Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Casting Resin,2K (2 Component) Potting Compound

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Excellent hydrolytic stability giving improved reliability

- 100% solids for improved ease of use and handling

- Low outgassing, meeting NASA requirements

- High thermal shock resistance offering greater component protection and reliability.

- Product Benefits

- Excellent hydrolytic stability giving improved reliability

- 100% solids for improved ease of use and handling

- Low outgassing, meeting NASA requirements

- High thermal shock resistance offering greater component protection and reliability.

Applications & Uses

- Application Area

- Application Information

- Stress sensitive components

- Non-terrestrial encapsulating applications

- System Preparation

Exposure of part A to low temperatures for prolonged periods may cause crystallization. Part A must be re-liquified by heating to 158°F (70°C). Heat part A until clear amber solution is achieved. Remove container from oven. Do not disturb contents. Allow material to cool to 77ºF to 104ºF (25°C - 40°C) in a controlled environment, do not force cool.

Measure height of the precipitate from outside of bottle. Do not use if level of precipitate is above 3/8 inches (0.6cm) or if liquid remains cloudy or contains gelled particles. Contact our Customer Service Department with lot number, date received and condition of bottle.

Material is ready for use if level of precipitate is below 3/8 inches. Do not agitate. Slowly decant clear resin out of the bottle without disturbing the precipitate. Enough material has been packaged to allow for any precipitate and to assure sufficient Part A. For best result, filter Part A through a nylon sieve, 10 - 25 micron size.

Use entire bottle so remaining material will not be contaminated with moisture. If this is not possible, any remaining material must be blanketed with dry nitrogen or argon and the cap securely tightened. Store at 77ºF to 104ºF (25° - 40°C) for best long-term stability.

MIXING:

Container should be plastic, glass, or metal. Paper and wooden containers or utensils should be avoided because of their high moisture content. Weigh Part B into container first. Add Part A to container. (Do not use Part A if precipitate level is greater than 3/8 inches).

Slow machine mixing or hand stirring will minimize air entrapment. Complete and thorough mixing of Part A and B is essential for optimum end properties. Mixture may be vacuumed by drawing 29 - 29.5 inches of Hg for 2 - 3 minutes. Enough room should be allowed for expansion inside the container as the material will tend to rise and “break”.

- Applications

- Stress sensitive components

- Non-terrestrial encapsulating applications

Properties

- Mixing

- Container should be plastic, glass, or metal. Paper and wooden containers or utensils should be avoided because of their high moisture content. Weigh Part B into container first. Add Part A to container. (Do not use Part A if precipitate level is greater than 3/8 inches).

- Slow machine mixing or hand stirring will minimize air entrapment. Complete and thorough mixing of Part A and B is essential for optimum end properties.

- Mixture may be vacuumed by drawing 29 - 29.5 inches of Hg for 2 - 3 minutes. Enough room should be allowed for expansion inside the container as the material will tend to rise and “break”.

- System Preparation

Exposure of part A to low temperatures for prolonged periods may cause crystallization. Part A must be re-liquified by heating to 158°F (70°C). Heat part A until clear amber solution is achieved. Remove container from oven. Do not disturb contents. Allow material to cool to 77oF to 104oF (25°C - 40°C) in a controlled environment, do not force cool.

Measure height of the precipitate from outside of bottle. Do not use if level of precipitate is above 3/8 inches (0.6cm) or if liquid remains cloudy or contains gelled particles. Contact our Customer Service Department with lot number, date received and condition of bottle.

Material is ready for use if level of precipitate is below 3/8 inches. Do not agitate. Slowly decant clear resin out of the bottle without disturbing the precipitate. Enough material has been packaged to allow for any precipitate and to assure sufficient Part A. For best result, filter Part A through a nylon sieve, 10 - 25 micron size.

Use entire bottle so remaining material will not be contaminated with moisture. If this is not possible, any remaining material must be blanketed with dry nitrogen or argon and the cap securely tightened. Store at 77°F to 104°F (25° - 40°C) for best long-term stability.

- Typical Cure Characteristics

Unless otherwise stated, the results in the following figures are based on the bonding of standard specimens of 114 x 25 x 1.6 mm aluminum alloy strips.The bonding surface in each case was 12.5 x 25 mm.These data graphs are the result of testing typical production batches using standard test methods. They are for technical information only and are not intended toConstitute product specifications.

