Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Features

- Low viscosity for good penetration

- Bonds well to most substrates

- Adequate working life at room temperature

- Rapid cure at moderately elevated temperatures

- Moderate glass transition temperature

- Very low shrinkage upon cure

- Excellent dielectric properties

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

Technical Details & Test Data

- Processing Guidelines

Recommended cure time: 12 hours at 23°C + 3 hours at 95°C

Gel time at 2°C (120 grams), minutes : 170 - 220

Gel time at 40°C (10 grams), minutes : 100 - 150

Gel time at 60°C (10 grams), minutes : 30 - 35- Physical Properties

Cure: 12 hr/23°C + 3 hr/95°C

Flexural strength, psi

9,000 - 12,000

Flexural modulus, psi

520,000 - 540,000

Hardness, Shore D

78 - 84

Glass transition temperature, C

90 - 95

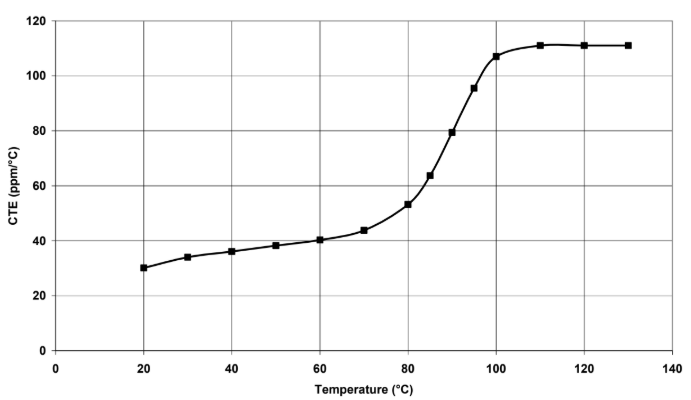

Coeff. thermal expansion, in/in-C

see Figure 2

Linear Shrinkage, %

Less than 0.005 inches/inch

Figure 2

Cure: 12 hours at 23°C + 3 hours at 95°C

- Electrical Properties

Cure: 12 hr/23°C + 3 hr/95°C

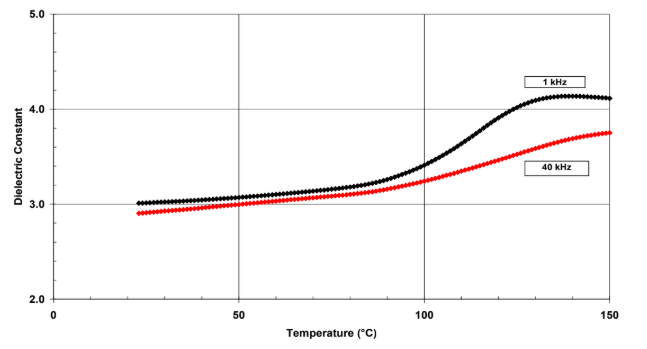

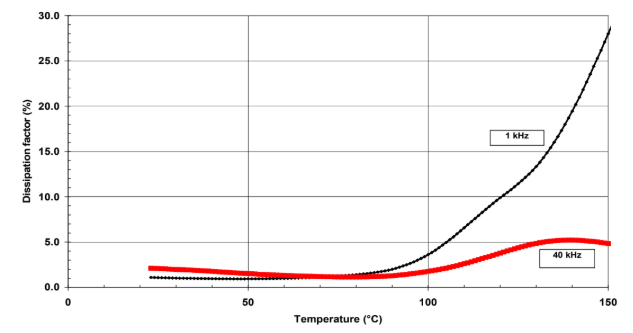

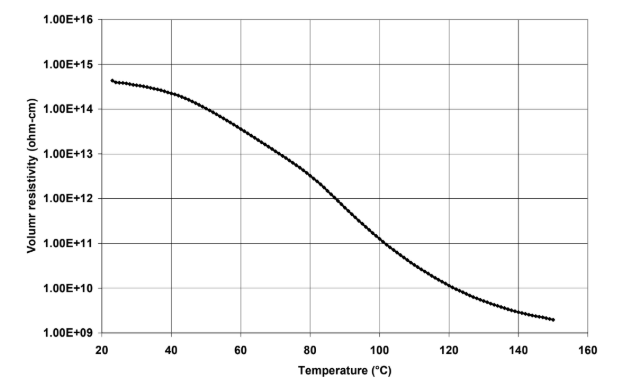

Dielectric strength, kV/mm at 2 mm. thickness 27.9 Dielectric constant see Figure 3 Dissipation factor see Figure 4 Volume resistivity see Figure 5 Surface resistivity see Figure 6 Figure 3

Dielectric Constant vs. Temperature

Figure 4

Dissipation Factor v. Temperature

Figure 5

Volume Resistivity vs. Temperature

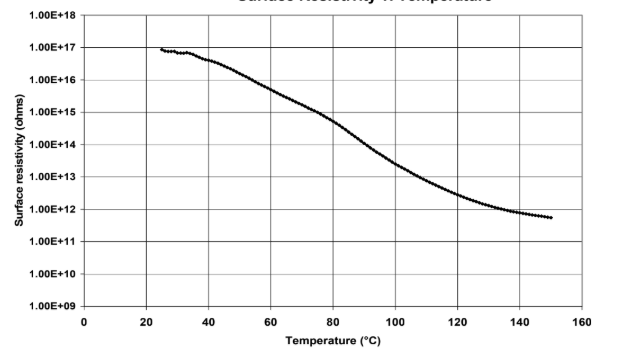

Figure 6

Surface Resistivity v. Temperature

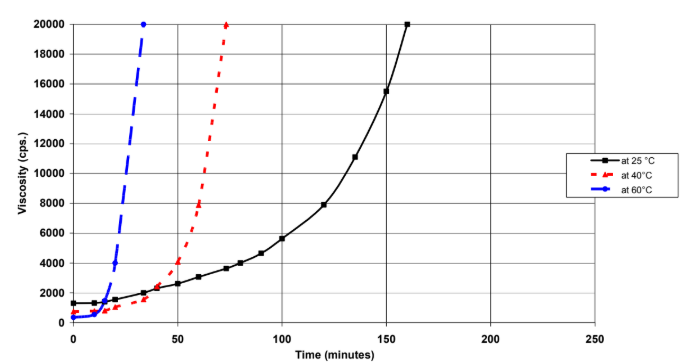

- Viscosity vs Time Graph

Storage & Handling

- Storage Conditions

Araldite® CW 5801-1/Aradur® HY 5801 components should be stored in a dry place and in the sealed original containers at temperatures between 2°C and 40°C (36°F and 104°F). Under these storage conditions the shelf life for each product is 1 year. The products should not be exposed to direct sunlight. Some filler separation may occur in the Araldite® CW 5801- 1 component during storage. Prior to use it should be re-homogenized by gentle stirring to prevent air entrapment.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.196 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity 0.79-0.84 - Viscosity 1100.0-1300.0 cPs cPs at 25°C Viscosity 700.0-750.0 cPs cPs at 40°C Viscosity 350.0-400.0 cPs cPs at 60°C