Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Bonds well to ABS and other thermoplastic housing materials

- Excellent sulfuric acid resistance

- Low viscosity

- Convenient 2 to 1 mix ratio by volume

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

Potting, sealing and encapsulation applications requiring sulfuric acid resistance, e.g. terminal potting of lead acid batteries.

Properties

- Physical Form

Technical Details & Test Data

- System Preparation

Mix the two component with a meter-mix dispensing equipment or manually as follows:

Weigh the desired amount of resin into a mixing container, add the corresponding amount of hardener to the resin. Mix thoroughly by means of mechanical mixer or manually. Be sure to scrape the sides and walls of the mixing container during mixing. Check for uniform color as a sign of complete mixing. A minimum of one minute mixing time is being suggested - three to five minutes mixing time is optimal.

For potting or encapsulating applications, dispense or pour directly into the area to be filled. To minimize air bubbles, de-gas under vacuum prior to potting and pour the material into the area to be filled (preferably at the lowest point). Do not move the stream of liquid back and forth as this may entrap air. Allow the material to slowly flow around and through the subcomponents to be encapsulated. Keep the stream of material thin and continuous to assist in breaking any bubbles which may be present and to prevent the introduction of additional air.

- Processing Information

Typical Cured Properties

Key Value Unit Test Method Hardness, Shore D 80 - 90 Shore D ASTM D-2240 Thermal Conductivity 0.263 W/m-K ASTM E-1225 Arc resistance 67 seconds ASTM D-495 Track Resistance (Initial tracking voltage, 3.5 kV)

1.3 minutes IEC 60587 Track Resistance (Time to track @ 2.50 kV) 10.8 minutes IEC 60587 Dielectric Strength 700 Volt/mil IEC 60243-1 Tg (DSC) 60 - 80 °C DSC Lap shear strength at break > 1,200 psi ASTM D-1002 Peak Exotherm Temperature 176 °C DSC Average weight gain 1.02 wt. % N/A

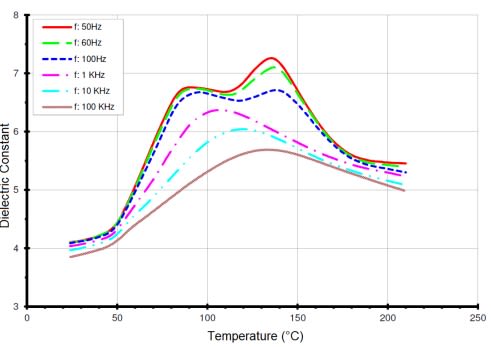

Figure 1 - Dielectric Constant

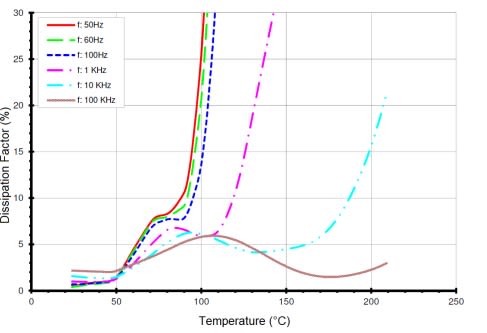

Figure 2 - Dissipation Factor

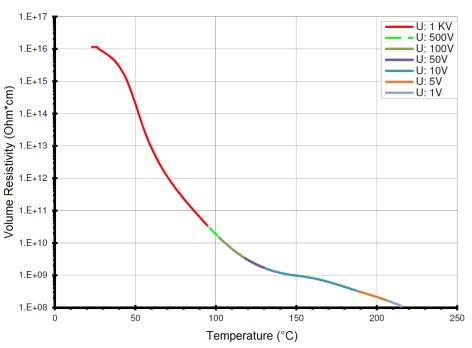

Figure 3 - Volume Resistivity

Storage & Handling

- Storage Conditions

When stored in a dry place in their original sealed container at a temperature between 2°C and 40°C, Araldite® CY 8763 Resin and Aradur® HY 8763 Hardener have a 12 months shelf life from date of manufacture. These products should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.46 %(W) %(W) Hardener : Resin