Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Function

- Reactive Diluent,Reactive Diluent

- Plastics & Elastomers Functions

- Single Ingredient

- Yes

- Synonyms

- 1,4-Bis(2,3-Epoxypropoxy)Butane, B14DODGE

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- ERISYS® GE-21 epoxidized Butanediol is a low viscosity, aliphatic diepoxide. It is intended for use as a reactive diluent for high viscosity epoxy resins.

- ERISYS® GE-21 epoxidized Butanediol is compatible at all concentrations with those resins and resin/diluent blends can be cured using any epoxy resin curing agent. As a result of its chemical structure ERISYS® GE-21 epoxidized Butanediol is not as efficient in viscosity reduction as the aliphatic monofunctional reactive diluents ERISYS® GE-5, GE-6, GE7, and GE-8. However, the performance properties of epoxy formulations diluted with ERISYS® GE-21 are modified to a lesser degree than those of systems containing the aliphatic monofunctional diluents.

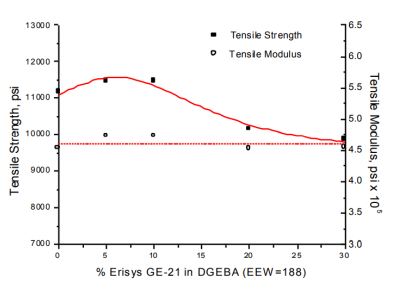

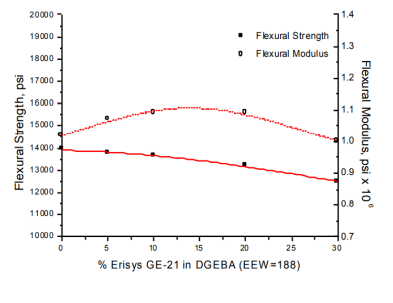

- Depending on concentration, properties such as gel time, strength, and modulus of an ERISYS® GE-21 epoxidized Butanediol diluted formulation remains relatively unchanged compared to an undiluted resin.

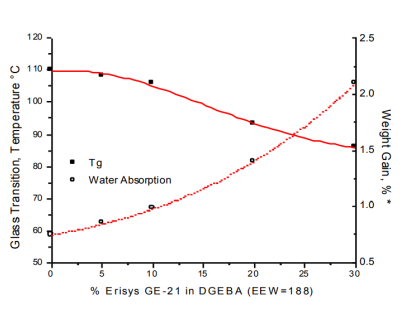

- The difunctionality of ERISYS® GE -21 epoxidized Butanediol helps to produce formulations with improved chemical and heat resistance compared to formulations containing monofunctional diluents.

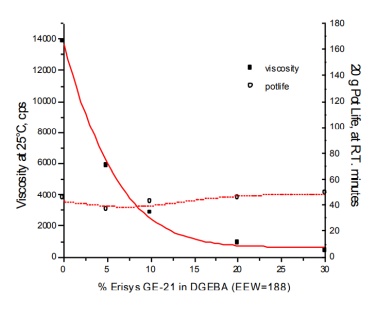

- ERISYS® GE-21 epoxidized Butanediol does not affect the pot life of precatalyzed epoxy resin/acid anhydride formulations. Formulations containing this product exhibit excellent wettability making them ideal candidates for composite and impregnation applications.

- ERISYS® GE-21 epoxidized Butanediol has low moisture, hydrolyzable chloride and residual epichlorohydrin contents. Its exceptionally low color makes it the epoxidized Butanediol diluent of choice in color critical applications.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Application Information

- Filament Winding

- Concrete/Civil Engineering Adhesives

- Laminating/Assembly Adhesives

- Structural Adhesives

- Vacuum Pressure Impregnation (VPI)

- Electronic Encapsulants

- Flooring

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Handling Properties

The use of ERISYS® GE-21 epoxidized Butanediol will affect the handling and cured properties of resin formulations. The effects of these changes are shown below.

- Viscosity and Pot life

- Tg and Moisture Pickup

- Tensile Properties

The effect of ERISYS® GE-21 epoxidized Butanediol on the cured properties of liquid epoxy resin (EEW 188) cured with TETA.

- Flexural Properties

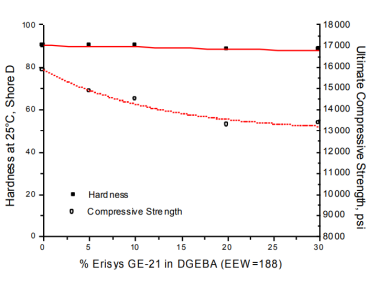

- Hardness and Compressive Strength

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ERISYS® GE-21 Resin should be stored in a dry place, in the sealed original containers, at temperatures between +2°C and +40°C (+35.6°F and +104°F).

- Under these storage conditions, the product has a shelf life of 24 months (from date of manufacture).

- The products should not be exposed to direct sunlight.

Other

- Appearance

- Clear, clean

- Color (SDS)

- Clear Light Yellow

- Odor (SDS)

- Pungent

- Physical Properties

Value Units Test Method / Conditions Density 9.1-9.3 lb/gal lb/gal At 25°C Flash Point min. 110.0 °C °C Viscosity 10.0-18.0 cPs cPs At 25°C