Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Low viscosity and good impregnation capability

- Solvent free system

- Long pot-life due to high latency (in absence of tape catalyst)

- Excellent mechanical and electrical end properties.

- Thermal class H according IEC 60216

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Product Applications

Full-bath impregnation of motors and generators with medium and high power ratings and impregnation of single conductors (Roebel bars) in combination with porous mica-tapes

Properties

- Physical Form

Technical Details & Test Data

- Processing Information

Global processing

- Processing details depend very much on the machine type, on customer s defined parameters and type of mica tapes.

- Generally the VPI system is used in impregnation vessels up to 30 tons where the rotor or stator are impregnated at elevated temperatures.

- Machine parts usually are preheated (also under vacuum) in order to remove moisture and to reduce viscosity during impregnation.

- After impregnation the VPI bath is pumped into storage tanks and cooled down to 5 to 10°C and should be stored in dry conditions in order to obtain a long bath life.

- Actual bath life depends on additional parameters, e.g. impregnation temperature and duration of impregnation, impurities in the bath, wash-out of catalyst from mica tapes into the unaccelerated resin system (B), replenishment rate, moisture exposure etc.

- The viscosity of the bath should be checked periodically in order to maintain a suitable viscosity for impregnation. Impregnated, yet uncured machine parts in unconditioned atmosphere may pick up moisture.

- Therefore curing directly after impregnation or storage in a moisture controlled area is recommended. Generally machine parts are rotated when removed from the bath and during the first part of curing in order to avoid drip off.

- Evaporation of hardener during the vacuum cycle leads to a change in the resin/harde-ner ratio in the bath and has to be compensated.

- Therefore replenishment mixing ratios of 100 to 120 pbw. of hardener ARADUR® HY 1102 per 100 pbw ARALDITE® MY 790-1 are generally used.

- Replenishment mixing ratios depend on actual processing parameters and conditions and have to be evaluated at the customer site.

- Due to the excellent latency of the system ARALDITE® MY 790-1 / ARADUR® HY 1102 / ACCELERATOR DY 9577 / ACCELERATOR DY 073-1 the replenishment volume to maintain a constant viscosity is comparatively small, even if impregnation is performed at 40-50°C.

On single coils and Roebel-bars the mica insulation is normally covered with a tight glass tape to prevent drainage of the impregnation resin.

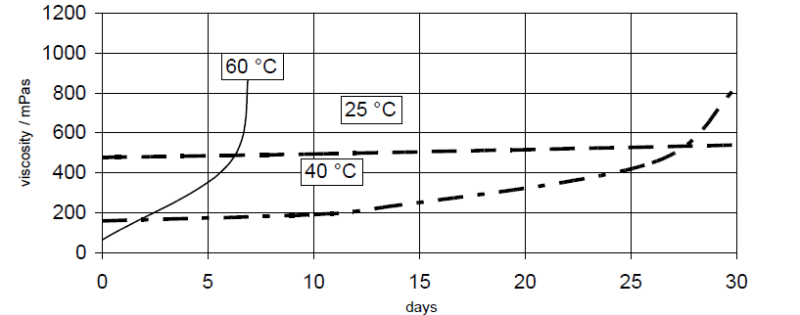

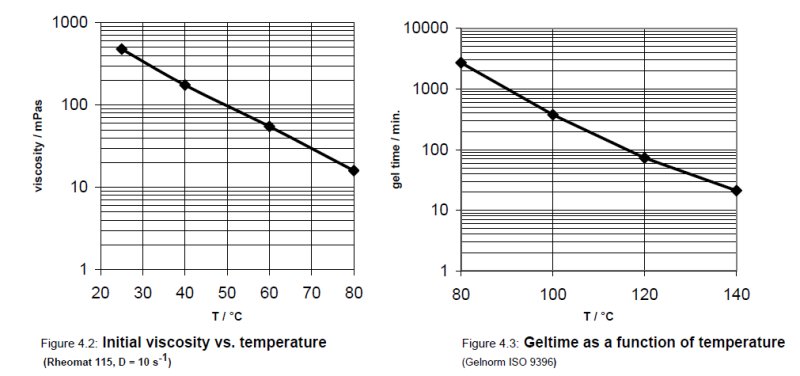

Viscosity increase and gel time at various temperatures, refer to Fig. 4.1 and Fig. 4.3.

