Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials,Binder & Resin

- Single Ingredient

- Yes

- Technologies

- Product Families

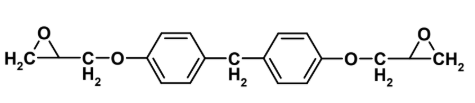

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Features and Benefits

- Low viscosity

- Higher functionality than bisphenol A epoxy resins

- Excellent chemical resistance

- Outstanding resistance to solvents

- Excellent mechanical properties

- Good flexibility

Applications & Uses

- Applicable Processes

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Composites End Use

- Composites Processing Methods

- Industrial Additives End Use

- Markets

- Applications

- Application Details

ARALDITE® GY 285, alone or blended with epoxy resins based on bisphenol A or bisphenol A / F in combination with polyamine hardeners, is recommended for solvent-free coatings, impregnation, floorings and trowelling compounds applied to steel and concrete substrates

- Advanced composite structures

- Adhesives

- Resin transfer moliding

- Filament winding

- Product Application

Very low viscosity bisphenol F epoxy resin. For use in coatings, adhesives, composites and castings.

Properties

- Physical Form

Regulatory & Compliance

Safety & Health

- Safety Precautions

- Avoid contact with eyes, skin or clothing.

- Avoid breathing vapor-mist or spray.

- Use with good ventilation.

- Wash after handling.

- Store in a cool, dry area in closed containers.

- In case of contact :

- Eyes : Immediately flush with water for at least 15 minutes.

- Skin : Promptly wash thoroughly with mild soap and water.

- Inhalation : Remove to fresh air. Give oxygen if breathing is difficult.

- Ingestion : In conscious, give plenty of water and get immediate medical attention

Packaging & Availability

- Regional Availability

- Packaging Information

It can be purchased in 484 pound drums.

Storage & Handling

- Storage Information

ARALDITE GY 285 has a shelf life of five years when stored in a dry place in the well-closed original container at 18 - 25°C.

Other

- Appearance

- Clear, no contamination

- Color (SDS)

- Light yellow

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slight

- Physical Properties

Value Units Test Method / Conditions Density 1.19 g/cm³ g/cm³ At 25°C Flash Point min. 93.0 °C °C Closed Cup Flash Point min. 200.0 °C °C Viscosity 2000.0-3000.0 - At 25°C