Enhanced TDS

Identification & Functionality

- Blend

- No

- CAS Number

- 71604-74-5

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Binder & Resin,Resins, Binders & Matrix Materials

- Single Ingredient

- Yes

- Technologies

- Product Families

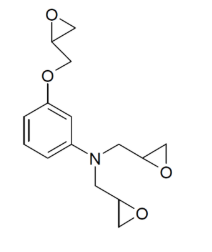

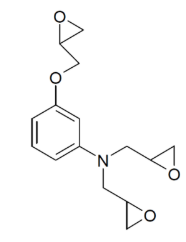

- Chemical Structure

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Materials Features

- Features

- Low viscosity resin for a number applications, such as: Resin Transfer Molding (RTM), Hot melt prepregs, Filament winding, and Pultrusion.

- High stiffness for cured products.

- High hot–wet performance.

- Good toughness behavior.

- Product Features

- Low viscosity resin for a number applications, such as: Resin Transfer Molding (RTM)

- Hot melt prepregs, Filament winding, and Pultrusion

- High stiffness for cured products

- High hot–wet performance

- Good toughness behavior

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Substrates & Surfaces

- Composites End Use

- Composites Processing Methods

- Markets

- Applications

- Application Information

- Facilitate processing, especially of PES toughened compositions

- Higher stability (reactivity) than non distilled version

- Provides higher modulus than p-amino phenol based resins

- Provides higher toughness than p-amino phenol based resins

- Provides similar level of glass transition temperature

Properties

- Physical Form

- Notes

Processing Properties: It's recommended that the components are weighed with an accurate balance to prevent mixing inaccuracies which can affect the properties of the system. The components should be mixed thoroughly to ensure homogeneity.

Typical Physical Properties: Unless otherwise stated, the data were determined with typical production batches using standard test methods. They are typical values only, and do not constitute a product specification. All following properties were determined from samples cured for 2 hours at 120°C + 1 hour at 160°C + 2 hours at 180°C, unless a different cure is specified.

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Test Data

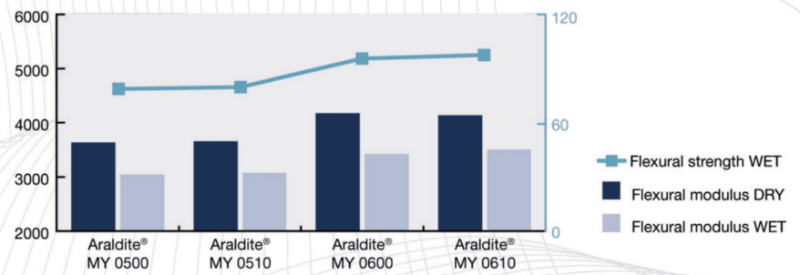

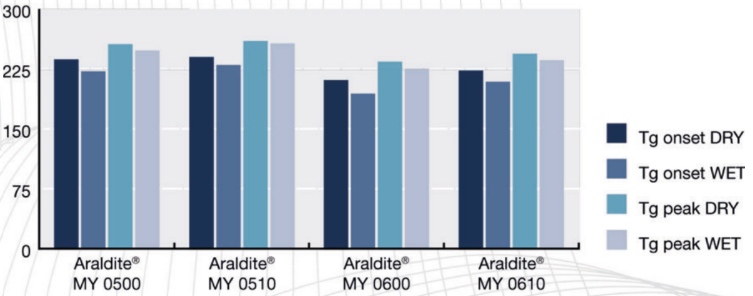

Comparison between TGPAP and TGMAP

Cured with DDS

Flexural modulus and strength (MPa)

Glass transition temperature - Tg DMA (°C)

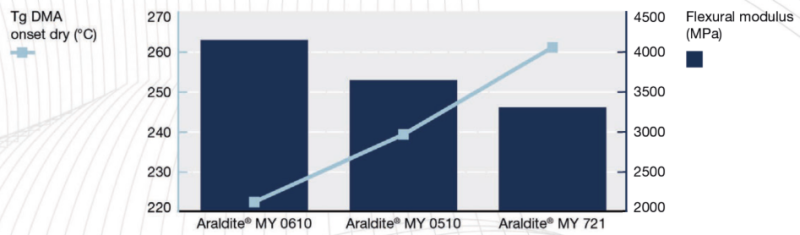

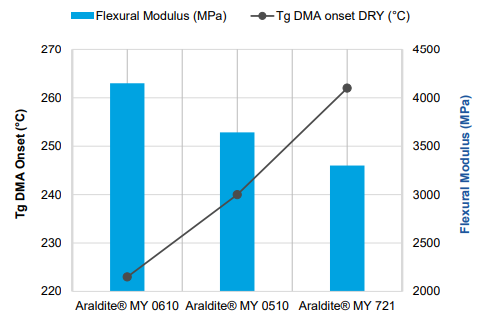

Comparison between TGPAP, TGMAP and TGMDA

Cured with DDS

Glass transition temperature (°C) and modulus (MPa)