Specific instructions

Depending on the insulation materials and the accelerating agent in use, a ramped curing schedule is recommended. In systems with high reactivity, where the accelerator can be included in the mica-tape, a fast gelation can be obtained with a temperature-shock, and draining can so be reduced or avoided.

Standard curing with the standard accelerated mixture (System A) is:

12 h at 90°C plus 18 h at 140°CPrecaution

- To determine whether crosslinking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature.

- Different gelling and cure cycles in the manufacturing process could lead to a different crosslinking and glass transition temperature respectively.

Processing Data

Viscosity

Figure 4.1: Viscosity increase at 25, 40 and 60 °C /with accelerator) (measurements with Rheomat 115, shear rate D = 10 s⁻¹)

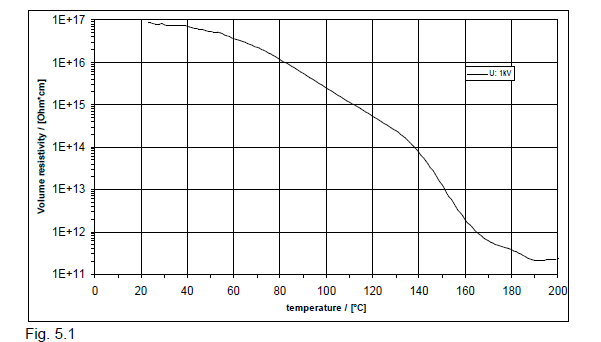

Replenishment to maintain a stable viscosity: (see also Fig.5.1)

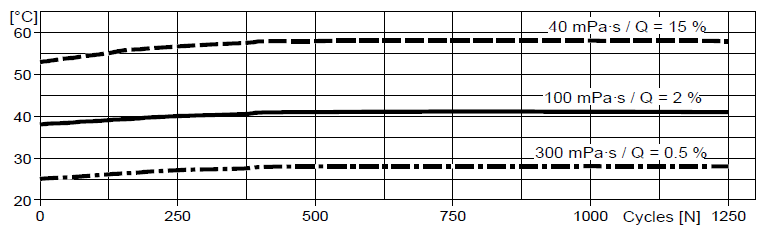

Impregnation viscosity 40 mPa s 100 mPa s 300 mPa s Impregnation temperature 56°C 41°C 28°C Duration of the impregnation 4 h 4 h 9 h Storage temperature 10°C 10°C 10°C Storage time 20 h 20 h 15 h Make-up rate (Q) per cycle (N) 15 % 2 % 0.5 %

Fig.5.1: Bath temperature v number of impregnation cycles (N) and make-up rate (Q) in % 1 cycle = 24h (Impregnation and storage time) (Criteria see page 3)

Theoretical bath stability calculated for System A with the computer program GTRAN

Viscosity increase with 100 pbw ARALDITE® MY 790-1 : 120 pbw ARADUR® HY 1102 (without accelerator)

Viscosity at 70°C mPa s 17 - 19 viscosity after 10 d / 70°C at 70°C mPa s < 21 viscosity difference after 10d / 70°C mPa s < 1.4 viscosity difference after 20 h / 100°C mPa s < 1.4 Mechanical and Physical Properties

