Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Two component epoxy adhesive

- Cold cured system

- Can be used in conjunction with riveting

- Good strength retention up to 120°C

Applications & Uses

- Application Area

- Markets

- Applications

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

Mix ratio Parts by weight Parts by volume Araldite®403 A 100 - Araldite®403 B 7.5 - The resin and hardener should be blended until they form a homogeneous mix

Pot life

To obtain the maximum workable life after mixing, pour the adhesive into a shallow tray to a maximum depth of about 6mm. This will assist rapid dissipation of heat generation

by exothermic reaction.The workable life will then be approximately 11⁄2 hours at 25°C. This will be reduced at higher temperatures, or may be increased by maintaining a lower temperature.Application of adhesive

Araldite® 403 may be applied by extrusion or by spreading with a roller or serrated comb spreader. Apply a thin coating of the adhesive to each surface of the joint; for honeycomb-to-skin bonds apply the adhesive to the honeycomb surface and to the skins.

Assembly

The joint assembly must be completed and securely clamped or tack riveted within 2 hours of mixing the adhesive. Araldite® 403 has excellent gap-filling properties and is tolerant of glue-line thickness variations over the range 0.08 - 0.80mm.

Riveting

Araldite® 403 does not appear to be sensitive to riveting operations, but there is a risk that the joint may be disturbed if the assembly is moved during the most critical part of

the adhesive curing period. All riveting should be done before the adhesive has set or after it has hardened sufficiently to withstand normal handling. Unless the assembly is rigidly clamped in a jig to prevent movement, riveting should not be done during the 6 hours immediately following adhesive application; alternatively, the assembly should be left undisturbed for at least 24 hours after clamping or tack riveting before further work is carried out on it.Equipment maintenance

All tools should be cleaned before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Curing

At 22°C Araldite® 403 will attain 50% of its ultimate strength approximately 2 days after mixing, 80-90% of its full strength after 1 week, and full strength after about 8 weeks.Where circumstances permit, curing time can be reduced to 16 hours by warming the assembly to 45 ± 5°C.

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

Technical Details & Test Data

- Typical Cured Information

The following data has been obtained for Araldite®403 on tensile lap shear standard specimens made by lap-jointing (102 x 25 x 1.6) mm strips of aluminium alloy. The joint area was (12.5 x 25) mm in each case.

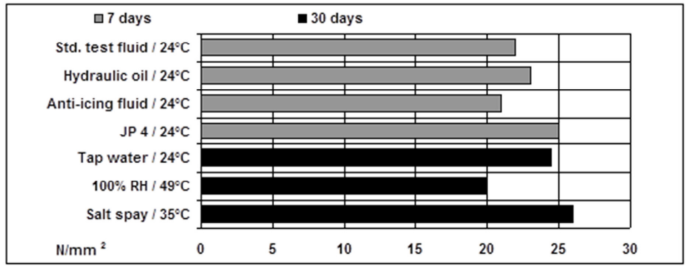

Tensile shear strength: effect on fluid immersions (Typical average values)

Cure: 42 days at 22°C

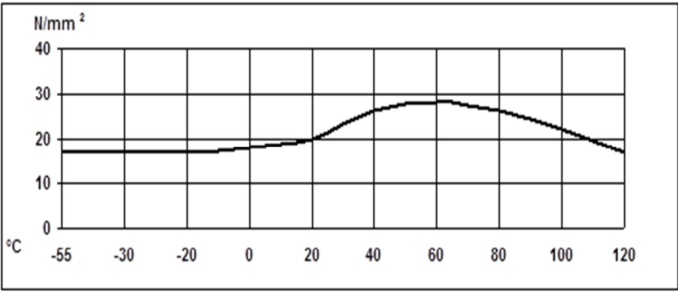

Lap shear strength versus temperature (ISO 4587) (typical average values)

Cure: 42 days at 22°C

Safety & Health

- Safety Information

These products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Storage & Handling

- Storage Conditions

Araldite® 403 A/B may be stored at 25-40°C, provided the components are stored in their original sealed containers. The expiry date is indicated on the label. Due to the chemical formulation of the Araldite® 403 A itself, it can happen from time to time that some small lumps appear in the product over time. These lumps are known to be recrystallized semi-solid epoxy resin particles.This recrystallization issue occurs randomly but can usually be minimized by avoiding cold storage conditions (below room temperature).In case of recrystallization, the lumps can be melt again, without affecting the properties on the product, using the following method :

- Open the cans of Araldite® 403 A & heat them up at 60°C in an oven for at least 1 hour to allow the viscosity to go down.

- Using a disperser, stir the heated resin at 500 t/min for 2 to 3 hours (maintaining the heat during the stirring operation will help).Stirring under vacuum will also avoid bubbles.

- Check regularly the aspect of the product till it is lumps free.

- Let the product cool down, then close the lid & store the cans at room temperature.

Other

- Color

- Grey

- Physical Properties

Value Units Test Method / Conditions Lap Shear Strength min. 17.9 MPa MPa Internal Method at 23°C Specific Gravity 1.5-1.6 - Viscosity approx. 150.0 Pa.s Pa.s Internal Method at 25°C - Application Information

Value Units Test Method / Conditions Mix Ratio 0.075 %(W) %(W) Hardener : Resin