Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Very low density two-part epoxy syntactic

- Room temperature cure

- Non sagging

Applications & Uses

- Application Area

- Markets

- Applications

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

Mix ratio Parts by weight Parts by volume Araldite®1644 A 100 100 Araldite®1644 B 20 16.3 Application

The resin and hardener must be blended until they form a homogeneous mix, shown by a uniform pale green colour. The mix can be applied manually or extruded. Any material not used within 30 minutes of mixing should be pumped or spread out thinly on a disposable surface and allowed to cure to eliminate the risk of exotherm.

Equipment maintenance

All tools should be cleaned before syntactic residues have had time to cure. Theremoval of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, the operator should take the appropriate precautions and avoid skin and eye contact.

Recommended cure schedule

24 - 36 hours at 23°C or 3 - 4 hours at 23°C + 2 hours at 60 - 80⁰C

Properties

- Physical Form

Regulatory & Compliance

- OEM Specifications

Technical Details & Test Data

- Typical Cured Information

DRY compression properties

Property Test Temp (°C) Results (MPa) Compressive Strength -55 35 - 50 23 25 - 35 80 15 - 20 Compressive Modulus -55 1100 - 1400 23 1000 - 1300 80 400 - 700 Tested per ISO 604, cure cycle: 3 - 4 hours at 23°C + 2 hours at 60°C

WET compression properties after 2000 hours 85%RH/70°C

Property Test Temp (°C) Results (MPa) Compressive Strength 23 21 - 24 80 3.1 – 3.4 Compressive Modulus 23 1000 - 1200 80 100 - 110 Tested per ISO 604, cure cycle: 3 - 4 hours at 23°C + 2 hours at 60°C

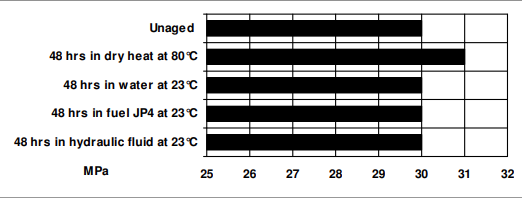

Compressive strength at 23°C versus immersion in various media (typical average values)

Tested per ISO 604, cure cycle: 3 - 4 hours at 23°C + 2 hours at 60°C

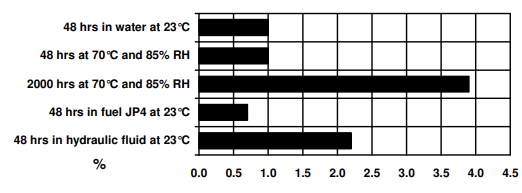

Fluid absorption in various media (typical average values)

Glass transition temperature (typical values)

Curing cycle Tg onset TMA (°C) Tg DSC (°C) 24 hrs at 23°C 55 - 60 3-4 hrs at 23°C + 2 hrs at 60°C 80 - 90 3-4 hrs at 23°C + 2 hrs at 80°C 90 - 100

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Handling Information

- Araldite® 1644 A/B must be stored at 2 - 8°C for at least 12 months and the components must be stored in their original sealed containers. The expiry date is indicated on the label.

- These products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Other

- Color

- Pale green

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.2 - Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Density 0.5-0.6 g/cm³ g/cm³ ISO 1183