Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Diluent,Reactive Diluent

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Labeling Claims

- Properties

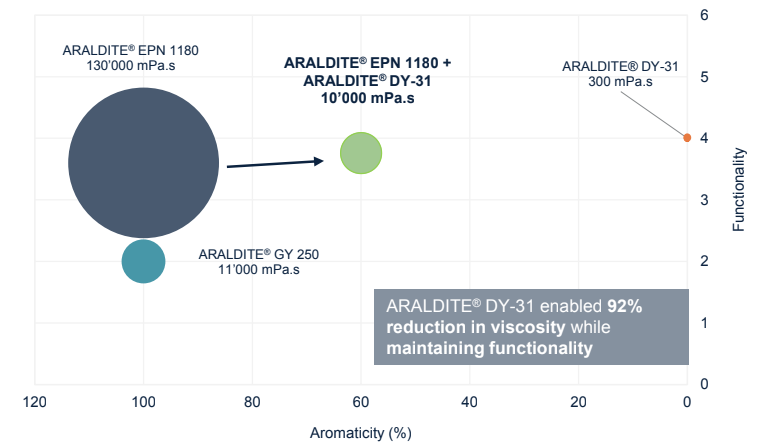

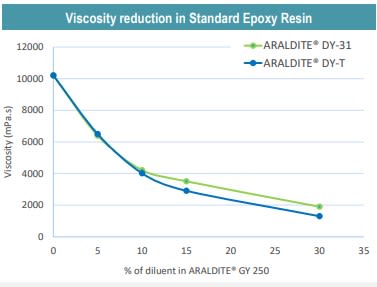

Due to their structure, reactive diluents have low viscosity. ARALDITE® DY 31 is a polymer.

The incorporation of ARALDITE® DY 31 has the following effects:

- A reduction of viscosity when used in a Standard Epoxy resin

- High reactivity is maintained (potentially increased)

- Practically no reduction of hardness

- A slight decrease of warm water resistance

- A slight reduction of acid resistance

- High resistance to solvents and ammonia

- The best diluent for Glass Transition retention

The reactive diluent in the resin component should not exceed 20%.

Applications & Uses

- Adhesive & Sealant End Applications

- Applicable Processes

- Coating End Applications

- Industrial Additives End Use

- Markets

- Applications

- Application Information

Unmodified bisphenol-A and bisphenol-A/F epoxy resins - such as ARALDITE® GY 250, GY260, GY 261, GY 266, PY 302-2 or PY 304 - are mixed with ARALDITE® DY 31 to produce low-viscosity epoxy resins for solvent-free coatings, flooring compounds and Adhesive/mastics.

ARALDITE® DY 31 should preferably be used when reactivity, hardness and resistance to warm water, solvents and ammonia are to be maintained.- 100% Solids chemical resistant coatings

- Concrete crack repair

- Coatings for containment areas

- High-performance adhesives

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Data

ARALDITE® DY-31 high-performance reactive diluent

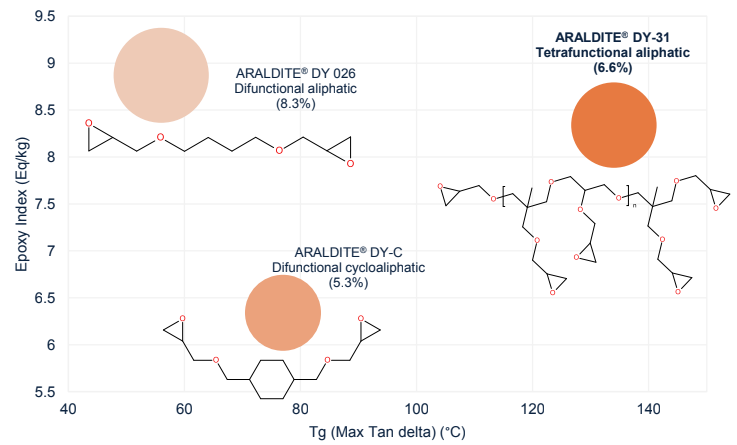

Reduce viscosity of a standard Epoxy resin while maintaining Tg of the formulations, mechanical and chemical resistance properties. CMR-freeDilution without sacrificing functionality nor hydrophobicity

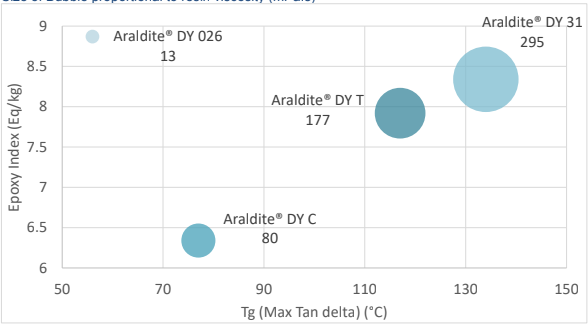

Size of Bubble Viscosity (mPa.s)

Size of Bubble proportional to water absorption after 3 d in boiling water Name (--%)

- Test Data

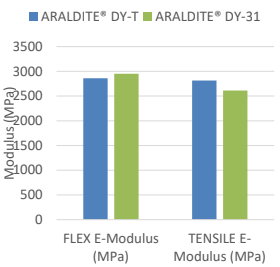

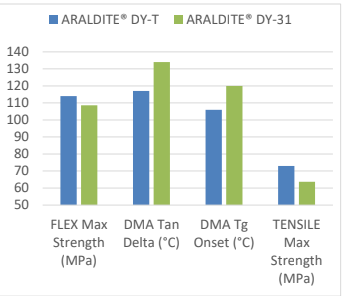

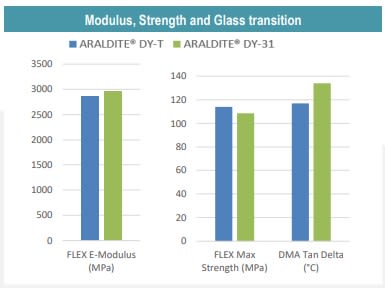

Comparison of ARALDITE® DY 31 with ARALDITE® DY-T: Mechanical properties when fully cured with ARADUR® 20315. Resin + hardener mixed at stoichiometry Cure profile: 1 h at 80°C + 1 h at 120°C + 1 h at 150°C Epoxy content of ARALDITE® DY 31 being higher than ARALDITE® DY-T leads to a different ratio between resin and hardener leading to a Higher Tg and a lower elongation at break. Other parameters are very similar.

Size of Bubble proportional to resin viscosity (mPa.s)

- Technical Graphs

The larger epoxy content of ARALDITE® DY-31 vs. ARALDITE® DY-T leads to a different ratio between resin and hardener resulting in a higher glass transition temperature and a lower elongation at break.

ARALDITE® epoxy resins fully cured with IPDA based hardener ARADUR® 20315 mixed at stoichiometry I Cure profile: 1 h at 80°C + 1 h at 120°C + 1 h at 150°C

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ARALDITE® DY 31 should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40 °C. The product should not be stored exposed to direct sunlight.

- Handling Information

- Mandatory and recommended industrial hygiene procedures should be followed whenever our products are being handled and processed.

Other

- Appearance

- Clear liquid

- Color (SDS)

- Yellow

- Immiscible In (SDS)

- Water

- Odor

- Slight

- Physical Properties

Value Units Test Method / Conditions Glass Transition Temperature (Tg) 134.0 °C °C Viscosity 200.0-400.0 mPa.s mPa.s Falling Ball Viscometer at 25°C Viscosity 200.0-400.0 mPa.s mPa.s ISO 12058 at 25°C