Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Properties

- Long useable life when mixed

- Resilient bond lines

- Good resistance to static and dynamic loadings

- Suitable for bonding non-ferrous metals and sandwich panels

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Applications

- The resin/hardener mix is applied with a spatula to the pretreated and dry joint surfaces.

- A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint.

- The joint components should be assembled and clamped as soon as the adhesive has been applied.

- An even contact pressure throughout the joint area will ensure optimum cure.

Properties

- Physical Form

Technical Details & Test Data

- Cured Properties

Typical cured properties

- Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lap- jointing 170 x 25 x 1.5 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

- The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification.

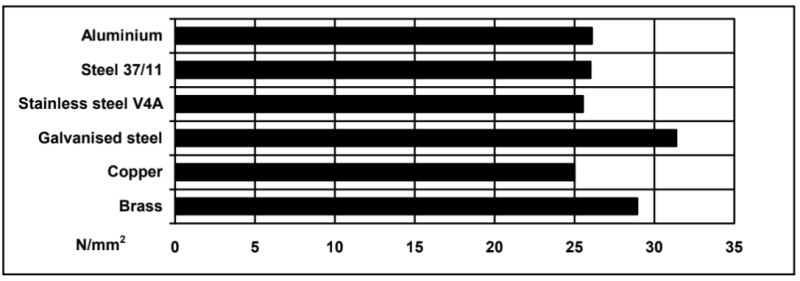

Average lap shear strengths of typical metal-to-metal joints (ISO 4587)

- Cure: 16 hours at 40°C and tested at 23°C

- Pretreatment - Sand blasting

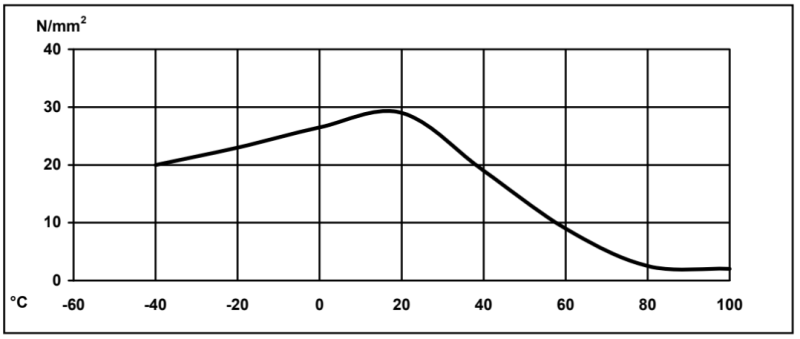

Lap shear strength versus temperature (ISO 4587) (typical average values)

- Cure: 16 hours at 40°C

Roller peel test (ISO 4578)

- Cure: 16 hours at 40°C : 4.5 N/mm

Electrolytic corrosion (DIN 53489)

- A-A/B 1,2 (4 days at 40°C/92% RH)

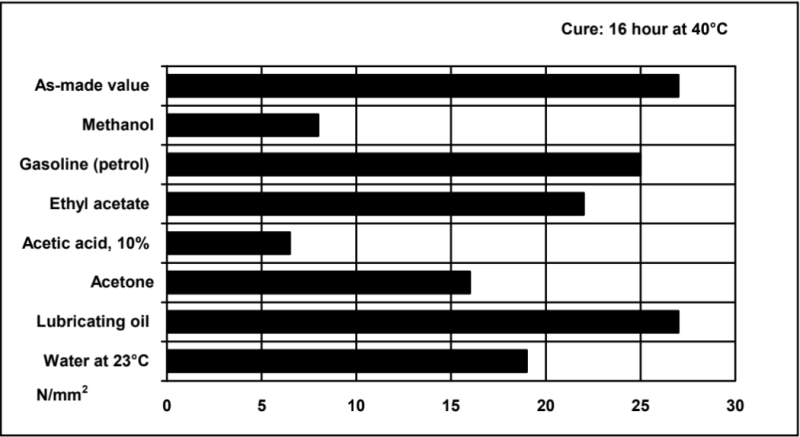

Lap shear strength versus immersion in various media (typical average values)

- Unless otherwise stated, L.S.S. was determined after immersion for 30 days at 23°C

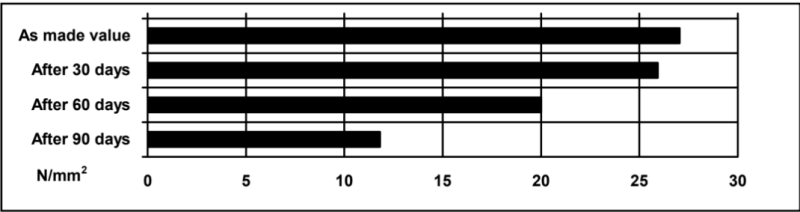

Lap shear strength versus tropical weathering

- (40/92, DIN 50015; typical average values)

- Cure: 16 hours at 40°C; test at 23°C

Fatigue test on lap joints (DIN 53285)

- Cure: 16 hours at 40°C; test at 95 Hz

- 30% of static failing load : 105 - 106 Cycles

- 20% of static failing load : 106 -107 Cycles

Shear modulus (DIN 53445)

Cure: 16 hours at 40°C

- 0°C - 2GPa

- 25°C - 1.1GPa

- 50°C - 0.1GPa

- 75°C - 3MPa

- 100°C - 2MPa

- Processing Information

Pretreatment

- The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded.

- At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprie-tary degreasing agents in order to remove all traces of oil, grease and dirt.

- Low grade alcohol, gasoline (petrol) or paint thinners should never be used.

- The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pick-ling”) the degreased surfaces.

- Abrading should be followed by a second degreasing treatment.

Mix Ratio Parts by weight Parts by volume

Araldite® AW 116 100 100 Hardener HV 953U 50 60 - Resin and hardener should be blended until they form a homogeneous mix.

Mechanical processing

- Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of adhesive.

- We will be pleased to advise customers on the choice of equipment for their particular needs.

Equipment maintenance

- All tools should be cleaned with hot water and soap before adhesives residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

- If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Curing times

Temperature (°C)

10 23 40 60 100 Cure Time (hours)

48 24 5 1 15 LSS at 23°C (N/mm²)

5 9 24 27 30 LSS = Lap shear strength.

Note - Curing below 10°C is unlikely to result in satisfactory performance.

Storage & Handling

- Storage and Handling Precautions

Storage

- Araldite® AW 116 and Hardener HV 953U may be stored for up to 6 years at room temperature provided the components are stored in sealed containers. The expiry date is indicated on the label.

Handling Precautions

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with food- stuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin.

- Adequate ventilation of the working area is recommended.

Other

- Appearance

- Beige

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.5 %(W) %(W) Hardener : Resin