Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Easy handling combined with long pot-life at moderate temperature

- Short gel and demolding time at temperature above 140°C

- High tracking and arc resistance

- Very high erosion resistivity under ultraviolet radiation

- Good dielectric properties

- Insulating material with excellent outdoor behavior

- Features and Benefits

- Easy handling combined with long pot-life at moderate temperature

- Short gel and demolding time at temperature above 140°C

- High tracking and arc resistance

- Very high erosion resistivity under ultraviolet radiation

- Good dielectric properties

- Insulating material with excellent outdoor behavior

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Application Information

- Outdoor electrical insulating components

- Bushings

- Line post and pin insulators in the medium voltage range

- All components for humid indoor medium and high voltage environments

- Application Details

- Outdoor electrical insulating components

- Bushings

- Line post and pin insulators in the medium voltage range

- All components for humid indoor medium and high voltage environments

Technical Details & Test Data

- Cured Properties

Key Value Unit Test Method Test Condition Tensile strength 12,300 - 13,800 psi ASTM D638 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Tensile modulus 1.43 - 1.49 × 10⁶ psi ASTM D638 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Elongation at break 1.20 - 1.60 % ASTM D638 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Flexural strength 17,400 - 18,800 psi ASTM D790 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Flexural modulus 1.43 - 1.49 × 10⁶ psi ASTM D790 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Surface strain 1.1 - 1.5 % -- at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Critical stress intensity factor (Kic) 2.1 - 2.3 MPa·m¹/² DSC at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Specific energy at break (Gic) 400 - 490 J/m² DSC at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Glass transition temperature 95 - 105 °C DSC at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Coefficient of thermal expansion 30 - 35 × 10⁻⁶ ppm/°C TMA at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Water absorption (specimen: 50 x 50 x 4mm) 0.14 - 0.18 % by wt. ASTM D570 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Thermal conductivity 0.70 - 0.90 W/m·K ISO 8894-2/90 at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Density at 25°C 1.7 g/cm³ -- at 23°C, cured for 2 h at 100°C + 2 h at 150°C

Inclined Plane Tracking and Erosion Test > 2000 min -- at 2.5 kV Inclined Plane Tracking and Erosion Test > 300 min -- at 3.5 kV HV arc resistance 195 - 210 sec -- at 23°C, cured for 2 h at 100°C + 2 h at 150°C

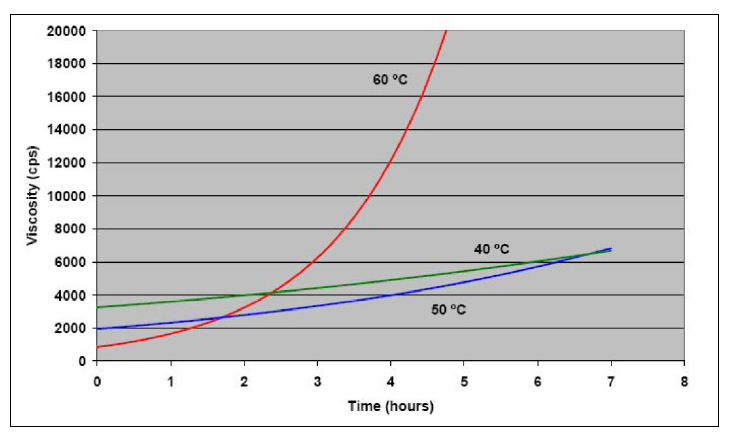

Figure 1. Viscosity as a function of time for CW 5817 / HY 1235 / DY 062

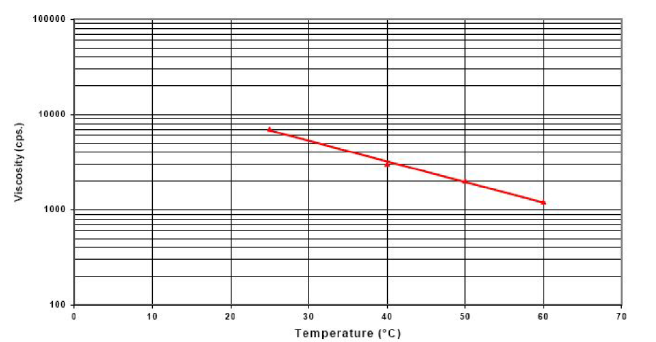

Figure 2. Mixed viscosity as a function of temperature for CW 5817 / HY 1235 / DY 062 system

