Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Properties

- Low viscosity and good impregnation capability

- Solvent free and free of foaming agent

- Long pot-life, low exotherm, suited for large bushings

- Permanent elastic, mechanically strong, good adhesion

- Temperature range -60 °C to 120 °C

- Low dielectric losses

- No filler, no sedimentation

- Cures at 8 °C

- Low water absorption

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Processing Information

Preparation of parts

-

The parts, which are to be casted, should be dry, clean and free of greases.

- Preheating is not necessary, best temperature range for processing is between 18 and 40 °C, it also works at temperatures down to 8°C.

Mixing and Injection

-

Polyol and Isocyanate are mixed according to the specified mix ratio using preferably a two component metering and mixing machine.

- High speed mixing head is preferred.

- The foaming gas is injected during mixing at elevated pressure.

- Molds to be filled preferably from the bottom side. Heights of several meters are possible.

Variation of mix ratio and effect on final properties

Mix ratio pbw 100/ 23 100/ 25 100/ 27 Shore A 30 42 47 Shore D 5 9 11 - - - Regular ratio - Gel Time, Viscosity and Curing

Mix Viscosity at 25°C Rheomat mPa.s 2100 - 2600 Pot life at 25°C

(Time to reach 5000 mPa.s)Rheomat min 40 (Time to reach 15000 mPa.s) Rheomat min 120 - Rheomat min 38 Geltime at 25 °C Gelnorm min 245 Geltime at 40 °C Gelnorm min 158 Geltime at 60 °C Gelnorm min 89 Geltime at 80 °C Gelnorm min 50 Cure Times

Minimum Curing Cycle: 72 hours at RT or Cure at max. 60°C possible 6 h 60°C

Mechanical and Physical Properties

System tested:

Arathane CY 11035-1 / HY 11036 = 100 / 25 pbw, in bulk, not foamed

Determined on unreinforced, cast standard test specimen at 23°C

Cured for 72 h at 23°CTensile strength ISO 527 MPa 2 - 3 Elongation at break ISO 527 % 150 - 250 E modulus from tensile test ISO 527 MPa 0.5 - 1 Flexural strength ISO 178 MPa 0.2 - 0.4 Elongation at break ISO 178 % 12 - 17 E modulus from flexural test ISO 178 MPa 1 - 2 Shear Modulus, DMA ISO 6721 MPa 6 - 7 Glass transition temperature (DSC) ISO 11357-2 °C - (60 - 70) Coefficient of linear thermal expansion ISO 11359-2 ppm / K appr. 80 Mean value for temperature range: below -65°C Thermal conductivity similar to ISO 8894-1 W/mK 0.19 - 0.2 Water absorption (specimen: 50x50x4 mm) 10 days at 23°C ISO 62 % by wt. 0.32 - 0.40 30 min at 100°C ISO 62 % by wt. 0.55 - 0.65 Density at 25°C ISO 1183 g/cm³ 1.15 - 1.20 FOAM density at 25 °C typical g/cm³ 0.35 - 0.40 Electrical Properties

System tested:

ARATHANE® CY 11035-1 / ARATHANE® HY 11036 = 100 / 25 pbw, in bulk, not foamed

Determined on unreinforced, cast standard test specimen at 23°C

Cured for 72 h at 23°C

- Breakdown strength IEC 60243-1 kV/mm 20 - 23

- Tracking resistance IEC 60112 with test solution A CTI > 600 - < 1mm

- Tracking resistance with test solution B CTI > 600M - < 1mm

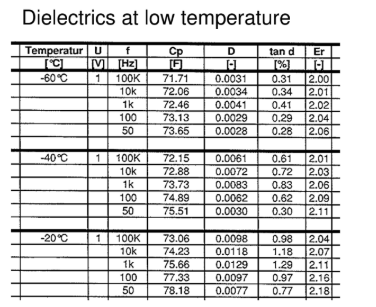

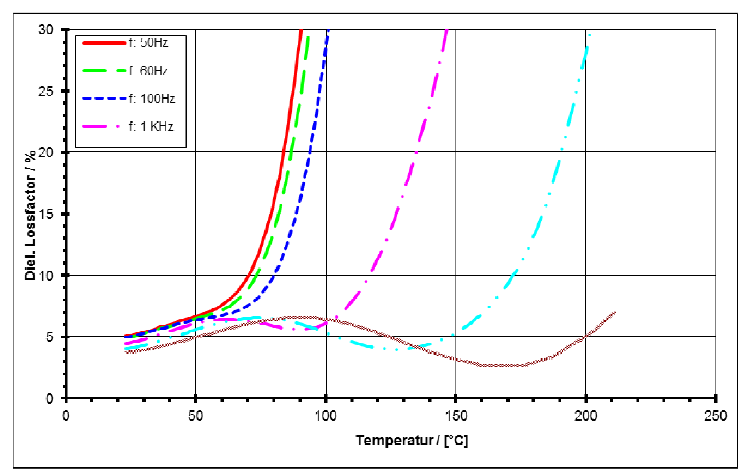

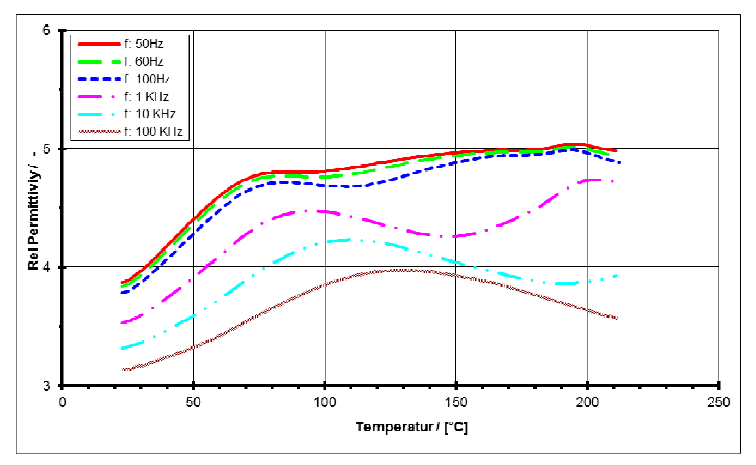

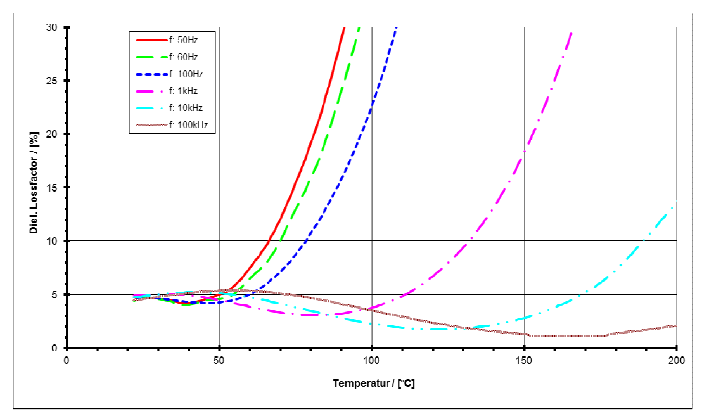

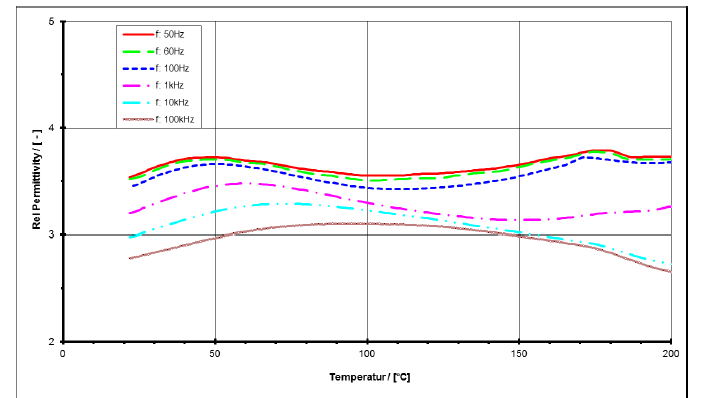

Loss factor (tan delta) and dielectric constant (er) as a function of temperature