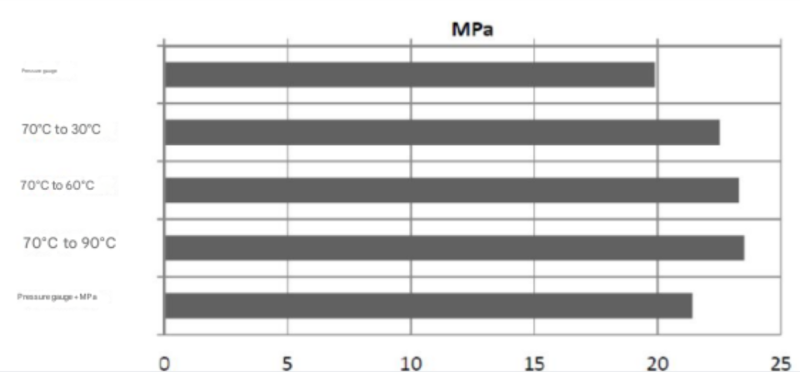

Typical average lap shear strength of metal-to-metal bonds (ISO 4587) (Typical average)

Curing: 16 hours at 40°C, test temperature 23°C, pre-treatment - sandblasting

Glass transition temperature (typical average)

Curing: 1 hour at 80°C (DMA)

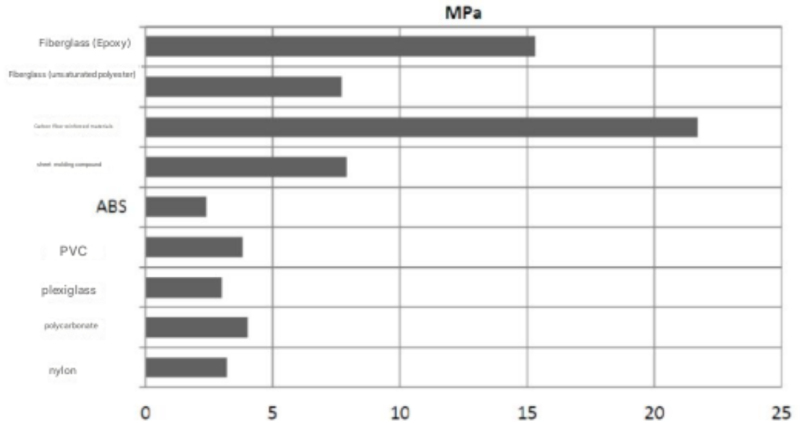

Average lap shear strength of typical plastic-to-plastic bonds (ISO 4587) (typical average values)

Curing: 16 hours at 40°C, test temperature 23°C. Pretreatment - Mild abrasion and alcohol degreasing.

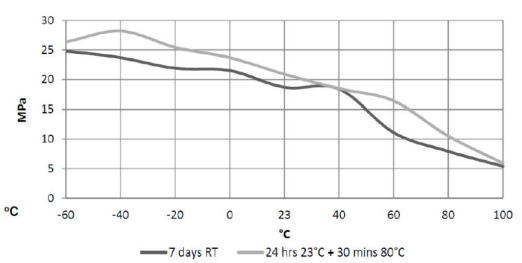

Lap shear strength vs. temperature (ISO 4587) (typical average values)

Aluminium sheet, pre-treatment - sandblasting. Curing: 7 days at room temperature or 24 hours at 23°C + 30 minutes at 80°C

DMA (ISO 6721) (typical average)

Temperature G’ -50°C 1.8 GPa 0°C 1 GPa 20°C 900 GPa 50°C 540 GPa 75°C 61 MPa 100°C 12 Mpa Flexural properties (ISO 178) (typical average) Curing: 16 hours at 40°C. Test temperature is 23°C

Flexural strength : 40-50 MPa

Flexural modulus : 1600-2000 MPa

Tensile properties (ISO 178) (typical average values) Curing: 16 hours at 40°C. Test temperature is 23°C

