Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Thixotropic – non slumping

- Toughened adhesive resilient bond

- Suitable for Metal and Composite bonding

- High shear and peel strength

Applications & Uses

- Application Method

- Compatible Substrates & Surfaces

- Markets

- Applications

- Processing Information

- Pretreatment: The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low-grade alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

Mix ratio Parts by weight Parts by volume Araldite® AV 4076-1 100 100 Hardener HV 5309-1 116 100 The resin and hardener should be blended until they form a homogeneous mix.

- Application of adhesive: The resin/hardener mix is applied with a spatula, to the pretreated and dry joint surfaces. A layer of adhesive 0.05 to 0.10mm thick will normally impart the greatest lap shear strength to the joint. The joint components should be assembled and clamped as soon as the adhesive has been applied. An even contact pressure throughout the joint area will ensure optimum cure.

- Mechanical processing: Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of adhesive. We will be pleased to advise customers on the choice of equipment for their particular needs.

- Equipment maintenance: All tools should be cleaned before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and,in addition, avoid skin and eye contact.

Times to minimum shear strength

Temperature °C 15 23 40 60 100 Cure time to reach Hours 10 6 2 - - LSS > 1N/mm² Minutes - - - 40 5 Cure time to reach Hours 20 14 4 - - LSS > 10N/mm² Minutes - - - 75 12

Properties

- Physical Form

Technical Details & Test Data

- Typical Cured Information

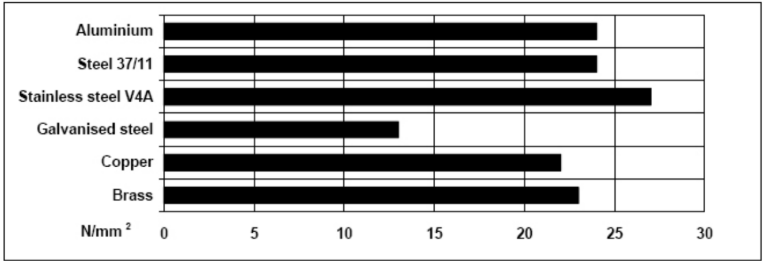

Average lap shear strengths of typical metal-to-metal joints (ISO 4587)

Cured for 16 hours at 40°C and tested at 23 °C. Pretreatment – Sand blasting

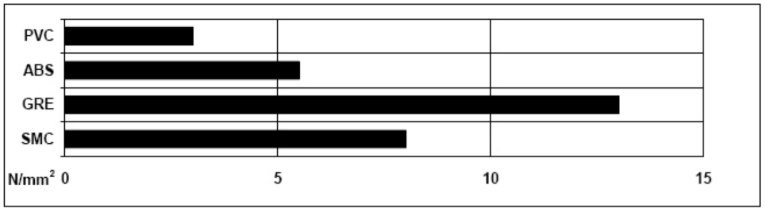

Average lap shear strengths of typical plastic-to-plastic joints (ISO 4587)

Cured for 16 hours at 40°C and tested at 23°C. Pretreatment – Lightly abrade and iso-propanol degrease.

Tensile strength at 23 °C (ISO 527) 20MPa

Tensile modulus : 1 GPa

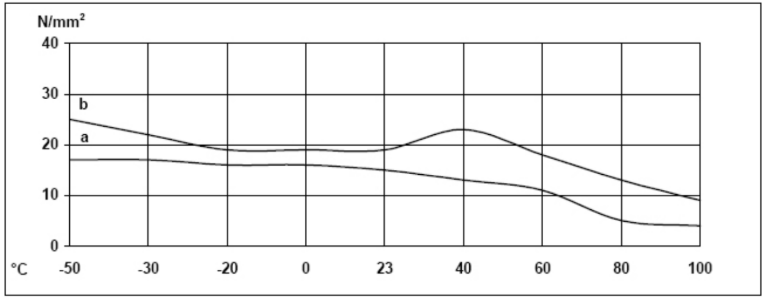

Elongation at break : 5 %Lap shear strength versus temperature (ISO 4587) (typical average values)

