Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- EC Number

- 218-645-3

- Function

- Viscosity Modifier,Reactive Diluent

- Single Ingredient

- Yes

- Synonyms

- ((2-methylphenoxy)methyl)oxirane, o-Cresyl glycidyl ether, Ortho-Cresyl Glycidyl Ether

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Advantages

- Reducing viscosity of epoxy systems by addition of reactive diluents will

- Afford the following advantages:

- Easier handling and mixing

- Improved wetting characteristics

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Polymers & Resins

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Formulation Information

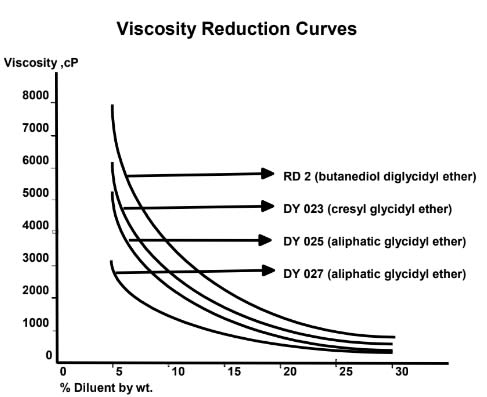

The graph below shows the effect of various Huntsman reactive diluent: Ised with Araldite® GY 6010

Mixing Procedures

- All reactive diluents should be mixed with the resin first. This mixture can be stored for several months. Fillers and hardeners are incorporated just before processing, the latter being stirred in last. Pot life and curing conditions depend on the choice of the epoxy resin and hardener. Since the reactive diluent also has to be cured, it is necessary to adjust the amount of the hardener which is calculated as follows:

- The mixing ratio of Araldite® GY 6010 and ARADUR® 956 is 25 phr, i.e., it takes 25 parts by weight of the ARADUR® 956 to cure 100 parts by weight of Araldite® GY 6010. When added a reactive diluent, e.g., Araldite® DY 023, the hardener ratio should be varied in the same proportion as the epoxy value of the resin / diluent mixture.

Safety & Health

- Handling and Safety Precautions

- Skin and eye irritant. May cause dermatitis and sensitization.

- Avoid contact with eyes, skin and clothing.

- Avoid breathing vapor, mist or spray.

- Promptly remove wet, contaminated, non-impervious clothing; wash before re-use.

- Destroy contaminated leather and absorbent shoes.

- Use with good ventilation.

- Store in cool, ventilated, dry area in closed containers.

- Wash thoroughly after handling.

In case of contact

- Eyes: Immediately flush with water for at least 15 minutes.

- Skin: Promptly wash thoroughly with mild soap and water.

- Inhalation: Remove to fresh air. If breathing is difficult, give oxygen.

- Ingestion: If conscious, give large quantities of water and get medical attention.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

- ARALDITE® DY 023 is supplied in 450 pound steel drums.

Storage & Handling

- Shelf Life Information

- This product has a minimum shelf life of one year when stored in unopened sealed containers in a dry place at room temperature.

Other

- Appearance

- Clear, no contamination

- Color (SDS)

- Colorless

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 175.0-190.0 g/eq g/eq - Physical Properties

Value Units Test Method / Conditions Density 1.08 g/cm³ g/cm³ At 25°C Flash Point 116.0 °C °C Closed Cup Viscosity 5.0-25.0 mPa.s mPa.s At 25°C