Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Function

- Etchant, Cleaner

- Industrial Additives Functions

- Technologies

- Product Families

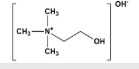

- Chemical Structure

Features & Benefits

- Industrial Additives Features

- Product Features

- Organic base

- High purity, low trace metal

- Available at 45 wt%

- Water or solvent based

- TMAH replacement

- Developer, stripper, and PERR

- Etching agent

- CMP slurries and pCMP Cleans

Applications & Uses

- Applicable Processes

- Industrial Additives End Use

- Markets

- Applications

Properties

- Physical Form

- Notes

* Thickness measured with Napson Cresbox 4 point-probe tester and Filmetrics.

Regulatory & Compliance

Technical Details & Test Data

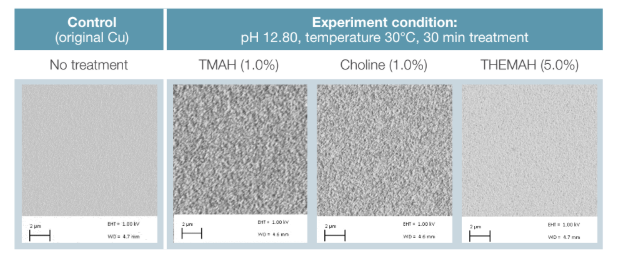

- Treatment of Copper Wafer

- Cu wafer treated with E-GRADE® THEMAH and E-GRADE® CHOLINE HYDROXIDE demonstrated smoother surfaces comparing to Cu treated with TMAH.

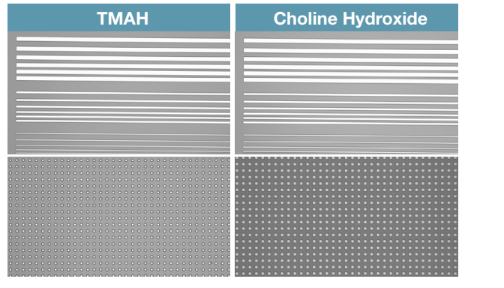

- TMAH diagram

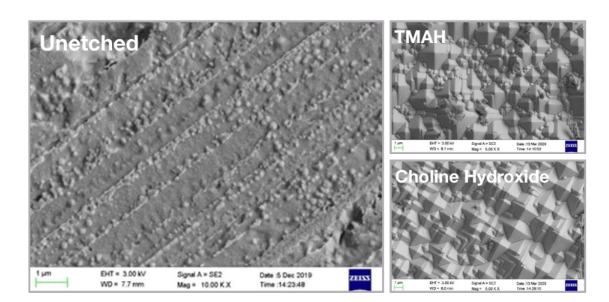

- Silicon wafers, etched with E-GRADE® Choline Hydroxide, demonstrate significant reductions in reflectivity and improvement in uniformity when compared to wafers treated with TMAH. This texturization reduces light reflection and improves absorption for photovoltaic devices.

- Positive tone Novolak photoresist is well developed at room temperature with E-GRADE® Choline Hydroxide.

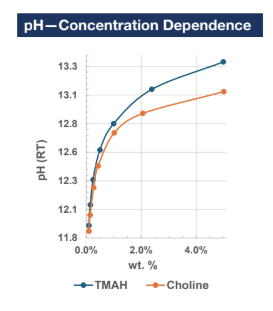

- pH Dependance

- Concentration dependence of pH values for TMAH and Choline in water.

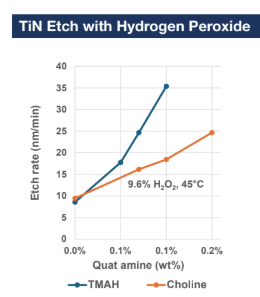

- TiN Etch with Hydrogen Peroxide

- At proper pH and concentration, E-GRADE® Choline Hydroxide with H₂O₂ can be used for TiN etch (etch rate > 20 nm/min). The degradation rate of H₂O₂ with Choline Hydroxide was observed to be much slower than with TMAH. Degradation rate is based on 24 hr average at 45°C.

H₂O₂ (wt %) Quat pH at 45℃ TiN (nm/min) Cu (nm/min) H₂O₂ degradation (%/hr)

8.0% TMAH 7.96 18.67 -0.31 0.071 COH 8.05 19.02 0.39 0.058 9.6% TMAH 8.07 33.3 0.66 0.148 COH 8.03 24.66 0.47 0.098 - Photoresist Development - Concentration Dependence

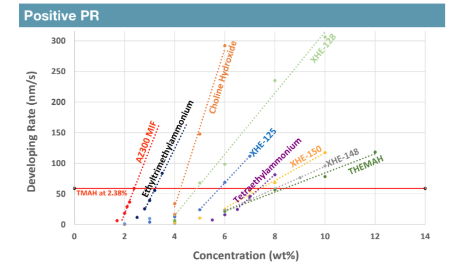

- Choline Hydroxide, XHE-125, and XHE-128 have comparable developing rates relative to 2.38 wt% TMAH for positive PR

- Developing rates can be optimized across a broad working window

- Developing rates are linear with concentration, above a minimum concentration

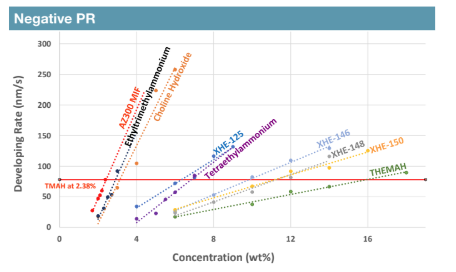

- Choline Hydroxide demonstrated good performance for negative PR

- XHE-125 has similar performance, increasing the concentration to 5 wt% to match 2.38 wt% TMAH

- Developing rates have a linear relationship with concentration, even at low concentrations

Packaging & Availability

- Regional Availability

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear

- Odor (SDS)

- Mild amine-like

- Chemical Properties

Value Units Test Method / Conditions pH 2.58 - - Physical Properties

Value Units Test Method / Conditions Molecular Weight 121.0 g/mol g/mol