Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Binder & Resin,Resins, Binders & Matrix Materials

- Single Ingredient

- Yes

- Technologies

- Product Families

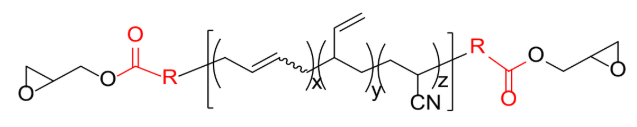

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

Applications & Uses

- Adhesive & Sealant End Applications

- Coating End Applications

- Compatible Polymers & Resins

- Composites End Use

- Application Information

HYPRO® 1300X68 ETBN reactive liquid polymer is suggested for use as a toughener in fiber-reinforced products, adhesives, molding compounds, potting and encapsulating compounds and chemical-resistant coatings. HYPRO® 1300X68 ETBN reactive liquid polymer can be blended with other components to achieve the degree of toughening required.

- Molding compounds

- Industrial adhesives

- Impact resistance coatings

- Thermocycling modifier for epoxies

- Toughening of prepregs, composites and structural adhesives

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Test Data

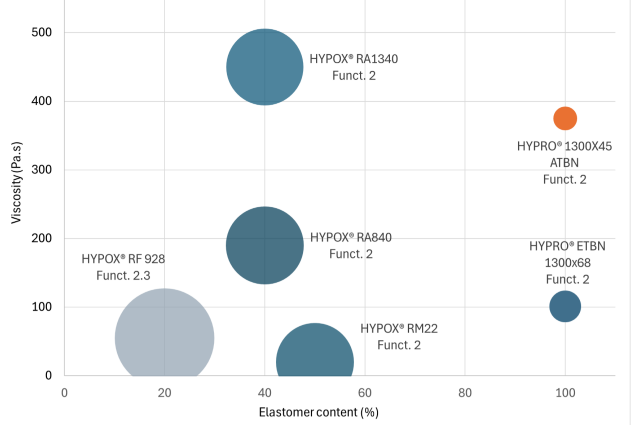

Size of bubble proportional to reactive group index

Properties of Untoughened versus Toughened with HYPRO® 1300X68 ETBN

Property Baseline Formulation Untoughened Toughened with 7.5% of HYPRO® 1300X68 ETBN

Lap Shear Strength - Aluminium L165 3,267.7 ± 275.6 psi (22.53 ± 1.9 MPa) 4141.3 ± 261.1 psi (28.56 ± 1.8 MPa)

Fracture Toughness G1C 285 ± 48 J/m² 686 ± 28 J/m² Flexural Elongation at Break 5.6 ± 0.8 % 7.3 ± 0.9 % Max Flexural Strength 18,289.3 ± 754.2 psi (126.1 ± 5.2 MPa) 15,823.6 ± 217.6 psi (109.1 ± 1.5 MPa)

Tg – DSC Midpoint 289.4 °F (143 °C) 284.0 °F (140 °C)

Viscosity 28,750 cP 31,250 cP Note:

* All values are measured at ambient temperature.

** DICY - Bisphenol A Epoxy based 1K formulation with 2% fumed silica, cured 2h 120°C + 2h 150°C.

*** The baseline formulation toughened with 7.5% of ETBN and cured at the same condition.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

HYPRO® 1300X68 ETBN reactive liquid polymer material should be stored in a dry place, in the sealed original containers, at temperatures between +2°C and +40°C (+35.6°F and +104°F). Under these storage conditions, the product has a shelf life of 6 months (from date of manufacture). The products should not be exposed to direct sunlight.

Other

- Appearance

- Clear, slightly hazy

- Color (SDS)

- Yellow brown

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Equivalent Weight 230.0 kg/eq kg/eq - Physical Properties

Value Units Test Method / Conditions Flash Point min. 200.0 °C °C DIN 51758 Viscosity 10000.0-20000.0 cPs cPs At 50°C Viscosity 10000.0-20000.0 cPs cPs Falling Ball Viscometer at 50°C Viscosity 10000.0-20000.0 cPs cPs ISO 12058 at 50°C