Enhanced TDS

Identification & Functionality

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Properties

- Cures at room temperature

- Solvent free

- Good heat resistance

Applications & Uses

- Application Method

- Compatible Substrates & Surfaces

- Applications

- The resin/hardener mix is applied with a spatula to the pretreated and dry joint surfaces.

- A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint.

- The joint components should be assembled and clamped as soon as the adhesive has been applied.

- An even contact pressure throughout the joint area will ensure optimum cure.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Cured Properties

Typical cured properties

- Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lap- jointing 170 x 25 x 1.5 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

- The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification.

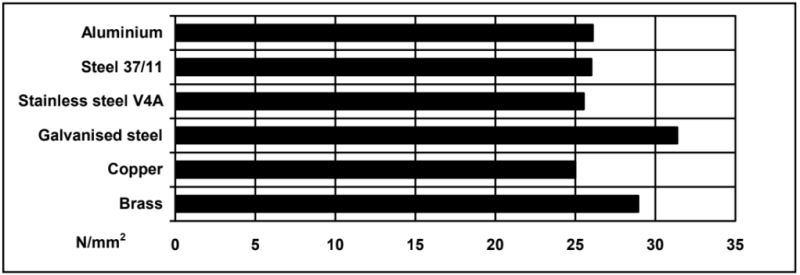

Average lap shear strengths of typical metal-to-metal joints (ISO 4587)

- Cure: 16 hours at 40°C and tested at 23°C

- Pretreatment - Sand blasting

- Processing Information

Pretreatment

- The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded.

- At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprie- tary degreasing agents in order to remove all traces of oil, grease and dirt. Low grade alcohol, gasoline (petrol) or paint thinners should never be used.

- The strongest and most durable joints are obtained by either mechanically abrading or chemically etching ( pickling ) the degreased surfaces.

- Abrading should be followed by a second degreasing treatment

Property

Parts by Weight

Parts by Volume

Araldite® AW 134 100 100 Hardener HY 991 30 40 Resin and hardener should be blended until they form a homogeneous mix.

Mechanical processing

- Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of adhesive.

Equipment maintenance

- All tools should be cleaned with hot water and soap before adhesives residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

- If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Curing times

Temperature (°C) 10 23 40 60 100 Cure Time (hours) 24 24 3 - - Cure Time (minutes) - - - 30 10 LSS at 23°C (N/mm²) 10 - 12 13 - 15 15 - 17 15 - 17 19 - 21 LSS = Lap shear strength.

Storage & Handling

- Storage and Handling Precautions

Storage

- Araldite® AW 134 and Hardener HY 991 may be stored for up to 6 years at room temperature provided the components are stored in sealed containers.

Handling Precautions

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with food- stuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin.

- Adequate ventilation of the working area is recommended.

Other

- Appearance

- Grey

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.3 - Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity approx. 1.2 - Viscosity approx. 25.0 Pa.s Pa.s