Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Catalyst

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Benefits

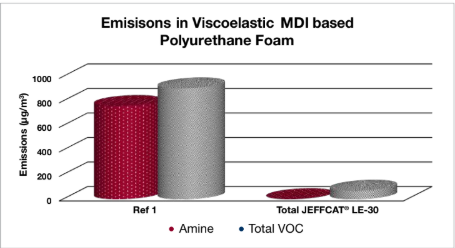

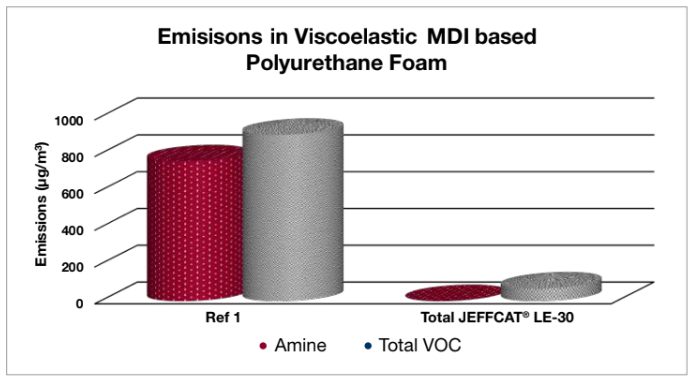

- Lower Polyurethane Foam Emissions – Utilizing JEFFCAT® LE-30 catalyst in a polyurethane formulation typically results in lower polyurethane foam emissions vs. conventional, non-reactive blowing amine catalysts.

- Lower Usage Level – Due to the potency of JEFFCAT® LE-30 catalyst, the usage level requirement is decreased when compared to other low emission amine blowing catalysts.

- Lower Polyurethane Foam Odor – Polyurethane foams produced with JEFFCAT® LE-30 catalyst have lower post-cure odor compared to conventional non-reactive blowing amine catalysts.

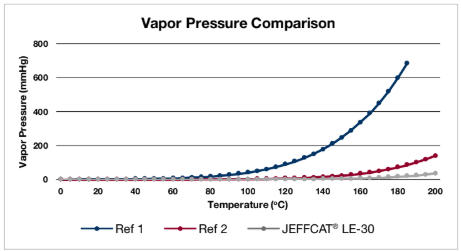

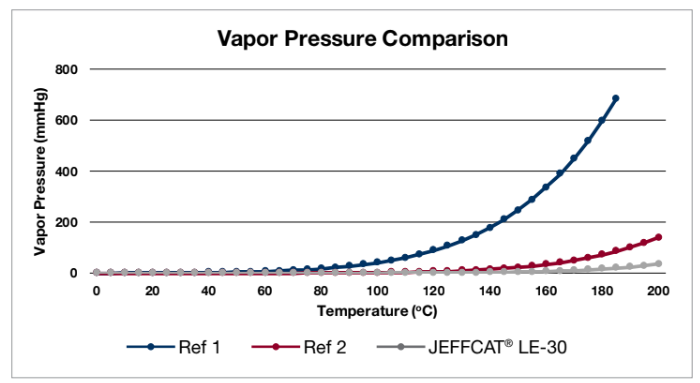

- Lower Vapor Pressure – JEFFCAT® LE-30 catalyst has a lower vapor pressure and can be used to replace high volatility, conventional non-reactive blowing amine catalysts.

Applications & Uses

- Industrial Additives End Use

- Use Rate

Initially introduce JEFFCAT® LE-30 catalyst into the formulated B-side polyurethane resin at a 0.50 pbw usage level, for a closed cell spray rigid polyurethane formulation and 0.80 pbw for an open cell spray rigid polyurethane formulation. For 2.80 pbw water polyether flexible slabstock formulations, a starting usage level of 0.10 pbw is recommended and 0.14 pbw for 4.00 pbw water polyether flexible slabstock formulations. A 0.30 pbw is recommended for polyester flexible slabstock formulations. In an MDI based viscoelastic formulation, it is recommended to use 0.17 pbw. Adjust the catalyst usage level accordingly to meet your processing needs.

- Application Guide

Introduce JEFFCAT® LE-30 catalyst into a polyether or polyester flexible slabstock, closed-cell or open-cell rigid spray or non- spray or viscoelastic polyurethane foam formulations as a co-catalyst.

Vapor pressure comparison of a conventional non-reactive and a low emission reactive amine blowing catalyst vs. JEFFCAT® LE-30 catalyst

VOC emission comparison of a conventional non-reactive amine blowing catalyst (Ref 1) vs. JEFFCAT® LE-30 catalyst (3-day pre-conditioning at 23oC chambering tesing conditions)

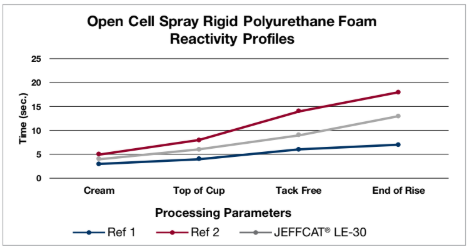

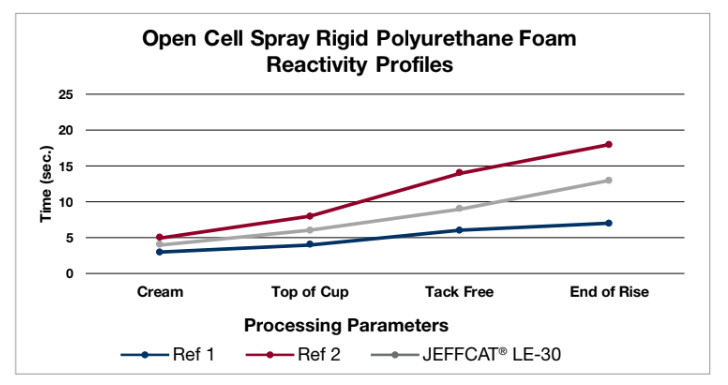

Reactivity profile comparison of a conventional non-reactive and a low emission amine catalyst vs. JEFFCAT® LE-30 catalyst at a 5.00 pbw catalyst usage level.

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Formulation Guide

Introduce JEFFCAT® LE-30 catalyst into a polyether or polyester flexible slabstock, closed-cell or open-cell rigid spray or non- spray or viscoelastic polyurethane foam formulations as a co-catalyst.

Figure 1: Vapor pressure comparison of a conventional non-reactive (Ref 1) and a low emission reactive (Ref 2) amine blowing catalyst vs. JEFFCAT® LE-30 catalyst.

Figure 2: VOC emission comparison of a conventional non-reactive amine blowing catalyst (Ref 1) vs. JEFFCAT® LE-30 catalyst (3-day pre-conditioning at 23oC chambering tesing conditions)

Figure 3: Reactivity profile comparison of a conventional non-reactive (Ref 1) and a low emission amine catalyst (Ref 2) vs. JEFFCAT® LE-30 catalyst at a 5.00 pbw catalyst usage level.

Packaging & Availability

- Regional Availability

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear

- Explosive Nature (SDS)

- Not explosive

- Odor (SDS)

- Amine like

- Oxidizing Properties (SDS)

- Not Oxidizing

- Physical Properties

Value Units Test Method / Conditions Boiling Point 241.0 °C °C Flash Point 313.0 °F °F Pensky-Martens Closed Cup (PMCC) Specific Gravity 0.9 - Viscosity 4.0 cSt cSt