

- Purging the partially used containers with dry nitrogen is strongly recommended because Arathane® 5888 IS US is very moisture sensitive.

- The product should not be exposed to direct sunlight.

- Arathane® 5888 PO US (polyol component) should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F).

- Under these storage conditions the shelf life is 6 months from the date of manufacture.

- The product should not be exposed to direct sunlight.

- Storage Conditions

Arathane® 5888 IS US (isocyanate component) should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 18°C (36°F and 64°F). Under these storage conditions the shelf life is 6 months from the date of manufacture. Tightly reseal container immediately after use. Purging the partially used containers with dry nitrogen is strongly recommended because Arathane® 5888 IS US is very moisture sensitive The product should not be exposed to direct sunlight.

Arathane® 5888 PO US (polyol component) should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 6 months from the date of manufacture. The product should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.13 %(W) %(W) Hardener : Resin