Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

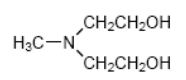

- Chemical Family

- Chemical Name

- Function

- Buffers & pH Stabilizer, Catalyst, Accelerator, Resin Modifier

- Industrial Additives Functions

- Single Ingredient

- Yes

- Synonyms

- MDEA

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Industrial Additives Features

- Labeling Claims

Applications & Uses

- Applicable Processes

- Industrial Additives End Use

- Markets

- Applications

- Application Information

The alkanolamines and their aqueous solutions will absorb carbon dioxide and hydrogen sulfide at lower temperatures and release the acid gases at higher temperatures. This forms the basis for processes which separate carbon dioxide and hydrogen sulfide from gas streams. Methyldiethanolamine is an alkanolamine used in tail gas treating and hydrogen sulfide enrichment units for selectively removing hydrogen sulfide from gas streams containing carbon dioxide. These units will, in most cases, permit 60 to 80% of the carbon dioxide to remain in the treated gas stream. Methyldiethanolamine is also used in natural gas plants for the bulk removal of carbon dioxide while producing a gas stream containing 0.25 grains hydrogen sulfide/100 scf. Bulk carbon dioxide removal can be realized with methyldiethanolamine when the CO2:H2S ratio ranges from 100 to 1,000.

Other suggested uses are urethane catalyst, textile softeners, pH control, and epoxy resin curing agents.

Properties

- Physical Form

Regulatory & Compliance

Safety & Health

- Toxicity & Safety

On the basis of acute studies with laboratory animals, methyldiethanolamine is considered slightly toxic by single oral dose and practically nontoxic by single dermal application. The oral LD50 value in the rat is 4.78 g/kg and the dermal LD50 value in the albino rabbit is 6.24 g/kg.

Methyldiethanolamine is considered moderately irritating to the eyes, but only slightly irritating to the skin. The product is not corrosive under the conditions of the DOT corrosivity test and is not regulated as a hazardous material for transportation purposes.

Because of the low vapor pressure of methyldiethanolamine, exposure to vapors is not expected to present a significant hazard under normal workplace conditions.

When handling methyldiethanolamine, chemical-type goggles must be worn. In addition, exposed employees should exercise reasonable personal cleanliness, including washing exposed skin areas several times daily with soap and water and laundering soiled work clothing at least weekly.

Should accidental contact with the eyes occur, flush them thoroughly with water for at least 15 minutes and get medical attention. Wash exposed skin areas with soap and water.

Packaging & Availability

- Regional Availability

- Availability

Methyldiethanolamine is currently available in 55-gallon drums, tank wagons, and tank cars.

Storage & Handling

- Handling & Storage Information

The handling and storage of methyldiethanolamine presents no unusual problems. See the section on toxicity and safety for related additional information.

The solvent properties and alkaline nature of methyldiethanolamine should be considered when installing handling and storage facilities. Methyldiethanolamine will react with copper to form complex salts, so the use of copper and alloys containing copper should be avoided. Carbon steel storage tanks, constructed according to a recognized code, are generally satisfactory.

Carbon steel transfer lines, at least 2 inches in diameter and joined by welds or flanges, are suitable. Screw joints are subject to failure unless back-welded because methyldiethanolamine will leach conventional pipe dopes. U.S. Rubber 899 gasket material or its equivalent is satisfactory for use with flange connections.

Centrifugal pumps are preferred with methyldiethanolamine, although carbon steel rotary pumps can be used. Rotary pumps should be equipped with externally lubricated bearings. A Durametallic Type RO-TT mechanical seal is suitable. Garlock 234, 239, or equivalent can be utilized as pump packing.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Colorless

- Odor (SDS)

- Ammoniacal