Enhanced TDS

Identification & Functionality

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Multi-purpose

- Long working life

- Low shrinkage

- Good resistance to dynamic loading

- Bonds a wide variety of materials in common use

- Product Features

- Multi-purpose

- Long working life

- Low shrinkage

- Good resistance to dynamic loading

- Bonds a wide variety of materials in common use

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Product Applications

Application of adhesive

- The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces.

- Huntsman's technical support group can assist the user in the selection of a suitable application method as well as suggest a variety of reputable companies that manufacture and service adhesive dispensing equipment.

- A layer of adhesive 0.002 to 0.004 in (0.05 to 0.10 mm) thick will normally impart the greatest lap shear strength to the joint.

- Huntsman stresses that proper adhesive joint design is also critical for a durable bond.

- The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

- Processing Information

Pretreatment

- The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded.

- At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics) or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low-grade alcohol, gasoline, or paint thinners should never be used.

- The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces.

- Abrading should be followed by a second degreasing treatment.

Regulatory & Compliance

- OEM Specifications

Technical Details & Test Data

- Cure Times to Reach Minimum Shear Strength

Temperature 50°F 59°F 73°F 104°F 140°F 212°F Cure time to reach Lap shear strength > 145 psi 24 hours 12 hours 7 hours 2 hours 30 minutes 6 minutes Cure time to reach Lap shear strength > 1450 psi 36 hours 18 hours 10 hours 3 hours 45 minutes 7 minutes - Typical Physical Properties

- Unless otherwise stated, the data were determined with typical production batches using standard test methods.

- They are typical values only, and do not constitute a product specification.

- Unless a different specification is given, the figures below were all determined by testing standard specimens made by lap-jointing 4.5 x 1 x 0.063 in (114 x 25 x 1.6 mm) strips of aluminum alloy. The joint area was 0.5 x 1 in (12.5 x 25 mm) in each case.

- Samples were cured at 104°F (40°C) for 16 hours and tested at 23°C, unless otherwise noted.

Property Value Test Method Average lap shear strength, metal-metal joints, sand blasting pre-treatment Aluminum 3,771 psi ISO 4587 Steel 37/11 3,626 psi Stainless steel V4A 3,191 psi Galvanized steel 2,611 psi Copper 3,481 psi Brass 3,481 psi Average lap shear strength, plastic-plastic joints, lightly abrade and alcohol degrease pre-treatment GRP 1,639 psi ISO 4587 CFRP 2,770 psi SMC 1,015 psi ABS 798 psi PVC 290 psi PMMA 406 psi Polycarbonate 653 psi Polyamides 580 psi Lap shear strength after immersion in 23°C media (30 days) IMS: 2,756 psi

Gasoline: 0 psi

Ethyl acetate: 2,321 psi

Xylene: 2,901 psi

Lubricating oil: 2,176 psi

Paraffin: 2,321 psi

Water at 73°F: 3,118 psi

Water at 140°F: 1,978 psi

Water at 194°F: 1,595 psiISO 4587 Lap shear strength after immersion in 23°C media (60 days) IMS: 2,611 psi

Gasoline: 2,827 psi

Ethyl acetate: 2,611 psi

Xylene: 2,901 psi

Lubricating oil: 2,611 psi

Paraffin: 2,466 psi

Water at 73°F: 2,756 psi

Water at 140°F: 1,885 psi

Water at 194°F: 1,160 psiISO 4587 Lap shear strength after immersion in 23°C media (90 days) As-made value: 3,735 psi

IMS: 2,756 psi

Gasoline: 3,118 psi

Ethyl acetate: 3,118 psi

Xylene: 3,191 psi

Lubricating oil: 3,191 psi

Paraffin: 3,771 psi

Water at 73°F: 3,597 psi

Water at 140°F: 1,305 psi

Water at 194°F: 290 psiISO 4587 Lap shear strength, exposure to tropical weather* Standard - As Prepared: 3,626 psi

30 days: 1,999 psi

60 days: 1,768 psi

90 days: 1,768 psiISO 4587 / DIN 50015 Lap shear strength, heat aging As-made: 2,901 psi

