Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Resin and hardener components are easily processed liquids

- Rapid gelation at mold temperatures of 140C and above

- Excellent mechanical and electrical properties

- Excellent fracture toughness characteristics

- Excellent performance in applications requiring thermal cycling

- Recognized insulation component with Thermal Index of 200C

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Processing Information

- Araldite® CW 229 US Resin and Aradur® HW 229-1 US Hardener system is ideally suited for processing by conventional techniques. The optimum gelation and cure schedule in this case is dependent on the design of the part. When casting very large parts with this system, an extended cure cycle is recommended to reduce formulation of high stress areas within the cured part. General processing conditions are given below:

- Smaller parts: For relatively thin, low mass castings, a simplified cure schedule would be: within preheated mold at 80oC - 100°C, mix materials at 40oC - 80°C. Fill mold, then gel typically for 4 - 6 hours at 80°C or 2 hours at 100°C. Then post cure either 2 hours at 140°C, or 10 hours at 130°C.

- Very large parts: Within preheated mold and mixed materials at 60oC - 80°C, cure with either a step or ramp cure cycle. For example, ramp cure from initial mold temperature to 140°C in linear ramp over a time of 16 - 24 hours. Then post cure for an additional 4 - 6 hours at 140°C. Cool slowly to 100°C or less over a period of several hours prior to de-molding.

- APG Casting: This system is ideally suited to processing by the Automatic Pressure Gelation (APG) technique. However, it can be used to produce small sized castings by conventional means as above. In using the APG process, preheat mold to 140oC - 160°C. Fill the mold in 2 - 5 minutes with the mixed material at 50°C to 60°C. Gel within mold under pressure of 1 - 3 atm for 7 - 15 minutes (dependent on part size and mixed material temperature). Then post cure for either 2 hours at 150°C, 4 - 6 hours at 140°C, or 10 hours at 130°C.

Properties

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Typical Electrical Properties

Typical Electrical Properties

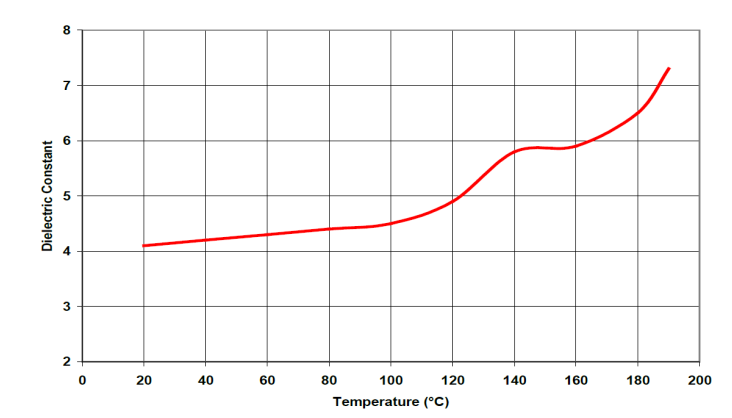

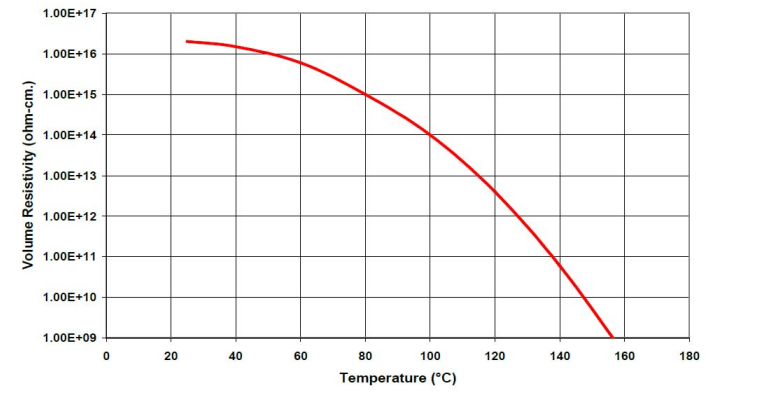

Dielectric strength (at 3 mm) 420 - 480 V/mil IEC 60243 Dielectric constant Figure 2 - IEC 60250 Dissipation factor Figure 3 - IEC 60250 Volume resistivity Figure 4 ohm-cm IEC 60093 Thermal endurance Figures 5 & 6 - IEC 216 Figure 2. Dielectric constant vs. temperature at 60 Hz