Cure: 24 hours at 23°C + 30 minutes at 80°C

(a) on GRE (b) on aluminium

Roller peel test (ISO 4587)

Cured 16 hours at 40°C : 4 N/mm

Glass transition temperature (DSC)

Cured 16 hours at 40°C : 64°C

Cured 4 hours at 60°C : 78°C

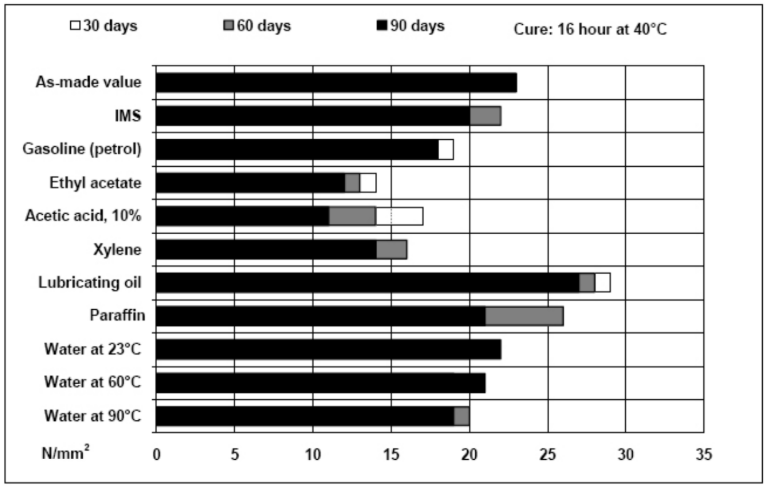

Lap shear strength versus immersion in various media (typical average values)

Unless otherwise stated, L.S.S. was determined after immersion for 90 days at 23°C

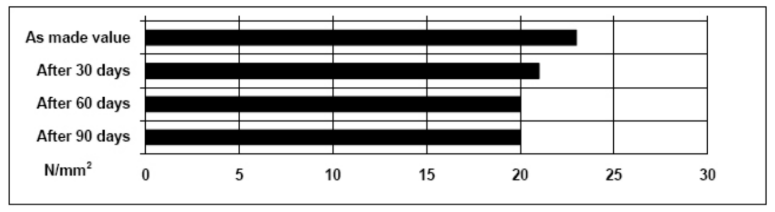

Lap shear strength versus tropical weathering

(40/92, DIN 50015; typical average values)

Cure: 16 hours at 40°C, tested at 23°C

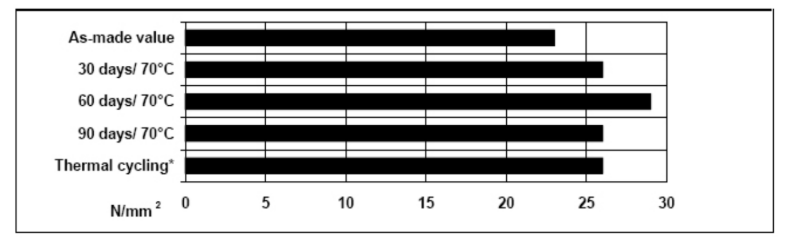

Lap shear strength versus heat ageing

Cure: 16 hours at 40°C

* 25 cycles -30°C to +70°C

Shear modulus (DIN 53445)

Cure: 48 hrs at 23°C plus 8 hrs at 60°C

Temperature (°C) Shear Modulus (G’) Unit 0°C 0.6 GPa 25°C 0.5 GPa 50°C 0.4 GPa 75°C 0.3 GPa 100°C 100 MPa 125°C 10 MPa

Storage & Handling

- Storage Conditions

ARALDITE AV 4076-1 and HARDENER HW 5309-1 should be stored in a dry place, in the sealed original container, at temperatures between +2°C and +40°C (+36°F and 104°F).Under these storage conditions, the shelf life is 3 years.The product should not be exposed to direct sunlight.

Other

- Appearance

- Neutral paste

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.16 %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity approx. 1.3 -