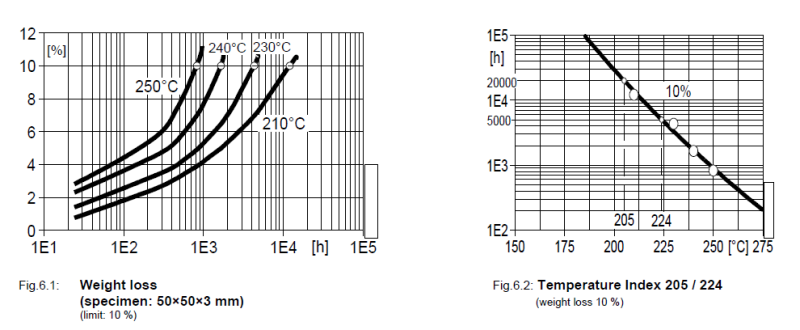

Tensile strength ISO 527 MPa 35 - 45 Elongation at break ISO 527 % 1.2 - 1.5 E modulus from tensile test ISO 527 MPa 3'000 - 4'000 Flexural strength at 23°C ISO 178 MPa 130 - 140 Surface strain at 23°C ISO 178 % 4.5 - 5.5 E modulus from tensile test ISO 178 MPa 3'000 - 4'000 Glass transition temperature (DSC) ISO 11357-2 °C 135 - 145 Coefficient of linear thermal expansion Mean value for temperature range: 20-80°C ISO 11359-2 ppm / K 61 - 63 Thermal conductivity similar to ISO 8894-1 W/mK 0.15 - 0.20 Thermal endurance profile (TEP) IEC 60216 Fig. 6.1/6.2 Temperature index (TI): weight loss 20'000 / 5'000 h °C 205 / 224 Thermal ageing class (20'000 h) IEC 60085 H Water absorption (specimen: 50x50x4 mm) ISO 62 10 days at 23°C % by wt 0.35 - 0.45 60 min at 100°C % by wt 0.15 - 0.20 Decomposition temperature

(heating rate: 10K/min)DTA °C ≥ 350 Note: Determined on unreinforced, cast standard test specimen at 23°C Cured for 24h at 80°C + 10h 140°C

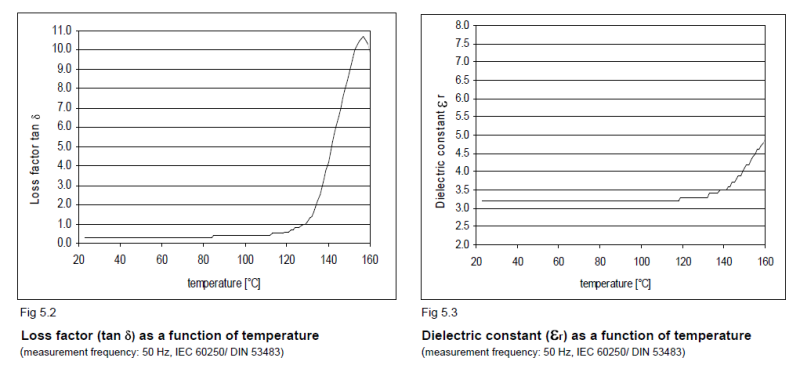

Electrical Properties

Breakdown strength 3 mm plates IEC 60243-1 kV/mm 23 - 28 HV arc resistance IEC 61621 s 80 - 100 Tracking resistance with solution A IEC 60112 CTI > 600 - <1 Tracking resistance with solution B IEC 60112 CTI > 600 M - <1 Electrolytic corrosion IEC 60426 grade A1

Note: Determined on unreinforced, cast standard test specimen at 23°C Cured for 24h at 80°C + 10h 140°C

Volume resistivity ( ) as a function of temperature (measurement voltage: 1000 V, IEC 60093/ DIN 53482)

Safety & Health

- Safety Information

First Aid

- Contamination of the eyesby resin, hardener or casting mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes.

- A doctor should then be consulted.

- Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above).

- A doctor should be consulted in the event of severe irritation or burns.

- Contaminated clothing should be changed immediately.

- Anyone taken ill after inhaling vapours should be moved out of doors immediately.

- In all cases of doubt call for medical assistance.

Storage & Handling

- Handling Information

Safety Precautions Protective clothing Yes Gloves Essential Arm protectors Recommended when skin contact likely

Goggles/safety glasses Yes Respirator/dust mask Recommended Skin Protection Skin protection before starting Apply barrier cream to exposed skin

Skin protection after washing Apply barrier or nourishing cream

Cleansing of contaminated skin Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Clean shop requirements Cover workbenches, etc. with light coloured paper. Use disposable breakers, etc.

Disposal of spillage Soak up with sawdust or cotton waste and deposit in plastic-lined bin

Ventilation Ventilation of workshop Renew air 3 to 5 times an hour

Ventilation of workplace Exhaust fans. Operatives should avoid inhaling vapours.

- Storage Conditions

- Store the components at 18-25°C, in tightly sealed and dry original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- Product specific advise regarding storage can be found on product label.

- After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.0004-0.0016 %(W) %(W) Accelerator : Resin Mix Ratio 0.9 %(W) %(W) Hardener : Resin