Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- 10-minute open time at RT

- Gap filling up to 30 mm

- Bright grey color (UV stable)

- Tolerant to ‘’less than ideal’’ pretreatment

- Tough flexible bonds for use in dynamic environments

- Product Features

- 10-minute open time at RT

- Gap filling up to 30 mm

- Bright grey color (UV stable)

- Tolerant to ‘’less than ideal’’ pretreatment

- Tough flexible bonds for use in dynamic environments

Applications & Uses

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Application Information

- Because of the high viscosity of the product, it is recommended to use a pneumatic dispensing gun.

- To ease the use with a manual dispensing gun, the cartridges can be preheated at 40°C during minimum 1 hour, if possible 2 hours before use.

- The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces.

- A layer of adhesive 0.25 mm thick will normally impart the greatest lap shear strength to the joint.

- The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

Properties

Technical Details & Test Data

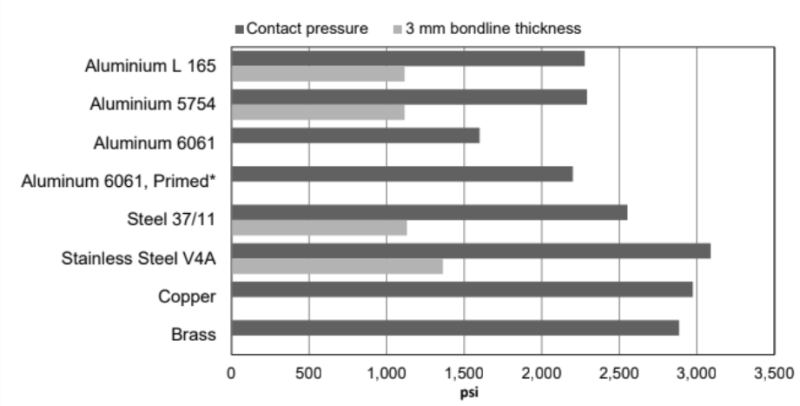

- Average Lap Shear Strength (ASTM D1002), Metal-metal Joints

- Substrates degreased with IPA.

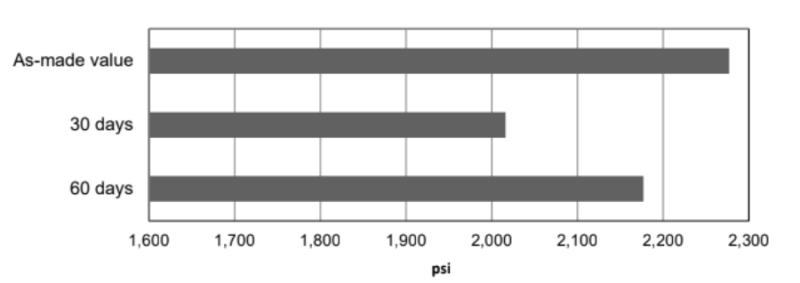

- Lap Shear Strength (ASTM D1002) versus Tropical Weathering (ISO 4587)

Lap shear strength (ASTM D1002) versus tropical weathering (ISO 4587) (typical average values) Aging at 40°C / 92% RH. Cure: 7 days at RT. Test at 23°C (73°F)

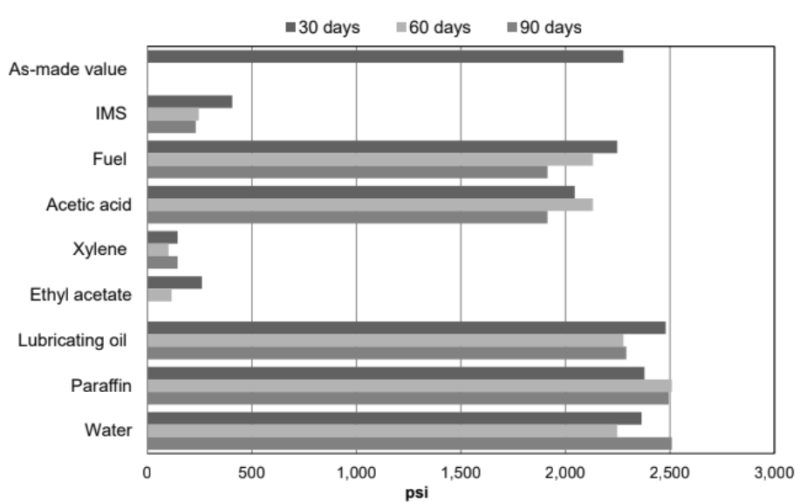

- Lap Shear Strength versus Immersion in various media (ASTM D1002)

