Enhanced TDS

Identification & Functionality

- Blend

- No

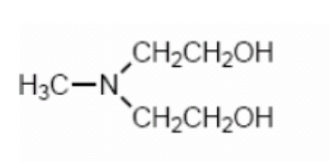

- CAS Number

- 105-59-9

- Chemical Family

- Chemical Name

- Function

- Solvent

- Industrial Additives Functions

- Single Ingredient

- Yes

- Synonyms

- MDEA

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Industrial Additives Features

- Labeling Claims

Applications & Uses

- Applicable Processes

- Markets

- Applications

- Application Details

The alkanolamines and their aqueous solutions will absorb carbon dioxide and hydrogen sulfide at lower temperatures and release the acid gases at higher temperatures. This forms the basis for processes which separate carbon dioxide and hydrogen sulfide from gas streams. JEFFTREAT® M solvent is used in tail gas treating and hydrogen sulfide enrichment units for selectively removing hydrogen sulfide from gas streams containing carbon dioxide. These units will, in most cases, permit 60 to 80% of the carbon dioxide to remain in the treated gas stream. JEFFTREAT® M solvent is also used in natural gas plants for the bulk removal of carbon dioxide while producing a gas stream containing 0.25 grains hydrogen sulfide/100 scf. Bulk carbon dioxide removal can be realized with JEFFTREAT® M solvent when the CO₂:H₂S ratio ranges from 100 to 1,000.

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Packaging Type

- Regional Availability

- Availability Information

JEFFTREAT® M solvent is currently available in 55-gallon drums, tank wagons, ISO containers, and tank cars.

Storage & Handling

- Storage Information

- The product should retain its conformance to sales specifications for a period of at least two years after date of manufacture if the product is stored at less than 100°F in its undamaged, unopened, factory packaged container.

- JEFFTREAT® M should not be stored in tanks made from zinc, galvanized steel, or copper and its alloys since the solvent will react with copper to form complex salts. Also avoid the use of elastomers such as Buna N, VITON® elastomer, neoprene, and nitrile as these materials tend to swell when exposed to the amine. KALREZ® 1050 LF elastomer performs satisfactorily in amine service as well as materials made from polypropylene and TEFLON® elastomer. A carbon steel storage tank, constructed according to a recognized code, is generally satisfactory. Carbon steel transfer lines, joined by welds or flanges, are suitable. Screw joints are subject to failure unless back-welded. FLEXITALLIC® gaskets work well for flanged connections. For pumps, a Durametallic Type RO-TT mechanical seal or equivalent is suitable.

Other

- Appearance

- Clear and substantially free of foreign matter

- Color (SDS)

- Colorless

- Odor (SDS)

- Ammoniacal

- Physical Properties

Value Units Test Method / Conditions Boiling Point 242.0 °C °C Density 8.69 lb/gal lb/gal Flash Point 140.0 °C °C Pensky-Martens Closed Cup (PMCC) Specific Gravity 1.04 - Viscosity 37.0 cSt cSt