Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Name

- Function

- Reactive Diluent

- Single Ingredient

- Yes

- Synonyms

- 1,4-Bis(2,3-Epoxypropoxy)Butane, B14DODGE

- Technologies

- Product Families

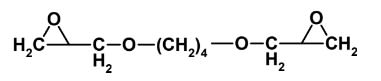

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Properties

Key Properties

Due to their low molecular weight, reactive diluents have low viscosity. On the other hand their vapour pressure is higher and their physiological effectiveness greater than in the case of unmodified epoxy resins. The incorporation of ARALDITE® DY-D has the following effects:

- A fair to good reduction of viscosity

- A slight decrease of reactivity

- An improved processability

- Practically no reduction of hardness

- A poor warm water resistance

- A clearly decreased acid resistance

- High resistance to solvents and ammonia.

Applications & Uses

- Compatible Polymers & Resins

- Markets

- Applications

- Product Applications

- Unmodified bisphenol-A and bisphenol-A/F epoxy resins - such as ARALDITE® GY 250, GY 260, GY 261, GY 266, PY 302-2 or PY 304 - are mixed with ARALDITE® DY-D to produce low viscosity epoxy resins for solvent-free coatings, flooring compounds and mastics. ARALDITE® DY-D is very versatile, as it changes properties of binder systems only slightly. It causes pronounced skin irritation, special attention to precautions as ventilation, gloves and protective cream must be given.

Key Properties

Due to their low molecular weight, reactive diluents have low viscosity. On the other hand their vapour pressure is higher and their physiological effectiveness greater than in the case of unmodified epoxy resins. The incorporation of ARALDITE® DY-D has the following effects:

- A fair to good reduction of viscosity

- A slight decrease of reactivity

- An improved processability

- Practically no reduction of hardness

- A poor warm water resistance

- A clearly decreased acid resistance

- High resistance to solvents and ammonia.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Formulation Information

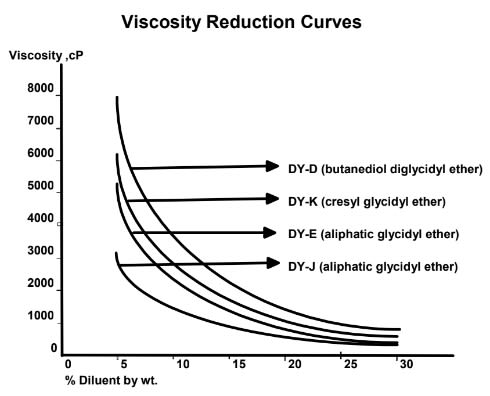

The graph below shows the effect of various Huntsman reactive diluents used with Araldite® GY 6010 epoxy.

Viscosity Reduction at 25°C of Araldite® GY 6005 & Araldite® GY 6020 with Araldite® DY-D

Araldite® DY-D Araldite®GY 6005 (cP) Araldite®GY 6020 (cP)

0 % 9100 16500 15 % 1200 2700 25 % 600 800 35 % 360 800 45 % 230 500

Safety & Health

- Hazardous Decomposition and Handling Precautions

- Hazardous decomposition products (when disposed of in fire) carbon monoxide, carbon dioxide and other toxic gases and vapours.

- Handling Preacutions: Mandatory and recommended industrial hygiene procedures should be followed whenever our products are being handled and processed.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Condition

- ARALDITE® DY-D should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40°C. The product should not be stored exposed to direct sunlight.

Other

- Appearance

- Clear liquid

- Color (SDS)

- Clear Colorless

- Odor

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 118.0-125.0 g/eq g/eq ISO 3001 - Physical Properties

Value Units Test Method / Conditions Density 1.08 g/cm³ g/cm³ ISO 1675 at 20°C Flash Point 138.0 °C °C Closed Cup Viscosity 15.0-25.0 - ISO 3219 at 25°C Viscosity 15.0-25.0 - Rotational Viscometer at 25°C