Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Fluids & Lubricants Features

- Product Benefits

- Easily Formulated

- Low to mild staining on aluminum

- Inherently low foaming

- Low cobalt and copper leaching

- Source of alkalinity

- Good pH buffer in water-miscible metalworking fluids

Applications & Uses

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Markets

- Applications

- Product Applications

- JEFFADD® MW 760 amine can be used in water-miscible metalworking formulations. This amine should be added in combination with other water-soluble components. For formulation into emulsifiable oil and semi-synthetic formulations, emulsifier package should be adjusted. For some formulations containing a sodium sulfonate as the primary emulsifier, formulation viscosity may increase. We suggest adding in a glycol ether to help reduce the viscosity.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Aluminium Staining and Ferrous Corrosion

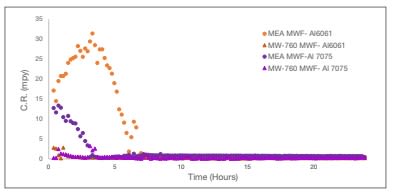

Linear Polarization Corrosion Results: Test Method: Probes are submersed in a 5% dilution of metalworking fluid. A constant current is placed on the fluid and corrosion rate (C.R.) is measured over time. The test is run for 24 hours.

Aluminum Leached into Fluid (ppm)

Amine MEA MW-760 Al 7075 58 2 AL 6061 38 11 Linear Polarization Resistance (LPR) Corrosion Test Chart (50°C for 24 Hours with Al 7075 and Al 6061)

- For JEFFADD® MW 760, highest corrosion rates are observed in the first hours of the test and passivation is achieved in about 2 hours.

- Formulation containing MEA shows much higher corrosion rates compared to JEFFADD® MW-760 and takes a longer time to achieve passivation.

- Lower staining is observed on probes for JEFFADD® MW-760 formulation compared to MEA formulation.

Ferrous Corrosion Inhibition

- Less amount of corrosion observed on formulation containing JEFFADD® MW-760 amine.

- No corrosion observed at 1.5% dilution of concentrate formulation.

- Formulating Tips

- JEFFADD® MW 760 amine can be incorporated into a formulation with the addition of an alcohol. In this case, Dodecanal is used.

- Addition of 6% glycol ether for JEFFADD® MW 760 amine was added for comparison to MEA. Viscosity of JEFFADD® MW-760 amine was at an acceptable viscosity without the addition of glycol ether.

Other

- Color (SDS)

- Water-white

- Odor (SDS)

- Amine-like