Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Properties

- Good mechanical strength.

- High temperature resistance up to 120°C.

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Markets

- Applications

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependent on proper pretreatment of the surfaces to be bonded. At a minimum, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline or paint thinners should never be used. The strongest and most durable joints are obtained after either mechanically abrading or chemically etching the degreased surfaces.

All machining and preparation of the repair surfaces should be completed before ARALDITE® 501 A/B is prepared for use. Surfaces must be clean, dry and free from grease or loose deposits, and should have a uniform, finely roughened (matte) finish. This will enable the resin to wet the surface properly, thus creating a high strength bond.

Mechanical processing

Special equipment has been developed to meter, mix and dispense bulk adhesives. Huntsman will be pleased to advise customers on the choice of equipment that will meet their particular needs.

Equipment maintenance

All tools should be cleaned with hot water and soap before adhesive residues have had time to cure. The removal of cured residues is a difficult and time- consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions as described in the applicable MSDS.

Typical Cure Schedules

At 77°F (25°C), ARALDITE® 501 A/B epoxy adhesive achieves 50% of its full strength approximately two days after mixing, 80 - 90% after seven days and full strength after seven weeks. Where circumstances permit, curing time can be reduced by warming the repair assembly:

- At 113°F (45°C), ARALDITE® 501 A/B epoxy adhesive will cure fully in 16 hours.

- At 158°F (70°C), ARALDITE® 501 A/B epoxy adhesive will cure fully in two hours.

- Application Information

- Impregnate the dry repair fabric with mixed ARALDITE® 501 A/B epoxy adhesive using a brush or spreader bar on a release-covered surface.

- Cut layers of the wet fabric to shape and position on the prepared, damaged area.

- After consolidating with a roller, cover the assembly with a vacuum bag lay-up and apply vacuum throughout the cure cycle.

- A heater mat placed between the release film and breather layer will reduce cure time.

- If the honeycomb is exposed in the damaged area, it should first be filled with one of Huntsman Advanced Materials' syntactic filler pastes, and cured before application of ARALDITE® 501 A/B epoxy adhesive and fabric.

- Application Of Adhesives

Application of Adhesive:

Impregnate the dry repair fabric with mixed ARALDITE® 501 A/B epoxy adhesive using a brush or spreader bar on a release-covered surface. Cut layers of the wet fabric to shape and position on the prepared, damaged area. After consolidating with a roller, cover the assembly with a vacuum bag lay-up and apply vacuum throughout the cure cycle. A heater mat placed between the release film and breather layer will reduce cure time. If the honeycomb is exposed in the damaged area, it should first be filled with one of Huntsman Advanced Materials' syntactic filler pastes, and cured before application of ARALDITE® 501 A/B epoxy adhesive and fabric.

Properties

- Notes

¹ - Tests were conducted using 8 harness satin weave glass fabric, No. 181, with P-703 finish, and were carried out on specimens cut from laminates cured for 3 hours at 66°C.

Regulatory & Compliance

Technical Details & Test Data

- Technical Information

Pretreatment

- The strength and durability of a bonded joint are dependent on proper pretreatment of the surfaces to be bonded.

- At a minimum, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline or paint thinners should never be used.

- The strongest and most durable joints are obtained after either mechanically abrading or chemically etching the degreased surfaces.

- All machining and preparation of the repair surfaces should be completed before ARALDITE® 501A/B is prepared for use.

- Surfaces must be clean, dry and free from grease or loose deposits, and should have a uniform, finely roughened (matte) finish.

- This will enable the resin to wet the surface properly, thus creating a high strength bond.

Mechanical processing

- Special equipment has been developed to meter, mix and dispense bulk adhesives.

- Huntsman will be pleased to advise customers on the choice of equipment that will meet their particular needs.

Equipment maintenance

- All tools should be cleaned with hot water and soap before adhesive residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

Typical Cure Schedules

- At 25°C ARALDITE® 501 A/B epoxy adhesive achieves 50% of its full strength approximately two days after mixing, 80 - 90% after seven days and full strength after seven weeks.

- Where circumstances permit, curing time can be reduced by warming the repair assembly:

- At 45°C ARALDITE 501 A/B epoxy adhesive will cure fully in 16 hours.

- At 70°C ARALDITE501 A/B epoxy adhesive will cure fully in two hours.

- Cured Properties

Typical Cured Properties:

The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification. The following tests were conducted using 8 harness satin weave glass fabric, No. 181, with P-703 finish, and were carried out on specimens cut from laminates cured for 3 hours at 150°F (66°C).

Property Dry at 73°F (23°C) Wet at 73°F (23°C) Dry at 158°F (70°C)

Flexural Strength, ASTM D-790, psi (MPa) 76,850 (530) 43,500 (300) 58,000 (400) Flexural Modulus, ASTM D-790, ksi (GPa) 3,190 (22) 2,465 (17) 2,610 (18) Tensile Strength, ASTM D-638, psi (MPa)* 46,400 (320) 29,000 (200) 40,600 (280) Tensile Modulus, ASTM D-638, ksi (GPa)* 2,900 (20) 2,900 (20) 2,755 (19) Flexural Modulus on unreinforced material, ASTM D-790, ksi (GPa) 507.5 (3.5) -- -- Tensile Strength on unreinforced material, ASTM D-638, psi (MPa)* 11,600 (80) -- -- * Using ISO 527 type 1 specimens.

Cure Tg (°F (°C)) 3 days at 77°F (25°C) 246 (119) 7 days at 77°F (25°C) 253 (123) 2 hours at 158°F (70°C) 250 (121) Typical Tg values of ARALDITE® 501 A/B epoxy adhesive determined by DMTA.

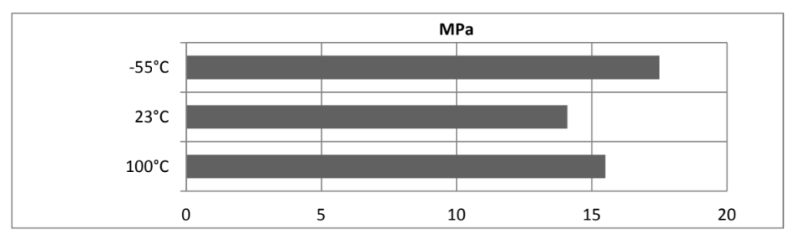

- Lap Shear Strengths of Typical Metal-to-metal Joints

Average lap shear strengths of typical metal-to-metal joints (ISO 4587) (typical average values)

- Cured for 2 hours at 70°C and tested at indicated temperatures.

- Aluminium Pretreatment - Degreasing and chromic acid pickling.

- Testing of standard specimens made by lap-jointing (114 x 25 x 1.6) mm strips of aluminium alloy.

- The joint area was 12.5 x 25 mm in each case.

Packaging & Availability

Storage & Handling

- Storage Conditions

ARALDITE® 501 A/B epoxy adhesive should be stored in a dry place, in the sealed original container, at temperatures between +18°C and +40°C (+64.4°F and 104°F). Under these storage conditions, the shelf life is 2 years. The product should not be exposed to direct sunlight. Material temperatures should be above 18°C (+64.4°F) when mixing. After use, tightly reseal containers.

- Storage Information

Storage

- ARALDITE® 501 A/B components must be stored in their original, sealed containers at (2-40) °C.

- Material temperatures should be above 18°C when mixing.

Handling

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin.

- Adequate ventilation of the working area is recommended.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.15 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity 1.1-1.2 - ASTM D792 Viscosity 3500.0 cPs cPs ASTM D2393 at 23°C