Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

The product offers high thermal shock resistance combined with high glass transition temperature (Tg), very good electrical and mechanical proprieties.

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Processing Information

Araldite® CW 5938 Resin and Aradur® HY 5939 Hardener system is ideally suited for processing by conventional techniques. The optimum gelation and cure schedule in this case is dependent on the part design.

General instructions for preparing prefilled resin systems

Araldite® CW 5938 Resin and Aradur® HY 5939 Hardener contain fillers which tend to settle over time. It is therefore necessary to carefully homogenize the complete contents of the container before use. To prevent filler separation and inconsistent metering, the components should be gently stirred from time to time while they are present in the production equipment storage tanks.

Mixing

To facilitate stirring and handling, highly filled components should be heated to 50 - 60°C in their original container (e.g. overnight in an oven). After a thorough mixing, each component should be maintained at 50 - 60°C in the production equipment under a 1 - 5 mbar vacuum.

The two components should be mixed in the appropriate ratio under vacuum and at temperatures 50 to 60°C. The use of a thin film degassing mixers is recommended for medium to high viscous casting resin systems or for mixing at lower temperatures. This type of equipment can typically cause a 10 to 15 oC rise in temperature due to friction. Depending on quantity, mixer type, mixing temperature and application, the mixing time is typically about 0.5 - 1.5 hours under a 1 to 8 mbar vacuum.

In automatic mixing and metering installations, both components will be degassed and homogenized under a vacuum of about 2 mbar in the holding tanks. When degassed, the prefilled products are stirred up from time to time to avoid any sedimentation. Typically, after dosing and mixing with a static mixer, the resin system is fed directly to the vacuum chamber or, in the automatic pressure gelation process, directly into the hot casting mold. By using circular feeding tubes, several casting stations can be served.

Properties

- Physical Form

Technical Details & Test Data

- Electrical Properties

Electrical data was collected on standard specimen at 23°C (73°F). The specimens are cured at 80°C for 10 hours + 140°C for 10 hours.

Property

Test Method

Value

Dielectric Breakdown, (KV/mm)

IEC 243-1

20 - 23

Arc Resistance HV, (s)

ASTM D 495

186 - 198

Resistance to Tracking, Test A Solution

Resistance to Tracking, Test B SolutionIEC 112

IEC 112> 600 - 0.0

> 600M - 0.0Electrolytic Corrosion

DIN 53489

A-1

- Specific Instructions

Specific Instructions

The effective pot-life of the mix is about 2 to 3 days at temperatures below 25°C. Conventional batch mixers should be cleaned once a week or at the end of the shift. For longer work interruptions, the pipes of the mixing and metering equipment should be cooled and cleaned with the resin to prevent sedimentation and/or undesired viscosity increase. Interruptions over a week-end (approx. 48 hours) without cleaning may be possible if the lines are cooled at temperatures below 18°C.

Process condition Conventional Vacuum Casting APG Process Molding temperature 70°C-100°C 130°C-160°C Demolding time (Depends on the temperature and

volume of the casting mold)4 - 8 hours 10 - 40 minutes Curing cycle 8 hours at 130°C 4 hours at 140°C Product Parts by weight

Araldite® CW 5938 Resin : 100

Aradur® HW 5939 Hardener : 100

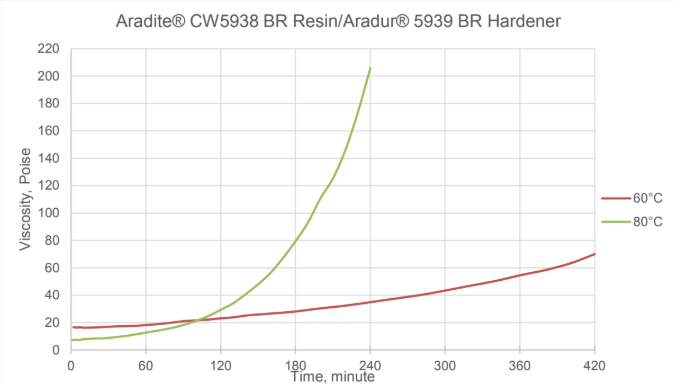

The mixed density of the resin and the hardener at 25°C is about 1.75 g/cm3 (used ISO 2811).Figure 1. Viscosity at 60 °C and 80 °C (Measured with AR2000 - shear rate 10/s)

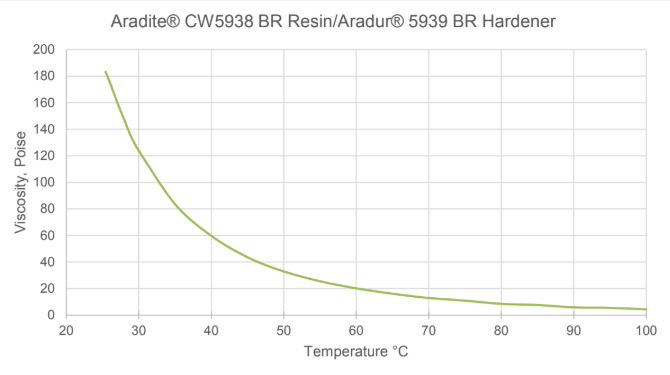

Figure 2. Viscosity versus temperature (Measured with AR2000 - shear rate 10/s, 2°C/min.)

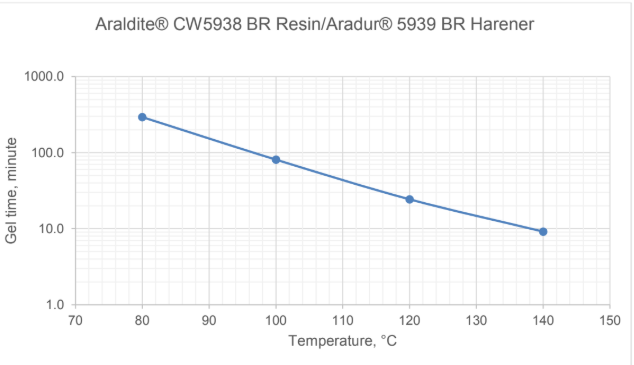

Figure 3. Gel time versus temperature (Measured with Sunshine Gel Timer, 10 grams- AMTM 0046)

Safety & Health

- Precautions

To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out some relevant measurements on the actual part or to measure the glass transition temperature or the hardness (Shore A / D) of the cured system. Different gel and cure cycles in the manufacturing process are likely to lead to a different degree of crosslinking, hence different glass transition temperatures and hardness.

Storage & Handling

- Storage Conditions

Araldite® CW 5938 Resin and Aradur® HW 5939 Hardener should be stored in a dry place, in its sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 12 months from the date of manufacture. The product should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin