Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Base Chemicals Features

Applications & Uses

- Base Chemicals End Uses

- Markets

- Applications

- Application Information

TEROL® 250 is recommended for use in all polyurethane (PUR) and polyisocyanurate (PIR) systems, for spray, pour-in-place (PIP) and in flexible molded and flexible slabstock applications. The high aromatic content and lower viscosity of TEROL® 250 allows for the use of lower flame retardant levels with excellent viscosity and fire performance results in finished B-sides, in small scale testing.

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage and Handling

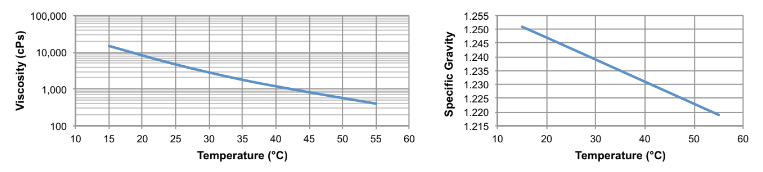

As with all industrial chemicals, care should be exercised in the handling of this material. TEROL Aromatic Polyester Polyols should be stored in tightly closed containers. Storage temperatures of 15 - 50°C are recommended for a shelf life of 6 (six) months.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Amber

- Odor (SDS)

- Odorless

- Chemical Properties

Value Units Test Method / Conditions Aromatic Content 39.5 % % Equivalent Weight 224.4 g/eq g/eq Functionality 2.0 - Hydroxyl Value 235.0-255.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Specific Gravity 1.234 - at 25°C Viscosity 4000.0-6000.0 cPs cPs At 25°C