68°F / 5 years: 2,277 psi

176°F / 60 days: 2,451 psi

176°F / 5 years: 566 psi

248°F / 60 days: 2,176 psi-- Roller peel test 29 pli (5.0 N/mm) ISO 4578 Glass transition temperature, DSC, Tg ~113°F (45°C) Huntsman Electrolytic corrosion, A–A/B 1,2 DIN 53489 Dielectric strength (50 Hz, 75°F)† 25–27 kV/mm (instantaneous), 22–24 kV/mm (1 min) VSM 77170 Water vapor permeability (100°F, 90% RH) 16 g/m² NF 41001 Water absorption 0.8% (24 h at 73°F), 1.3% (30 min at 212°F) ISO 62-80 Thermal conductivity 0.22 W/m·K ISO 8894/90 Shear modulus -58°F (-50°C): 217,557 psi (1.5 GPa)

32°F (0°C): 174,045 psi (1.2 GPa)

122°F (50°C): 29,008 psi (0.2 GPa)

212°F (100°C): 1,015 psi (0.007 GPa)DIN 53445 Flexural strength 8,760 psi (60.4 MPa) ISO 178 Flexural modulus 276,166 psi (1904.1 MPa) ISO 178 Fatigue test on lap joints (load % of static shear strength)‡ 30%: 10⁵–10⁶ cycles

20%: 10⁶–10⁷ cycles

15%: >10⁷ cyclesDIN 53285 - *40/92, DIN 50015; typical average values; test at 23°C.

- †Cure 16 h at 104°F (40°C) or 20 min at 212°F (100°C); Test: 4 days in a conditioning chamber in 40/92 climate as specified by DIN 50015; Rating according to specified standard

- ‡Cure 20 min / 212°F (100°C); Mean static lap shear strength: 2364 psi (16.3 MPa); Test carried out using a load cycle frequency of 90 Hz.

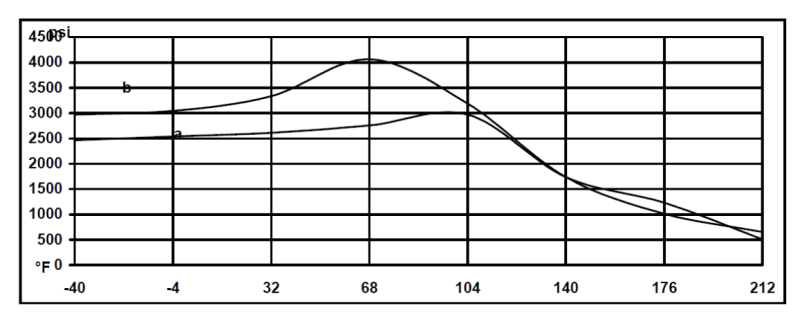

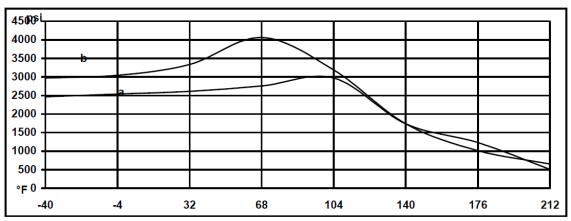

Figure 1. Lap shear strength versus temperature (ISO 4587) (typical average values) Cure: (a) = 7 days at 73°F (23°C); (b) = 24 hours at 73°F (23°C) + 30 min / 176°F (80°C)

- Equipment Maintenance

- All tools should be cleaned with hot water and soap before adhesives residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

- If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

- Processing Information

The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics) or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low-grade alcohol, gasoline, or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

Araldite® 2011 structural adhesive is available in cartridges incorporating mixers and can be applied as ready to use adhesive with the aid of the tool recommended by Huntsman Advanced Materials.

Application of adhesive

The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces. Huntsman's technical support group can assist the user in the selection of a suitable application method as well as suggest a variety of reputable companies that manufacture and service adhesive dispensing equipment. A layer of adhesive 0.002 to 0.004 in (0.05 to 0.10 mm) thick will normally impart the greatest lap shear strength to the joint. Huntsman stresses that proper adhesive joint design is also critical for a durable bond. The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

Equipment Maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Property Key Value Unit Condition Cure Time 24 hours at 50°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time 12 hours at 59°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time 7 hours at 73°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time 2 hours at 104°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time 30 mins at 140°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time 6 mins at 212°F, to reach lap shear strength min. 145 psi (1 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 36 hours at 50°F , to reach lap shear strength min. 1450 psi (10 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 18 hours at 59°F , to reach lap shear strength min. 1450 psi (10 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 10 hours at 73°F , to reach lap shear strength min. 1450 psi (10 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 3 hours at 104°F , to reach lap shear strength min. 1450 psi (10 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 45 mins at 140°F , to reach lap shear strength min. 1450 psi (10 MPa)

Cure Time to Reach LSS > 1450 psi (10 MPa) 7 mins at 212°F , to reach lap shear strength min. 1450 psi (10 MPa)

Typical Physical Properties

Unless otherwise stated, the data were determined with typical production batches using standard test methods. They are typical values only, and do not constitute a product specification.