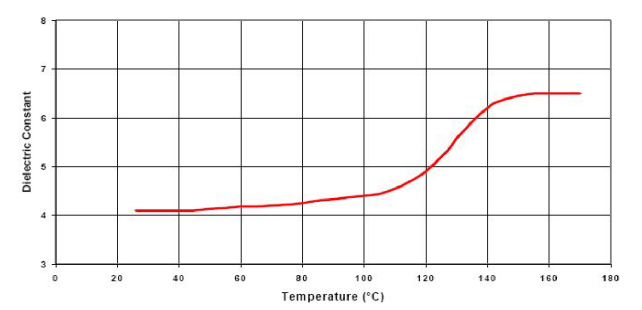

Figure 3. Dielectric constant as a function of temperature at 60Hz

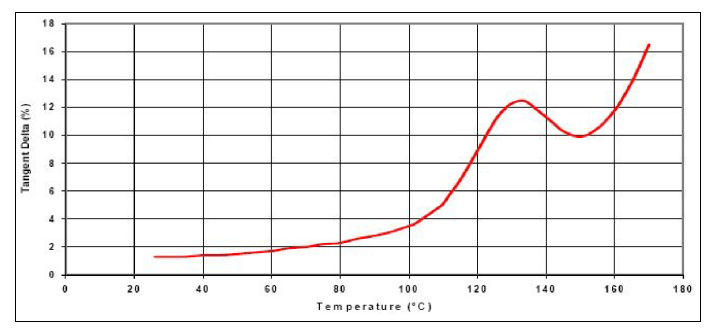

Figure 4. Dissipation factor as a function of temperature

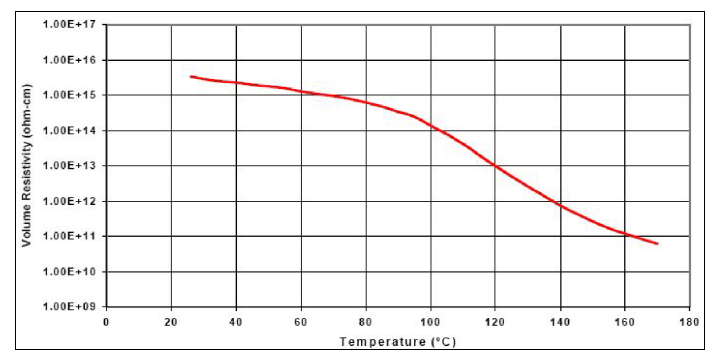

Figure 5. Volume resistivity as a function of temperature

- Processing Data

ARALDITE® CW 5817 resin should be heated in its original container to 50°C or 60°C in an oven. Pre-weigh the appropriate amount of resin component into a mixing vessel. According to the mixing ratio below, add the correct amount of ARADUR® HY 1235 hardener (at room temperature) followed by the correct amount of ACCELERATOR DY 062 (also at room temperature). The three components should then be mixed under a vacuum of 4 - 8 mbar at slight elevated temperature. The recommended mix temperature is 40 °C - 50 °C. Depending on the quantity mixed, mixer device, mixing temperature and application, the recommended mixing time is 0.25 to 1 hour. The effective pot-life of the mixed system is about 1 to 2 days at temperatures below 25 °C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations must be

cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a weekend without cleaning are possible if the pipes are cooled at temperatures below 10 °C. For information regarding viscosity increase and gel time at various temperatures,- Processing Guidelines

