Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Hardener,Accelerator,Polymerizing Agent,Adhesion Promoter

- Plastics & Elastomers Functions

- Technologies

- Product Families

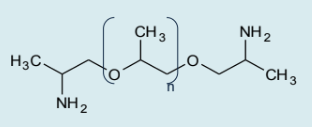

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Materials Features

- Product Features

When combined with a suitable Araldite® resin, such as GY 6010, PY 313, or GY 9513, the system offers:

- A relatively high degree of flexibility

- Good adhesion to dry concrete and sand-blasted steel

- Suitable for formulating solvent free, benzyl alcohol free, and nonyl phenol free binder systems

- The low viscosity makes it easy to handle

- Formulated polyetherpolyamine giving high level of flexibility. Elongation 110% at 23°C and up to 50% down to -10°C.

- Enables VOC free formulations

- High elongation at break

- Safer formulations with SVHC Free hardeners

Applications & Uses

- Adhesive & Sealant End Applications

- Coating End Applications

- Compatible Substrates & Surfaces

- Application Information

Flexible flooring and coating systems

- Crack-covering membranes

- To improve elongation and flexibility of brittle systems

- Flexible adhesive systems

- Solvent-free, benzyl alcohol free, and nonyl phenol free binder systems

- Nonylphenol-free. Highly flexible, even down to -10 °C. Distinctly lower viscosity than ARADUR® 75 hardener and even than ARADUR® 76 hardener. For the production of nonylphenol-free viscoplastic binder systems, impact-elastic coatings, crack-covering membranes and liquid foils for sealing purposes.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Hardeners for RT to 80°C cure

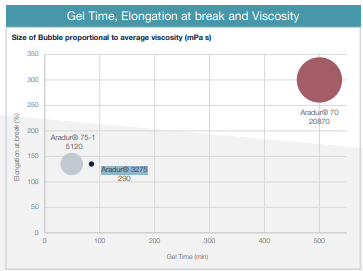

Product Latency / reactivity Impact on mechanical properties Processability: viscosity (mPa.s)

ARADUR® 3275 Good compromise between pot life and

curing time at RTHigh level of flexibility Elongation 110% at RT

and up to 50 % down to -10 °C

200 - 300 - Gel Time, Elongation at break and Viscosity

Safety & Health

- Safety Precautions

- Danger! Corrosive to eyes and skin.

- Harmful if swallowed, inhaled or absorbed through skin.

- Can cause irritation, dermatitis and sensitization.

FIRST AID: In case of contact:

- Eyes: Immediately flush eyes with water for at least 15 minutes. Get immediate medical attention.

- Skin: Immediately wash with mild soap and water.

- Ingestion: Get immediate medical attention. Do not induce vomiting. If conscious, give plenty of water to dilute.

- Inhalation: Remove to fresh air. Give oxygen if breathing is difficult.

Packaging & Availability

- Regional Availability

- Availability

ARADUR® 3275 hardener is supplied in 418 pound steel drum.

Storage & Handling

- Storage Information

product has a shelf life of two years when stored at room temperature in the original sealed container.

Other

- Appearance

- Clear, no contamination

- Color (SDS)

- Amber

- Odor (SDS)

- Amine-like

- Application Information

Value Units Test Method / Conditions Mix Ratio 129.0 g/100g g/100g GY 250 withgY 783 - Chemical Properties

Value Units Test Method / Conditions Amine Value 100.0-170.0 mg KOH/g mg KOH/g - Mechanical Properties

Value Units Test Method / Conditions Elongation 100.0 % % ASTM D412 after cure1: 7 days at 24-26°C Tear Strength 202.0 lb/in lb/in ASTM D624 after cure1: 7 days at 24-26°C Tensile Strength 1780.0 psi psi ASTM D412 after cure1: 7 days at 24-26°C - Physical Properties

Value Units Test Method / Conditions Density 1.0 g/cm³ g/cm³ At 20°C Flash Point min. 93.0 °C °C Gel Time 183.0 m m Tecam Gelation Timer at 23°C, 100g Glass Transition Temperature (Tg) max. -10.0 °C °C Cured with ARALDITE® GY 250 Viscosity 1070.0 cPs cPs ASTM D4440 at 23°C Viscosity 200.0-300.0 cPs cPs at 25°C Viscosity 1070.0 cPs cPs ICI Cone & Plate Method at 23°C