Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

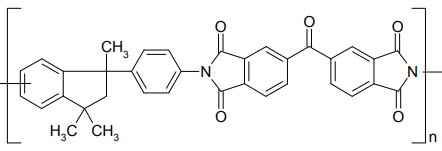

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Advantages

- Fully imidized

- Does not require high temperatures for processing

- Soluble in a variety of common solvents

- Excellent adhesion

- Durable and tough films

- Excellent chemical resistance

- Very good thermal properties

- 100% solid powder

Applications & Uses

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Formulating Information

- Dissolve Matrimid® 5218 in y-Butyrolactone solvent (20 percent solids). Use Hercules Magnamite AS4-12K graphite fibers to prepare unidirectional prepreg.

- B-stage prepreg in an air circulating oven with temperature starting at 77°F, increasing to 400°F. Keep the prepreg at 400°F for 45 - 60 minutes. The prepreg should then have the solvent retention necessary for flow during composite fabrication.

- A composite panel was prepared in the following manner:

Press mold: 500° - 600°F at 100 psi

Cool down: to room temp. at 100 psi

Dwell time: 30 min at 600°F Post cure: (free standing) 16 hrs. at 600°F - Special Features

Matrimid™ 9725 is a soluble thermoplastic polyimide. There is no polyamic acid precursor in the product that would require a high temperature cure to convert to the imide form. This lack of amic acid groups allows relatively simple processing compared to conventional polyamic acid precursor polyimides.

For example, when solutions of Matrimid™ 9725 are used for coating applications, the substrate need only be heated to a temperature and for a time sufficient to thoroughly remove the solvent. When the solvent has been removed, a strong, durable polyimide coating remains. By contrast, the more common polyamic acid precursor polyimides must be heated to high temperatures for long periods to convert the polyimide structure. This "curing" process evolves a water by-product and makes it very difficult to form pinhole-free coatings or void-free parts from those materials. No water is evolved in using Matrimid® 5218 because no curing (imidization) occurs during processing.

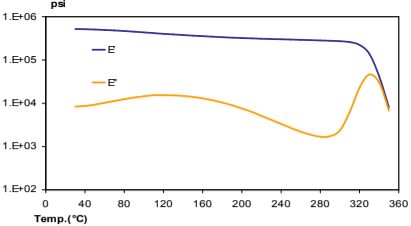

Matrimid™ 9725 has very unusual and desirable properties. Its high thermal stability and high glass transition temperature make Matrimid™ 9725 suitable for adhesive applications as well as matrix resin for composite applications. Figure 1 shows the change in modulus versus temperature of a neat resin molding based on Matrimid® 5218 (Dynamic Mechanical Analysis). Table 1 illustrates the adhesive properties of Matrimid® 5218 with a variety of substrates.

Matrimid® 5218 is soluble in many organic solvents and possesses excellent chemical resistance to water, steam, brine, acids, caustic and non-polar organic solvents, unlike other polyimides. As a soluble thermoplastic, Matrimid™ 9725 retains its solubility in certain polar organic solvents after processing, unless it has been thermally or chemically crosslinked before exposure to these solvents.

Matrimid™ 9725 is soluble in the following solvents. In general, 20 percent solutions are possible with these solvents.

- Mattere echlorde

- Chloroform

- Tetrachloroethane

- Tetrahydrofurane (THF)

- Dioxane

- Acetophenone

- Cyclohexanone

- m-Cresol

- γ-Butyrolactone

- imethylformamide (DMF)

- Dimethylacetamide (DMAC)

- N-methylpyrrolidone (NMP)

Substrate Adhesion minum,* mirror finish Excellent minum, Alodine treated Excellent Steel, hot or cold rolled Excellent Stainless steel Excellent Brass Excellent Titanium Excellent Copper, untreated Good Copper, etched with (NHa) S20. Excellent Glass, untreated Poor Glass, aminosilane treated Excellent Ryton® PPS (Phillips) untreated Poor Ryton PPS (Phillips) acid etched Excellent Kapton® (Du Pont) untreated Poor Kapton (Du Pont) acid etched Excellent * To obtain excellent adhesion to some aluminum surfaces a surfactant, such as 3M's Fluorad* FC 430, must be added to the polyimide vamish.

Figure1 Dynamic Mechanical Analysis of Matrimid 5218

Packaging & Availability

- Regional Availability

- Packaging Information

- Matrimid 5218 is supplied in 50 pound drums and Matrimid™ 9725 is supplied in 40 pound drums.

Storage & Handling

- Storage Condition

- This product should be stored in a dry place, in the sealed original container, away from excessive heat and humidity, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 5 years. The product should not be exposed to direct sunlight.

Other

- Appearance (SDS)

- Fine Powder

- Odor (SDS)

- Mild

- Mechanical Properties

Value Units Test Method / Conditions Tensile Strength 12.4 ksi ksi at Break - Physical Properties

Value Units Test Method / Conditions Density 1.2 g/cm³ g/cm³ Glass Transition Temperature (Tg) 280.0 °C °C Dynamic Mechanical Analysis (DMA) dry basis Glass Transition Temperature (Tg) 265.0 °C °C Dynamic Mechanical Analysis (DMA) wet