Figure 3. Dissipation factor vs. temperature at 60 Hz

Figure 4. Volume resistivity vs. temperature

- Typical Physical Properties

Typical Physical Properties

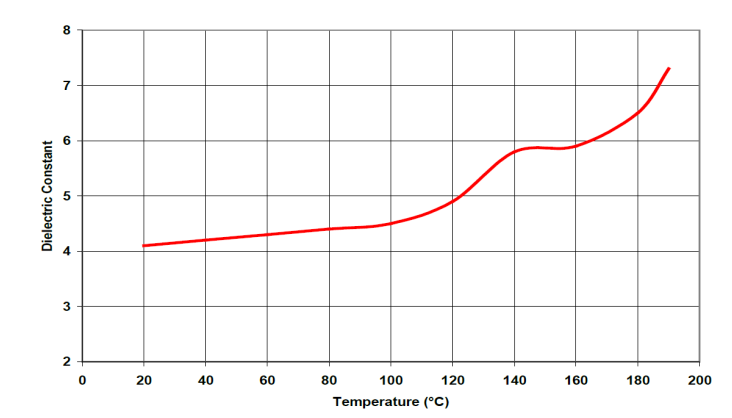

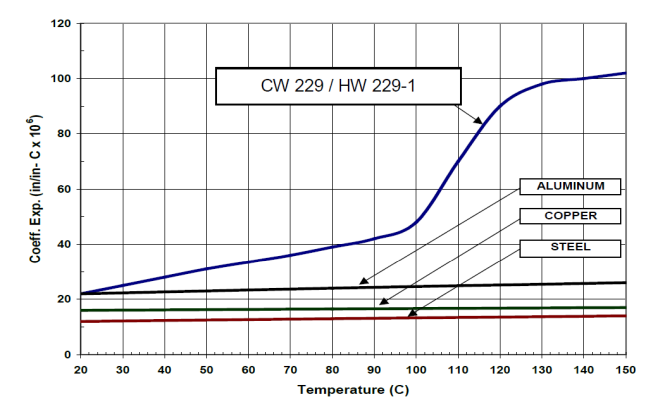

Tensile strength 11,000 - 12,500 psi ASTM D638 Elongation at break 0.80 - 1.20 % ASTM D638 Tensile modulus (1.50 - 1.55) x 10⁶ psi ASTM D638 Flexural strength 18,000 - 19,000 psi ASTM D790 Flexural modulus (1.40 - 1.50) x 10⁶ psi ASTM D790 Hardness 92 - 96 Shore D - Glass transition temperature 110 - 120 °C DSC Coefficient of thermal expansion Figure 1 ppm/°C TMA Water absorption (24 hours at 23°C) 0.020 - 0.025 % ASTM D 570 Thermal conductivity 0.7 - 0.8 W/m·K ISO 8894-2/90 Density 1.81 - 1.85 g/cm³ ASTM D792 Thermal endurance Figures 5 & 6 - UL 746B Critical stress intensity factor (K1C) 2.8 - 3.0 MPa·m¹/₂ Double Torsion Test Specific energy at break (G1C) 740 - 790 J/m² Double Torsion Test Figure 1. Coefficient of Thermal Expansion as a function of temperature

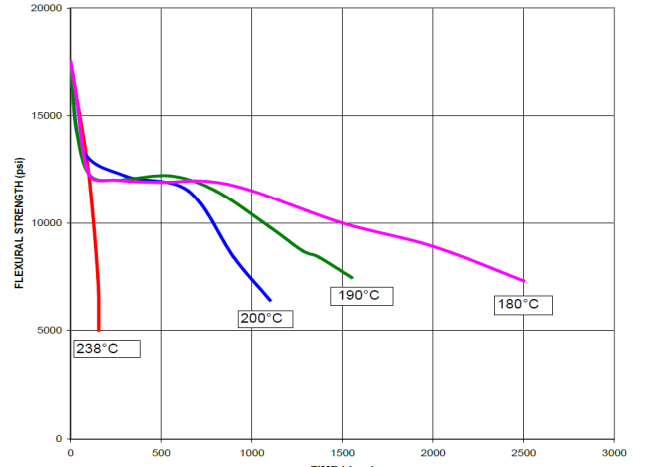

Figure 5. Thermal endurance

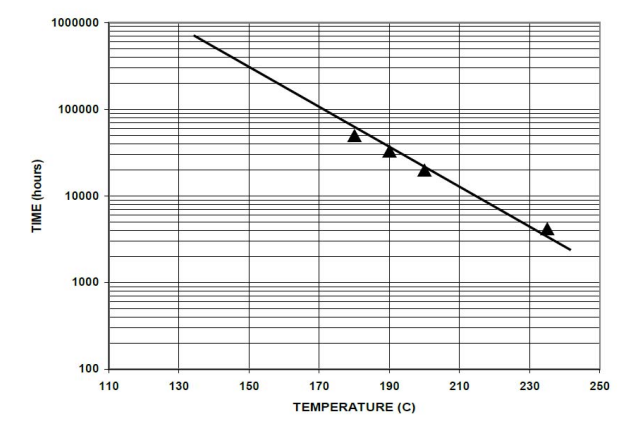

Figure 6. Thermal endurance - 50% Flexural strength

Storage & Handling

- Storage Conditions

- Araldite® CW 229 US Resin contains some curing catalyst and / or accelerator. It should preferably not be stored for long periods at temperatures exceeding 30°C nor should it be exposed to temperatures in excess of 100°C for more than 2 hours. Incorrect handling will result in an increase in viscosity and reduced performance properties of the cured system.

- Aradur® HW 229-1 US Hardener contains some curing catalysts and / or accelerators. Storage at elevated temperatures (>80°C) for extended periods (e.g. >5 days) will result in an undesirable increase in viscosity and impaired reactivity of the mixed system. This hardener is sensitive to moisture. Partially used containers should be closed immediately after use. Nitrogen blanketing is highly recommended as well as the use of a desiccant venting device unless the material is going to be used rapidly after opening.

- Araldite® CW 229 US Resin and Aradur® HW 229-1 US Hardener should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 1 year (from date of manufacture). The product should not be exposed to direct sunlight. As with most pre-filled systems, the fillers present in these components have a tendency to separate during storage. This filler separation will not negatively affect the final product properties and quality provided that both components are thoroughly homogenized. The filled components should be stirred carefully by using a low shear mixer prior to processing. Do not use high speed or high shear mixers and take precautions to prevent air entrapment.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Glass Transition Temperature (Tg) 110.0-120.0 °C °C Viscosity 35000.0-65000.0 cPs cPs at 25°C, mixed