Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resin,Curing Agent

- Plastics & Elastomers Functions

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application Information

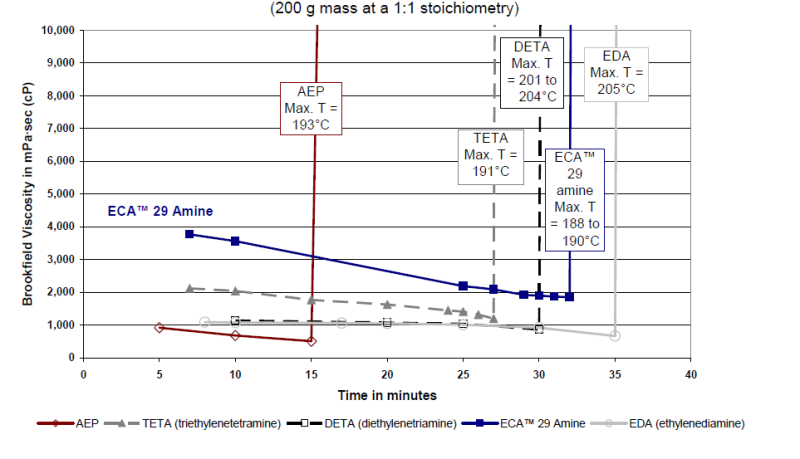

- Epoxy Curing Agent ECA 29 can be of particular utility in applications where TETA (triethylenetetramine) cannot provide sufficiently long pot-life or sufficiently high Tg (glass transition temperature) when used to cure standard liquid epoxy resins. Another advantage of this product is that it produces considerably lower maximum exotherm temperatures than TETA when cured in thick sections, thus pointing to particularly utility when molding large castings or composites since it may allow molding in thicker sections or at higher component temperatures, thus allowing faster infusion of epoxy formulations into various types of reinforcements used to form composite materials.

- The mechanical properties and glass transition temperatures of epoxy resins cured with Epoxy Curing Agent ECA 29 to form unfilled, cast sheets, are shown in the following table. The numbers given in parentheses are the coefficients of variation of the property values.

- Properties of a standard liquid epoxy resin (EEW = 186) cured with 19.9 phr of Epoxy Curing Agent ECA 29 amine, baked 3 hours at 80°C + 2 hours at 135°C:

Tensile Strength, ultimate 9,860 psi (4.16) 68.0 MPa Tensile Modulus 372,000 psi (1.22)

2.56 GPa % Elongation at Break 5.37 (10.2) 5.37 Flexural Strength 13,900 psi (0.46)

95.8 MPa Flexural Modulus 381,000 psi (0.67)

2.63 GPa

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Viscosity vs. Time for Various Amines and Standard DGEBA Resin

Safety & Health

- Toxicity and Safety

- Because of the fragility of eye tissue, almost any eye contact with any ethyleneamine may cause irreparable damage, even blindness. A single, short exposure to ethyleneamines, may cause severe skin burns, while a single, prolonged exposure may result in the material being absorbed through the skin in harmful amounts. Exposures have caused allergic skin reactions in some individuals. Single dose oral toxicity of ethyleneamines is low. The oral LD50 for rats is in the range of 1000 to 4500 mg/kg for the ethyleneamines.

- The principal hazards that arise in working with Epoxy Curing Agent ECA 29 are those associated with similar organic amines; namely, a corrosive action on skin and eyes. Precautions should be taken to prevent contact with these parts of the body such as by use of protective clothing and chemical goggles. If contact occurs, immediately flush the exposed area with plenty of water for at least 15 minutes. Eye exposures should be examined by a physician. Contaminated clothing should be laundered before reuse. If ingestion occurs, do not induce vomiting. Have the individual drink a large amount of water (or milk, if it is readily available) and transport them to a medical facility immediately.

Packaging & Availability

- Packaging Information

Epoxy Curing Agent ECA 29 is available in bulk and in 55-gallon drums of 205 Kg net weight.

Storage & Handling

- Storage Informatin

- Because of the fragility of eye tissue, almost any eye contact with any ethyleneamine may cause irreparable damage, even blindness. A single, short exposure to ethyleneamines, may cause severe skin burns, while a single, prolonged exposure may result in the material being absorbed through the skin in harmful amounts. Exposures have caused allergic skin reactions in some individuals. Single dose oral toxicity of ethyleneamines is low. The oral LD50 for rats is in the range of 1000 to 4500 mg/kg for the ethyleneamines.

- The principal hazards that arise in working with Epoxy Curing Agent ECA 29 are those associated with similar organic amines; namely, a corrosive action on skin and eyes. Precautions should be taken to prevent contact with these parts of the body such as by use of protective clothing and chemical goggles. If contact occurs, immediately flush the exposed area with plenty of water for at least 15 minutes. Eye exposures should be examined by a physician. Contaminated clothing should be laundered before reuse. If ingestion occurs, do not induce vomiting. Have the individual drink a large amount of water (or milk, if it is readily available) and transport them to a medical facility immediately.

Other

- Appearance

- Amber to brown clear liquid

- Chemical Properties

Value Units Test Method / Conditions Amine Value 1200.0-1300.0 mg KOH/g mg KOH/g ST-31.173 pH 11.6 - - Physical Properties

Value Units Test Method / Conditions Boiling Point 250.0 °C °C Density 1.01 g/mL g/mL Flash Point max. 182.0 °C °C Pensky-Martens Closed Cup (PMCC) Specific Gravity 1.01 -