Lap shear strength versus immersion in various media (ASTM D1002) (typical average values). Cured 7 days at RT Tested at 23°C (73°F). Lap Shear Strength was determined after immersion for 30,60 and 90 days at 23°C (73°F).

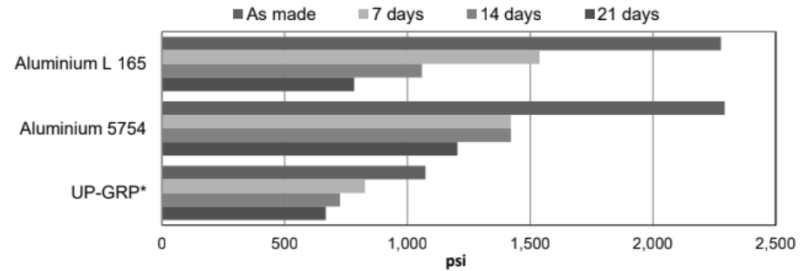

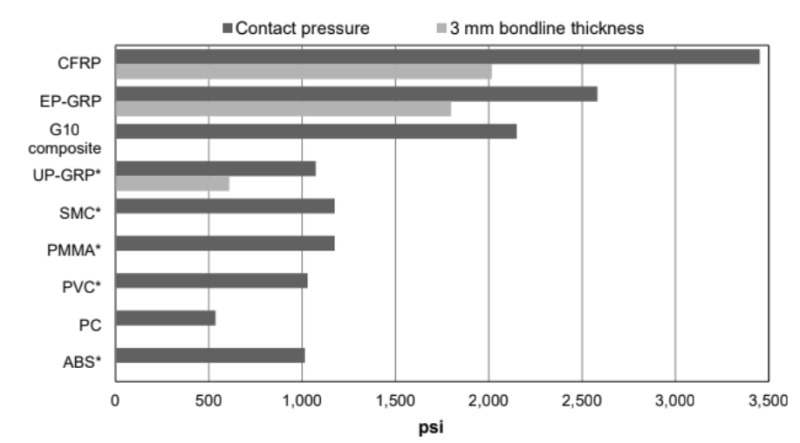

- Average Lap Shear Strength (ASTM D3163), Plastic-plastic Joints

Average lap shear strength (ASTM D3163), plastic-plastic joints. Substrates were lightly abraded and degreased with IPA.

- Technical Information

Pretreatment

- The strength and durability of a bonded joint are dependent on proper pretreatment of the surfaces to be bonded, however the methacrylate adhesives can be used effectively with little surface preparation.

- Ideally joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics) or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt.

- Low grade alcohol, gasoline (petrol) or paint thinners should never be used.

- The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces.

Equipment Maintenance

- All tools should be cleaned with hot water and soap before adhesives residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

- If solvents such as MEK are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

- Lap Shear Strength (ASTM D1002) versus Cataplasma ageing

- Cure 24 hours at 23°C (73°F) – per ISO 9142/E2.

- Tested at 23°C (73°F).

- Metals: sandblasted and degreased;

- Plastics: abraded and degreased.

