Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Base Chemicals End Uses

- Markets

- Applications

- Application Information

- TEROL® 352 is recommended for use in all polyurethane (PUR) spray systems.

- Typically, 30-40% of the B-side can be comprised of TEROL® 352 in such applications, enhancing fire test performance, with good physical properties.

- Because of its high aromatic content, reductions in flame retardant can be realized.

- With its low viscosity and good blowing agent compatibility TEROL® 352 is a good choice when higher OH number is desired.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Technical Information

Appications :

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- As with all industrial chemicals, care should be exercised in the handling of this material.

- TEROL Aromatic Polyester Polyols should be stored in tightly closed containers.

- Storage temperatures of 15 - 50°C are recommended for a shelf life of 6 (six) months.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Amber

- Odor (SDS)

- Odorless

- Chemical Properties

Value Units Test Method / Conditions Aromatic Content 32.6 % % Equivalent Weight 160.3 g/eq g/eq Functionality 2.2 - Hydroxyl Value 335.0-365.0 mg KOH/g mg KOH/g - Physical Properties

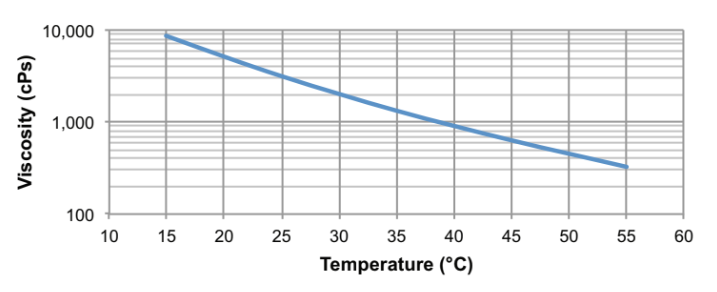

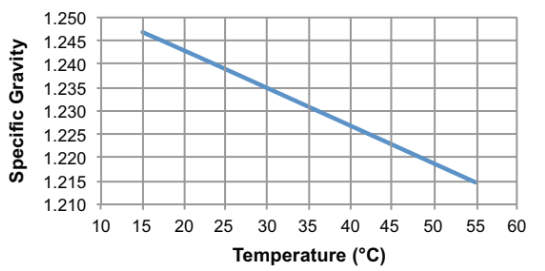

Value Units Test Method / Conditions Specific Gravity 1.239 - at 25°C Viscosity 2500.0-3500.0 cPs cPs At 25°C