Unless a different specification is given, the figures below were all determined by testing standard specimens made by lap-jointing 4.5 x 1 x 0.063 in (114 x 25 x 1.6 mm) strips of aluminum alloy. The joint area was 0.5 x 1 in (12.5 x 25 mm) in each case. Samples were cured at 104°F (40°C) for 16 hours and tested at 23°C, unless otherwise noted.

Property Key Value Unit Test Method Condition Average Lap Shear Strength (Aluminum) 3,771 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (Steel) 3,626 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (Stainless steel V4A) 3,191 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (Galvanized steel) 2,611 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (Copper) 3,481 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (Brass) 3,481 psi ISO 4587 Sand blasting pre-treatment

Average Lap Shear Strength (GRP) 1,639 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (CFRP) 2,770 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (SMC) 1,015 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (ABS) 798 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (PVC) 290 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (PMMA) 406 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (Polycarbonate) 653 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Average Lap Shear Strength (Polyamides) 580 psi ISO 4587 Lightly abrade and alcohol degrease pretreatment

Lap Shear Strength 2,756 psi ISO 4587 at 23°C, after immersion media (30 days), IMS

Lap Shear Strength 0 psi ISO 4587 at 23°C, after immersion media (30 days), Gasoline

Lap Shear Strength 2,321 psi ISO 4587 at 23°C, after immersion media (30 days),Ethyl acetate

Lap Shear Strength 2,901 psi ISO 4587 at 23°C, after immersion media (30 days),Xylene

Lap Shear Strength 2,176 psi ISO 4587 at 23°C, after immersion media (30 days),Lubricating oil

Lap Shear Strength 2,321 psi ISO 4587 at 23°C, after immersion media (30 days), Paraffin

Lap Shear Strength 3,118 psi ISO 4587 at 23°C, after immersion media (30 days), Water at 73°F

Lap Shear Strength 1,978 psi ISO 4587 at 23°C, after immersion media (30 days), Water at 140°F

Lap Shear Strength 1,595 psi ISO 4587 at 23°C, after immersion media (30 days), Water at 194°F

Lap Shear Strength 2,611 psi ISO 4587 at 23°C, after immersion media (60 days), IMS

Lap Shear Strength 2,827 psi ISO 4587 at 23°C, after immersion media (60 days), Gasoline

Lap Shear Strength 2,611 psi ISO 4587 at 23°C, after immersion media (60 days), Ethyl acetate

Lap Shear Strength 2,901 psi ISO 4587 at 23°C, after immersion media (60 days), Xylene

Lap Shear Strength 2,611 psi ISO 4587 at 23°C, after immersion media (60 days), Lubricating oil

Lap Shear Strength 2,466 psi ISO 4587 at 23°C, after immersion media (60 days), Paraffin

Lap Shear Strength 2,756 psi ISO 4587 at 23°C, after immersion media (60 days), Water at 73°F

Lap Shear Strength 1,885 psi ISO 4587 at 23°C, after immersion media (60 days), Water at 140°F

Lap Shear Strength 1,160 psi ISO 4587 at 23°C, after immersion media (60 days), Water at 194°F

Lap Shear Strength 3,735 psi ISO 4587 at 23°C, after immersion media (90 days), As-made Value

Lap Shear Strength 2,756 psi ISO 4587 at 23°C, after immersion media (90 days), IMS

Lap Shear Strength 3,118 psi ISO 4587 at 23°C, after immersion media (90 days), Gasoline

Lap Shear Strength 3,118 psi ISO 4587 at 23°C, after immersion media (90 days), Ethyl acetate

Lap Shear Strength 3,191 psi ISO 4587 at 23°C, after immersion media (90 days), Xylene

Lap Shear Strength 3,191 psi ISO 4587 at 23°C, after immersion media (90 days), Lubricating oil

Lap Shear Strength 3,771 psi ISO 4587 at 23°C, after immersion media (90 days), Paraffin

Lap Shear Strength 3,597 psi ISO 4587 at 23°C, after immersion media (90 days), Water at 73°F

Lap Shear Strength 1,305 psi ISO 4587 at 23°C, after immersion media (90 days), Water at 140°F