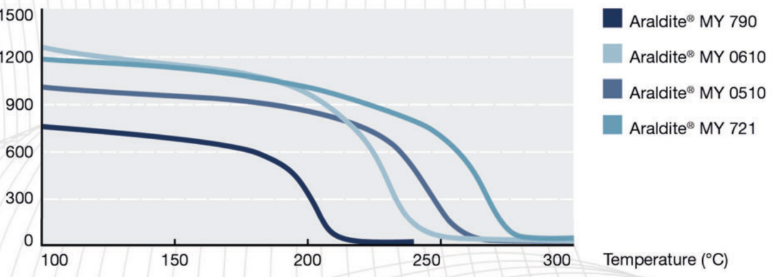

Comparison with DGEBA

Cured with DDS

Glass transition temperature (°C) by DMA

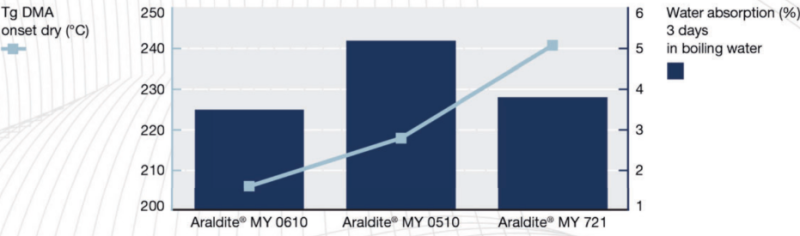

Ultimate Tg and water absorption

Cured with DICY

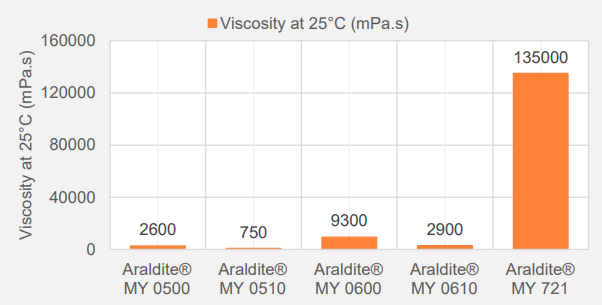

- Viscosity Graph

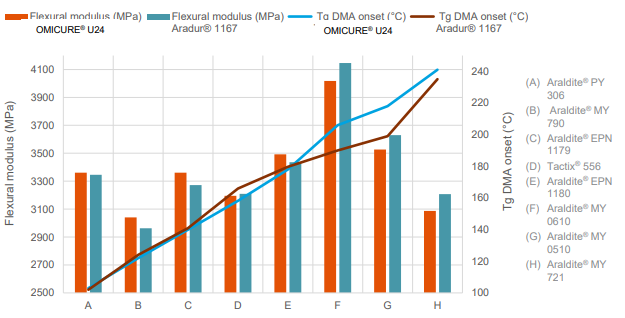

- Thermo-mechanical Properties vs Resin Type

- Graphical Data

Resins + ARADUR® 9664-1 mixed at stoichiometry

Cure profile: 2h at 150°C + 4h at 180°C + 2h at 200°C

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

ARALDITE® MY 0610 Resin should never be stored near warm areas, particularly near heat sources or hot equipment, or even in direct sunlight, because violent exothermic reaction or explosion may result. Store in a sealed container at or below 5°C (40 °F). Maximum temperature this product should be subjected to while thawing for use should not exceed 40°C (100°F). Under these storage conditions the shelf life is 12 months (from date of manufacture). To facilitate handling of ARALDITE® MY 0610 as a workable liquid, warm the container gradually by letting it stand in an area at room temperature (approximately 24°C (75 °F) prior to use. Never accelerate warming by using hot ovens, band heaters, hot plates, open flames, or any means, which could cause a “hot spot”. Such practices may initiate violent exothermic reaction or explosion. Contamination, especially by acidic or basic substances, may also start a violent exothermic reaction and must be avoided.

- Storage Information

ARALDITE® MY 0610 Resin should never be stored near warm areas, particularly near heat sources or hot equipment, or even in direct sunlight, because violent exothermic reaction or explosion may result. Store in a sealed container at or below 5°C (40 °F). Maximum temperature this product should be subjected to while thawing for use should not exceed 40°C (100°F). Under these storage conditions the shelf life is 12 months (from date of manufacture).

To facilitate handling of ARALDITE® MY 0610 as a workable liquid, warm the container gradually by letting it stand in an area at room temperature (approximately 24°C (75 °F) prior to use. Never accelerate warming by using hot ovens, band heaters, hot plates, open flames, or any means, which could cause a “hot spot”. Such practices may initiate violent exothermic reaction or explosion. Contamination, especially by acidic or basic substances, may also start a violent exothermic reaction and must be avoided.

Other

- Appearance

- Clear yellow liquid

- Color (SDS)

- Yellow

- Odor (SDS)

- Slight

- Mechanical Properties

Value Units Test Method / Conditions Flexural Strength 23000.0 psi psi ISO 178 - Physical Properties

Value Units Test Method / Conditions Density 1.21-1.22 g/cm³ g/cm³ ISO 1675 at 25°C Flash Point min. 100.0 °C °C Pensky-Martens Closed Cup (PMCC) Flash Point min. 100.0 °C °C ISO 2719 Glass Transition Temperature (Tg) 225.0-240.0 °C °C Dynamic Mechanical Analysis (DMA) Glass Transition Temperature (Tg) 215.0-220.0 °C °C Thermomechanical Analyzer - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Storage Temperature (SDS) 2.0-8.0 °C °C