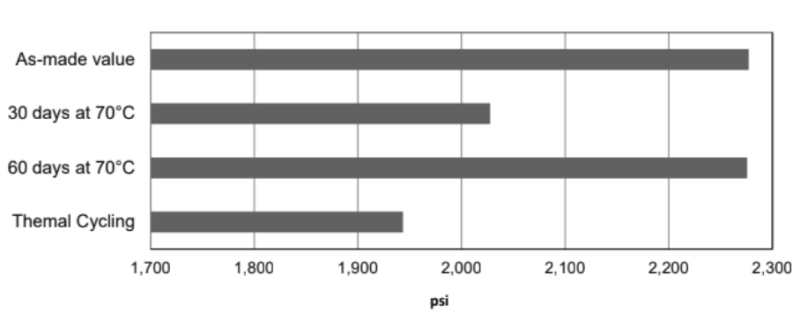

- Lap Shear Strength (ASTM D1002) versus Heat Ageing and Thermal Cycling

- Lap shear strength (ASTM D1002) versus heat ageing and thermal cycling (typical averagevalues).

- Cured 7 days at 23°C (73°F). Tested at 23°C (73°F).

- Thermal cycling 100 cycles: 2h at -30°C(-22°F) → 1 h ramp up to 70°C (158°F) → 2h at 70°C (158°F) → 1h ramp down to -30°C (-22°F))

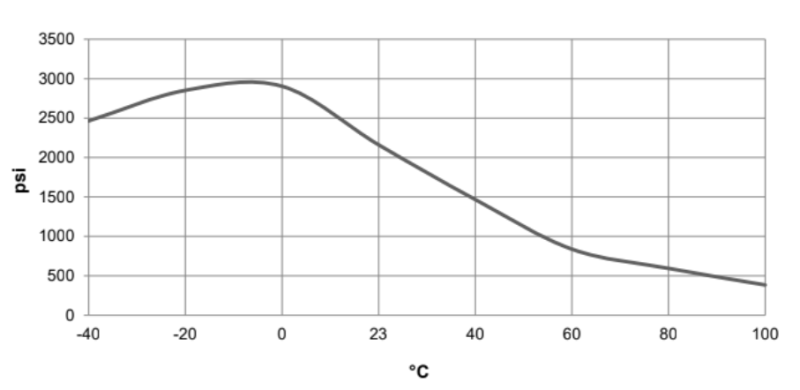

- Lap Shear Strength (ASTM D1002) versus Temperature

Lap shear strength (ASTM D1002) versus temperature (typical average values). On aluminium, pre-treatment: sand blasting. Cured 24 hours at 23°C (73°F).

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Storage Information

- ARALDITE® 2023-10 A/B Adhesive should be stored in a dry place, in the original sealed containers, at temperatures between 2°C to 8°C (36°F to 46°F).

- Under these storage conditions, the product has a shelf life of 24 months from date of manufacturing.

- The product should not be exposed to direct sunlight.

- The product may be placed at room temperature before use, the total time at room temperature should not exceed 6 months.

- Long term exposure above 25°C will reduce the shelf life of the product.

- The product should be never frozen.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.1 %(W) %(W) Hardener : Resin - Mechanical Properties

Value Units Test Method / Conditions Hardness 62.0 Shore D Shore D ISO 868 at 23°C Tensile Strength 22.0 MPa MPa ISO 527 at 23°C Tensile Strength 31.0 MPa MPa ISO 527 at 0°C Tensile Strength 3.0 MPa MPa ISO 527 at 100°C Tensile Strength 44.0 MPa MPa ISO 527 at -20°C Tensile Strength 54.0 MPa MPa ISO 527 at -40°C Tensile Strength 15.0 MPa MPa ISO 527 at 40°C Tensile Strength 11.0 MPa MPa ISO 527 at 60°C Tensile Strength 6.0 MPa MPa ISO 527 at 80°C - Physical Properties

Value Units Test Method / Conditions Density 1.29 g/cm³ g/cm³ ISO 1183 at 23°C, cured Glass Transition Temperature (Tg) 77.0 °C °C Dynamic Mechanical Analysis (DMA) Midpoint Storage Modulus Glass Transition Temperature (Tg) 46.0 °C °C Dynamic Mechanical Analysis (DMA) Storage Modulus Onset Lap Shear Strength 15.5 MPa MPa ISO 4587 at 23°C, on sandblasted aluminium 5754 Specific Gravity 1.09 -