Lap Shear Strength 290 psi ISO 4587 at 23°C, after immersion media (90 days), Water at 194°F

Lap Shear Strength (Standard - As Prepared) 3,626 psi ISO 4587 / DIN 50015 Exposure to tropical weather (As Prepared)

Lap Shear Strength (After 30 days) 1,999 psi ISO 4587 / DIN 50015 Exposure to tropical weather (30 days)

Lap Shear Strength (After 60 days) 1,768 psi ISO 4587 / DIN 50015 Exposure to tropical weather (60 days)

Lap Shear Strength (After 90 days) 1,768 psi ISO 4587 / DIN 50015 Exposure to tropical weather (90 days)

Lap Shear Strength (As-made value)* 2,901 psi ISO 4587 As-made value Lap Shear Strength (68°F / 5 years)* 2,277 psi ISO 4587 After 68°F exposure for 5 years

Lap Shear Strength (176°F / 60 days)* 2,451 psi ISO 4587 After 176°F exposure for 60 days

Lap Shear Strength (176°F / 5 years)* 566 psi ISO 4587 After 176°F exposure for 5 years

Lap Shear Strength (248°F / 60 days)* 2,176 psi ISO 4587 After 248°F exposure for 60 days

Roller Peel Test 29 pli ISO 4578 Glass Transition Temperature (DSC) 45 °C Huntsman Electrolytic Corrosion** 1,2 DIN 53489 Dielectric Strength 25 - 27 kV/mm VSM 77170 at 24°C, Instantaneous

Dielectric Strength 22 - 24 kV/mm VSM 77170 at 24°C, 1-minute

Water Vapor Permeability 16 g/m² NF 41001 100°F, 90% RH, cure for 5 days at 73°F (23°C)

Water Absorption 0.8 % wt. ISO 62-80 24 hours at 73°F (23°C)

Thermal Conductivity 0.22 W/m·K ISO 8894/90 Cure for 20 min at 100°C, test at 73°F (23°C)

Flexural Strength 60.4 MPa ISO 178 Flexural Modulus 1904.1 MPa ISO 178 Fatigue Test on Simple Lap Joints*** 10⁵ - 10⁶ DIN 53285 Fluctuating load as % of static shear strength

Fatigue Test on Simple Lap Joints*** 10⁶ - 10⁷ DIN 53285 Fluctuating load as % of static shear strength

Fatigue Test on Simple Lap Joints*** 10⁷ DIN 53285 Fluctuating load as % of static shear strength

* - 40/92, DIN 50015; typical average values; test at 23°C

** - Cure 16 h at 104°F (40°C) or 20 min at 212°F (100°C); Test: 4 days in a conditioning chamber in 40/92 climate as specified by DIN 50015; Rating according to specified standard.

*** - Cure 20 min / 212°F (100°C); Mean static lap shear strength: 2364 psi (16.3 MPa); Test carried out using a load cycle frequency of 90 Hz.

Figure 1. Lap shear strength versus temperature (ISO 4587) (typical average values) Cure: (a) = 7 days at 73°F (23°C); (b) = 24 hours at 73°F (23°C) + 30 min / 176°F (80°C)

Safety & Health

- Safety Information

Keep out of reach of children

Packaging & Availability

- Regional Availability

- Packaging Information

Cartridges:

- 50 ml

- 200 ml

- 500 ml

Storage & Handling

- Storage Information

- ARALDITE® 2011 A/B Adhesive should be stored in a dry place, in the original sealed containers, at temperatures between 2°C and 40°C (36°F and 104°F). Under these storage conditions, the product has a shelf life of 6 years (from date of manufacture). The product should not be exposed to direct sunlight.

- If stored below 60°F, the adhesive should be brought to 60°F - 77°F and conditioned at this temperature for some time prior to use.

- Storage Conditions

ARALDITE® 2011 A/B should be stored in a dry place, in the original sealed containers, at temperatures between 2°C and 40°C (36°F and 104°F). Under these storage conditions, the product has a shelf life of 6 years (from date of manufacture). The product should not be exposed to direct sunlight. If stored below 60°F, the adhesive should be brought to 60°F - 77°F and conditioned at this temperature for some time prior to use.

Other

- Appearance

- Pale yellow

- Physical Properties

Value Units Test Method / Conditions Density approx. 1.05 g/cm³ g/cm³ Viscosity 30000.0-45000.0 cPs cPs at 25°C - Application Information

Value Units Test Method / Conditions Mix Ratio 0.8 %(W) %(W) Hardener : Resin