Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Very good mechanical and electrical properties

- Good resistance to thermal shock

- Good dielectric properties under humid conditions

- Resistant to corrosion caused by UV radiation Suitable for manufacturing Good weather resistance and harsh operating conditions

- Insulators and transformers

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- System Preparation

Basics of working with liquid resin systems

Araldite® resin and Aradur® curing agent are recommended to be preheated at the following temperatures: ARALDITE resin: 50°C preheating for 6 - 12 hours ARADUR curing agent: room temperature. Mix all components thoroughly under vacuum. (The mixing temperature can reach about 60°C If a lower mixture viscosity is desired, the resin may be preheated at a higher temperature, but not exceeding 80°C )

The right mix will result in:

- Better flow and less shrinkage tendency

- Lower internal stress and thus improved mechanical strength of the product

- Improving partial discharge performance in high voltage equipment

For medium to high viscosity Araldite casting resin systems at low mixing temperatures, we recommend Other thin film degassing mixing equipment may generate additional self-heating of 10-15°C due to friction. For Araldite® casting resin systems of low viscosity, a conventional anchor mixer is sufficient. In larger plants, two premix tanks are used to mix the resin and hardener and their corresponding amounts of filler separately under vacuum. The premix is mixed with the auxiliary materials, and then the metering pump supplies the premix to the final mixing tank or continuous mixing equipment. The mixture can be stored at a higher temperature (approximately 60°C) for up to 1 week, depending on the specific materials. Stir appropriately during the process to prevent the filler from settling. The mixing time depends on the mixing temperature, quantity, mixing equipment and specific application, and can be from 0.5 to 3 hours . The required vacuum is 0.5 to 8 mbar. The vapor pressures of the individual components must be taken into account.

- Applications

Outdoor medium and high voltage electrical insulation components, such as current and voltage transformers.

Technical Details & Test Data

- Gelation / Cure Time

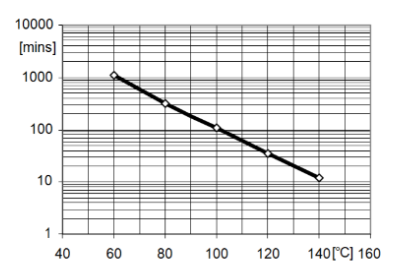

Figure 4.2: Gel time as a function of temperature (measured using a Gelnorm instrument according to DIN 16945/6.3.1)

- Process Viscosity

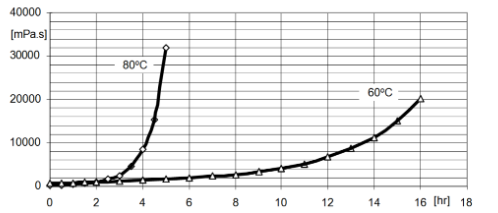

Fig.4.1: Viscosity increase at 60 and 80°C (measured with Brookfield instrument)

- Specific Instructions

Dilute remaining mix with resin before overnight or weekend storage and balance with another component before resuming work. Pipes containing premix or castables should be cooled immediately after work to prevent filler settling and/or undesirable viscosity increase. This helps to reduce material loss and saves cleanup work.

For gel time at various temperatures, refer to Figures 4.1 and 4.2. .

Mold temperature

APG process 130 - 160°C

Conventional vacuum casting 70 - 100°C

Demolding time (depending on mold temperature and casting volume)

APG process : 10 - 40 min

Conventional vacuum casting : 5 - 8h

Curing conditions

APG process (minimum curing time) : 4h at 130°C or 3h at 140°C

Conventional vacuum casting : 12h at 130°C or 8h at 140°C

To determine whether the crosslinking is complete and whether the final performance is optimal, it is necessary to conduct relevant tests on the actual cured product or measure the glass transition temperature. Different gels and curing procedures during the manufacturing process can lead to different crosslinking degrees and glass transition temperatures.

- Electrical Properties

Measured by standard specimen at 23°C The specimen was cured at 80°C for 6h and 130°C for 8h

Property

Test Method

Unit

Value

Breakdown Strength

IEC 243-1

kV/mm

18–20

Tracking Resistance

IEC 112

CTI

>600M–0.0

Resistivity

DIN 53489

Class

A1

- Mechanical & Physical Properties

Measured by standard specimen at 23°C The specimen was cured at 80°C for 6h and 130°C for 8h

Property

Test Method

Unit

Value

Tensile Strength

ISO R 527

N/mm²

70

Tensile Elongation

ISO R 527

%

1

Breaking Strength

ISO R 527

N/mm²

10500

Flexural Strength

ISO 178

MPa

125

Surface Hardness

ISO 178

%

1.6

Flexural Modulus

ISO 178

MPa

9900

Shear Modulus

PM 216/89

MPa·m²

2.5

Glass Transition Temperature

ISO 11357-2

°C

73–88

Water Absorption

ISO 62

% by wt.

0.1–0.2

Density

DIN 55990

g/cm³

1.82

Hardness

DIN 53505

Shore D

90

Shrinkage

ISO 294-4

%

0.85

Safety & Health

- First Aid

When eyes come into contact with resin, hardener or castable, flush immediately with clean, running water for 10 to 15 minutes. See a doctor. Material that comes into contact with or splashes on skin should be wiped off and then the affected area should be washed with running water. In case of severe pain or burns, see a doctor. Change soiled clothing immediately. If discomfort occurs due to inhalation of vapors, go outdoors immediately. If in doubt, seek medical help.

- Industrial Hygiene

Mandatory and recommended industrial hygiene procedures should be followed when- ever our products are being handled and processed.

Storage & Handling

- Storage Conditions

Liquid resin premixes always have some filler settling. If only a portion is used, it is recommended to Stir well. It is best to use the whole bucket.

ARALDITE CW 5837 CI should be stored in a dry environment at 2 - 40°C in a tightly sealed container.

ARADUR HY 5877 CI should be stored in a dry environment at 5 - 25°C . In tightly sealed original container.

Under these conditions, the storage period corresponds to the expiration date indicated on the packaging label. After this date, The product must be tested to determine whether it is still effective. If it is a part, it should be sealed and tightened immediately.