Tensile Strength : 30-40 Mpa

Tensile modulus : 1500-1800 Mpa

Elongation at break : 3-5%

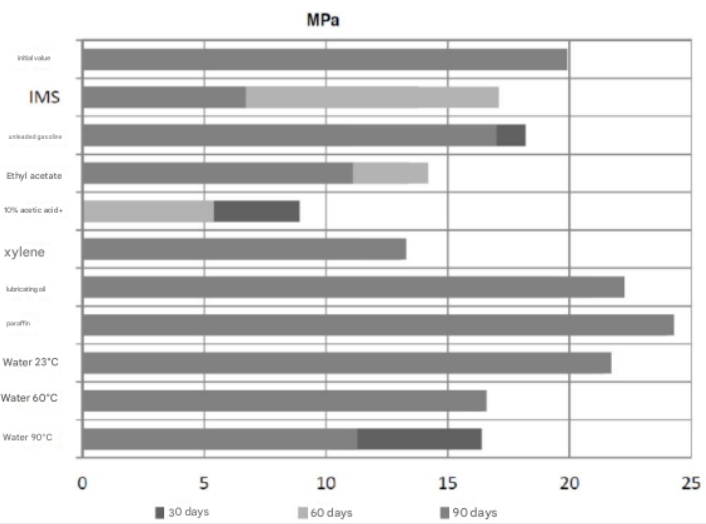

Lap shear strength of various media immersion tests (typical average values)

Aluminium sheet, pre-treatment - sandblasting. Curing: 16 hours at 40°C, test temperature 23°C

Unless otherwise stated, lap shear strength values are given after immersion at 23°C for 30, 60, and 90 days.

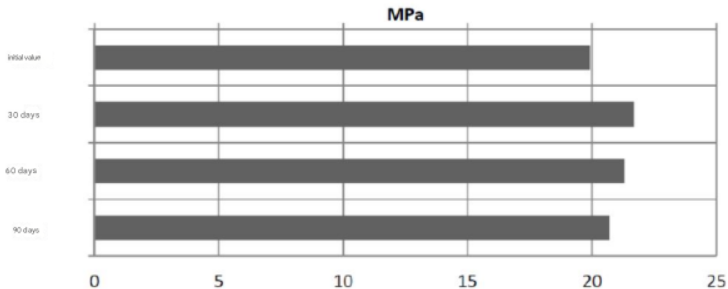

Lap shear strength for tropical climates (typical averages)

(40°C/92% RH) Aluminum, pre-treated - sandblasted. Cured at 40°C for 16 hours, tested at 23°C

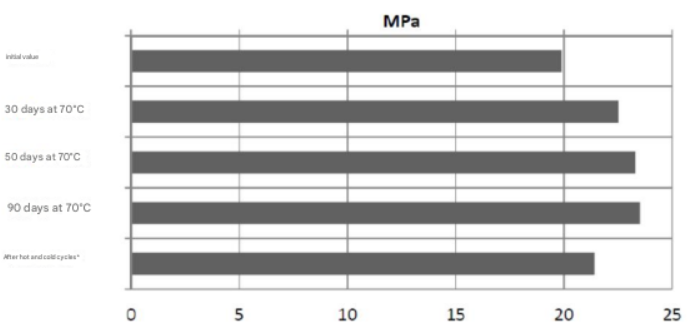

Heat aged lap shear strength (typical average)

Aluminum sheet, pre-treatment - sandblasting. Curing at 40°C for 16 hours, testing at 23°C

Hot and cold cycle: 25 times, 6 hours each time, from -30°C to 70°C.

Technical Details & Test Data

- Recommended Cure Time

Recommended cure times* : 24 hours at 77ºF (25°C) or 8 hours at 203ºF (95°C)

* Cure schedule results in approximately 90% of final properties. Additional room temperature or elevated temperature curing is required for 100% properties.

Storage & Handling

- Storage Information

When stored in a dry place in its original sealed original container at a temperature between 64°F and 104°F (18°C and 40°C) the components of Arathane® 5753-A/B (LV) have a six months shelf-life. The components should not be exposed to direct sunlight. Arathane® 5753-A/B (LV) is moisture sensitive. Partial containers should be blanketed with dry nitrogen or argon prior to being tightly resealed after each use.

Work in a well-ventilated area and use clean, dry tools for mixing and applying. For two component systems, combine the resin and hardener according to mix ratio. Mix together thoroughly and use immediately. Material temperature should not be below 64°F (18°C) when mixing.

Other

- Physical Properties

Value Units Test Method / Conditions Viscosity 70000.0 cPs cPs Brookfield Viscometer at 25°C, spindle #6, 10 rpm - Application Information

Value Units Test Method / Conditions Mix Ratio 0.2 %(W) %(W) Hardener : Resin