Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Foaming Agent

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Features and Benefits

Features

- JEFFADD® AS-76 aldehyde scavenger is an amine based scavenging technology, that when introduced into the formulated B-side, will uniformly mix without separation.The product can be introduced into various grades of polyester or polyether flexible slabstock and high resiliency molded polyurethane foam for automotive applications to help reduce the aldehyde content in the final polyurethane foam.

Benefits

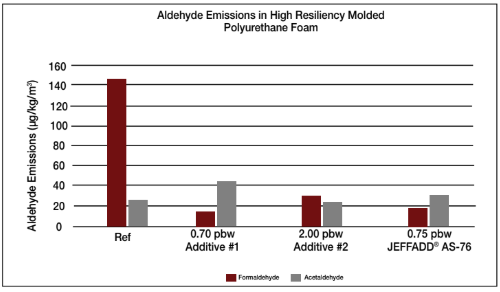

- Aldehyde Reduction - Aldehyde scavenging technologies reduce the formaldehyde emission, while negatively impacting the acetaldehyde. JEFFADD® AS-76 aldehyde scavenger effectively helps reduce the formaldehyde emission without compromising the acetaldehyde levels.

- Low Freezing Point - JEFFADD® AS-76 aldehyde scavenger has a freezing point of -18°C, allowing the product to outperform under stringent temperatures..

- Minimal Re-formulation – Introducing new polyurethane additives welcomes major polyurethane system re-formulation efforts. JEFFADD® AS-76 aldehyde scavenger helps minimize the polyurethane system re-formulation effort.

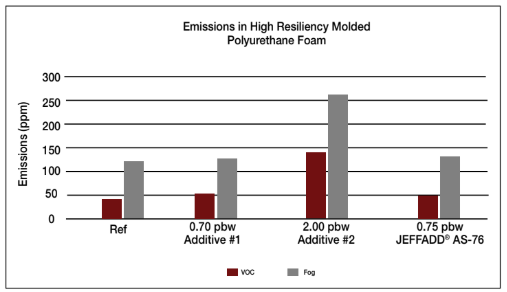

- No VDA-276 Emission Impact – It is important to maintain low emission levels for specialized polyurethane formulations. JEFFADD® AS-76 aldehyde scavenger does not contribute to the overall emissions of the final polyurethane foam.

- Wide Processing Window - Many aldehyde scavengers generate narrow processing windows. JEFFADD® AS-76 aldehyde scavenger helps to widen the processing window, allowing for better foam processing with MDI, TDI and various isocyanate blend ratios.

Applications & Uses

- Industrial Additives End Use

- Markets

- Applications

- Use Rate

Based on our in-house test condition results, JEFFADD® AS-76 aldehyde scavenger can be best introduced at a 0.75 pbw usage level into the formulated B-side polyurethane resin and adjust the usage level accordingly to meet your processing and VDA-276 emission targets. Laboratory results have demonstrated that JEFFADD® AS-76 aldehyde scavenger does not affect the stability of a standard formulated polyurethane system when stored between 20ºC and 50ºC.

Properties

- Physical Form

- Soluble In

Regulatory & Compliance

Technical Details & Test Data

- Application Graphs

Aldehyde emission comparison under VDA-276 testing conditions (4 hours conditioning, 0.4 air exchanges/hr. and 5% relative humidity)

Emission comparison under VDA-278 testing conditions (30min. at 90°C for VOC / 60min. at 120°C for Fog, headspace testing)

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

JEFFADD® AS-76 aldehyde scavenger has been tested in an in-house developed metal corrosion test. Based on these internal test results, it is highly recommended to avoid the use of carbon steel and zinc coated steel-based equipment. Thorough evaluation of JEFFADD® AS-76 aldehyde scavenger is recommended to determine the compatibility in the desired formulated PU system. Ensure that all aspects of the formulated PU system, PU manufacturing process and storage have been evaluated (i.e. corrosivity, PU foam reactivity profile, PU resin stability, etc.).

Improved Product Shelf Life - JEFFADD® AS-76 aldehyde scavenger has a shelf life of 2 years and offers an extended product shelf life compared to other product offerings.

Other

- Appearance (SDS)

- Light yellow liquid

- Color (SDS)

- Light yellow

- Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value1 3624.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Boiling Point 100.0 °C °C initial boiling point Specific Gravity 1.09 - at 20/20°C