Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Polymerizing Agent,Accelerator,Curing Agent

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Materials Features

- Advantages

- High degree of flexibility, even at temperatures as low as - 10°C

- Good adhesion to dry concrete and sand-blasted steel

- Product Benefits

- Enables VOC free crack bridging formulations

- High elongation at break

- Excellent adhesion

- Safer formulations with SVHC Free hardeners

- High degree of flexibility, even at temperatures as low as - 10°C

- Good adhesion to dry concrete and sand-blasted steel

Applications & Uses

- Adhesive & Sealant End Applications

- Coating End Applications

- Compatible Substrates & Surfaces

- Composites End Use

- Markets

- Applications

- Application Information

- Non-porous, crack-bridging membranes

- Flexible high performance coatings in civil engineering

- Elastic adhesive systems

- Flexible epoxy castings or pottings

- Flexible base-coats for tank linings

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

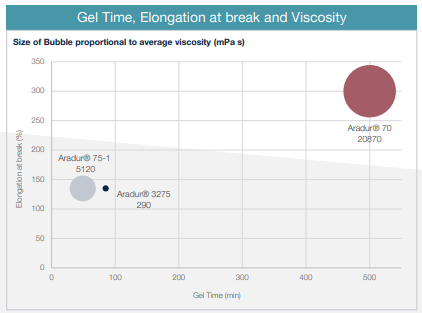

- Gel Time, Elongation at break and Viscosity Graph

Safety & Health

- First Aid

In case of contact:

- Eyes: Immediately flush with water for at least 15 minutes. Get immediate medical attention.

- Skin: Promptly wash thoroughly with mild soap and water.

- Inhalation: Remove to fresh air. Give oxygen if breathing is difficult.

- Ingestion: If conscious, give plenty of water. Get immediate medical attention.

Packaging & Availability

- Regional Availability

- Packaging

ARADUR® 70 is supplied in 418 pound steel drums.

Storage & Handling

- Storage Information

This material should be stored at room temperature in the original sealed container .

- Safety Precautions

Warning! Can cause severe eye and skin irritation, and allergic skin reactions. May cause central nervous system depression

- Do not get in eyes, on skin or clothing.

- Do not inhale mist or vapors.

- Keep container tightly closed when not in use and during transport.

- Wash after handling.

Other

- Appearance

- Hazy, no contamination

- Application Information

Value Units Test Method / Conditions Mix Ratio 400.0 phr phr With Araldite® GY 6010 Liquid Epoxy Resin - Chemical Properties

Value Units Test Method / Conditions Amine Value 65.0-75.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Density 1.02 g/cm³ g/cm³ At 25°C Flash Point 103.0 °C °C Closed Cup Gel Time 300.0-500.0 m m at 23°C, with ARALDITE® GY 250, 100g Glass Transition Temperature (Tg) max. -10.0 °C °C Cured with ARALDITE® GY 250 Viscosity 17000.0-27000.0 mPa.s mPa.s At 25°C