Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Blend

- No

- Chemical Family

- Chemical Name

- Single Ingredient

- Yes

- Synonyms

- MDEA

- Technologies

- Product Families

Features & Benefits

- Base Chemicals Features

- Labeling Claims

- Product Features

- Lower Operating Costs

- Increased Processing Capacity

- Using Existing Treating Equipment

- Reduced Capital Cost for New Installations

- Improved Product Stability

- Lower Solvent Losses

- Reduced Corrosion

Applications & Uses

- Applicable Processes

- Markets

- Applications

- Application Information

- JEFFTREAT® MP-442 additive can be used for gas and liquid treating applications where JEFFTREAT® MP or a piperazine activated product is currently in use. It should also be considered for applications which currently use MDEA or formulated MDEA solvents, but require deeper CO₂ removal such as:

- Hydrogen Production Facilities

- Ammonia Plants

- Natural Gas Upgrading

- LNG Production.

- JEFFTREAT® MP-442 additive should be considered primarily for applications in which H₂S is not present or applications in which the mole ratio of CO₂ to H₂S in the untreated gas is very high. Huntsman recommends that a process evaluation be performed prior to the addition of any JEFFTREAT® MP-442 to a system.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

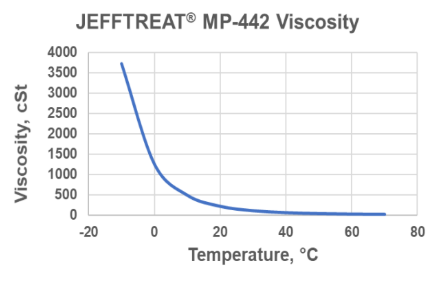

- Viscocity vs Temperature Graph

While crystals may start to form in the product at temperatures as high as 16.8°C, the product will remain easily pumpable at much lower temperatures. As the chart above shows, viscosity of the product begins to increase quickly at temperatures below about 0°C.

Packaging & Availability

Storage & Handling

- Storage Information

- The handling and storage of JEFFTREAT® MP-442 presents no unusual problems.

- The additive properties and alkaline nature of JEFFTREAT® MP-442 should be considered when choosing materials of construction. JEFFTREAT® MP-442 should not be stored in tanks made from zinc, galvanized steel, or copper and its alloys since the solvent will react with copper to form complex salts. Also avoid the use of elastomers such as Buna N, VITON® elastomer, Neoprene and nitrile as these materials tend to swell when exposed to the amine. Kalrez 1050 LF performs satisfactorily in amine service as well as materials made from polypropylene and TEFLON® elastomers.

- A carbon steel storage tank, constructed according to a recognized code, is generally satisfactory. Carbon steel transfer lines, joined by welds or flanges, are suitable. Screw joints are subject to failure unless backwelded. FLEXITALLIC® gaskets work well for flanged connections. For pumps, a Durametallic Type RO-TT mechanical seal, or equivalent is suitable.

Other

- Appearance

- Clear to slightly hazy liquid, substantially free of foreign matter

- Color (SDS)

- Yellow

- Odor (SDS)

- Amine-like

- Physical Properties

Value Units Test Method / Conditions Flash Point 100.0 °C °C Pensky-Martens Closed Cup (PMCC) Specific Gravity 1.05 - Viscosity 40.0 cSt cSt