Araldite® CW 5817 resin should be heated in its original container to 50°C or 60°C in an oven. Pre-weigh the appropriate amount of resin component into a mixing vessel. According to the mixing ratio below, add the correct amount of Aradur® HY 1235 hardener (at room temperature) followed by the correct amount of Accelerator DY 062 (also at room temperature). The three components should then be mixed under a vacuum of 4 - 8 mbar at slight elevated temperature. The recommended mix temperature is 40 °C - 50 °C. Depending on the quantity mixed, mixer device, mixing temperature and application, the recommended mixing time is 0.25 to 1 hour. The effective pot-life of the mixed system is about 1 to 2 days at temperatures below 25 °C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations must be cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a weekend without cleaning are possible if the pipes are cooled at temperatures below 10 °C. For information regarding viscosity increase and gel time at various temperatures, refer to Figure 1.

Parameter APG process Convention vacuum casting

Mold temperature 130 - 160°C 80 - 100°C Demolding times (depending on mold temperature and casting volume) 8 - 40 minutes 4 - 8 hours Cure conditions 2 h at 150°C or 5 h at 140°C 2 h at 150 °C or 5 h at 140 °C

To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and post-curing cycles in the manufacturing process could influence the crosslinking and the glass transition temperature respectively.

Safety & Health

- Safety Precautions

Huntsman Advanced Materials Americas LLC maintains up-to-date Safety Data Sheets (SDS) on all of its products. These sheets contain pertinent information that you may need to protect your employees and customers against any known health or safety hazards associated with our products. Users should review the latest MSDS to determine possible health hazards and appropriate precautions to implement prior to using this material.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Conditions

- Araldite® CW 5817 Resin contains cure-accelerating additives. It should not be stored for long periods at temperatures in excess of 30°C (86°F), nor should it be exposed to temperatures in excess of 100°C (212°F) for more than 2 hours. Incorrect handling will result in an increase in viscosity and reduced cured-state properties.

- Aradur® HY 1235 Hardener is moisture sensitive. Partially used containers should be closed immediately after use. Nitrogen blanketing is highly recommended as well as the use of a desiccant venting device unless the material is going to be used rapidly after opening. For Accelerator DY 062, if only part of container is used, re-close to prevent contamination.

- Araldite® CW 5817 US / HY 1255 / DY 062 system should be stored in a dry place, in the sealed original container, between 2°C and 40°C Under these storage conditions, the shelf life is 1 year (from date of manufacture). The products should not be exposed to direct sunlight. As with most pre-filled systems, the fillers present in these components have a tendency to separate during storage. This filler separation will not negatively affect the final product properties and quality provided that both components are thoroughly homogenized. The filled components should be stirred carefully by using a low shear mixer prior to processing. Do not use high speed or high shear mixers and take precautions to prevent air entrapment.

- Storage Information

- ARALDITE® CW 5817 Resin contains cure-accelerating additives. It should not be stored for long periods at temperatures in excess of 30°C (86°F), nor should it be exposed to temperatures in excess of 100°C (212°F) for more than 2 hours. Incorrect handling will result in an increase in viscosity and reduced cured-state properties.

- ARADUR® HY 1235 Hardener is moisture sensitive. Partially used containers should be closed immediately after use. Nitrogen blanketing is highly recommended as well as the use of a desiccant venting device unless the material is going to be used rapidly after opening. For ACCELERATOR DY 062, if only part of container is used, re-close to prevent contamination.

- ARALDITE® CW 5817 US / HY 1255 / DY 062 system should be stored in a dry place, in the sealed original container, between 2°C and 40°C Under these storage conditions, the shelf life is 1 year (from date of manufacture). The products should not be exposed to direct sunlight. As with most pre-filled systems, the fillers present in these components have a tendency to separate during storage. This filler separation will not negatively affect the final product properties and quality provided that both components are thoroughly homogenized. The filled components should be stirred carefully by using a low shear mixer prior to processing. Do not use high speed or high shear mixers and take precautions to prevent air entrapment.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.00125 %(W) Accelerator : Resin Mix Ratio 0.23 %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Glass Transition Temperature (Tg) 95.0-105.0 °C Viscosity 3800.0 cPs at 40°C