(measurement frequency: 50 Hz – 100 kHz)(IEC 250 / DIN 53483)

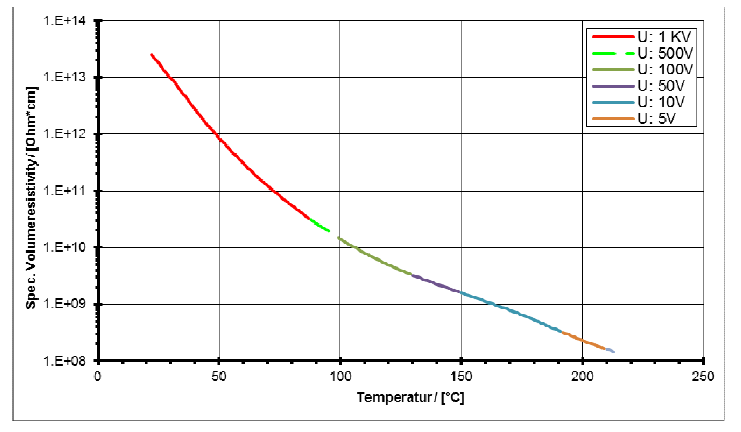

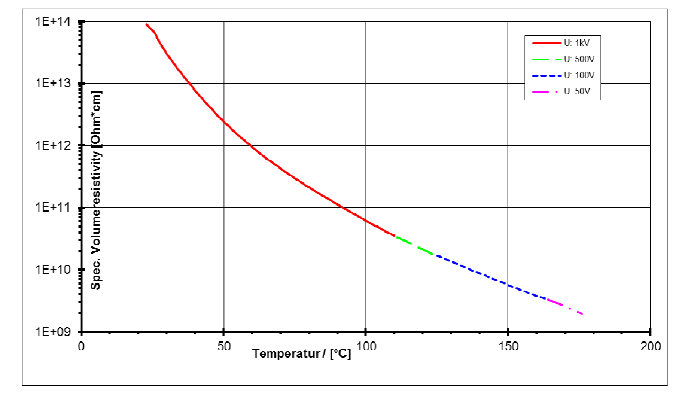

Volume resistivity as a function of temperature (measurement voltage: 1000 V) (IEC 93 / DIN 53482)

FOAM tested:

Mechanical and Physical Properties

System tested:

ARATHANE® CY 11035-1 / ARATHANE® HY 11036 = 100 / 25 pbw as a foam

Flow rate on casting: ca. 120 ml/sec; 0.7 Liter /min

Blowing gas: Nitrogen

Spec. Weight of the specimen: 0.392 g/cm3; appr. 66% gas N2 in Foam

Closed cell foam, pore diameter < 1 mm

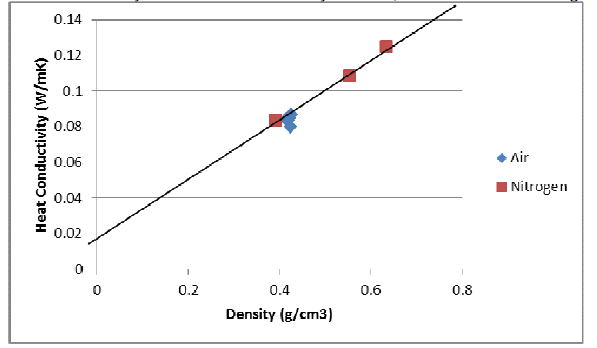

Note: Determined on foamed, cast standard test specimen at 23°C Cured for 72 h at 23°CFlexural strength ISO 178 MPa 0.1 - 0.3 Elongation at break ISO 178 % 12 - 17 E modulus from flexural test ISO 178 MPa 1 - 2 Glass transition temperature (DSC) ISO 11357-2 °C - (65 - 70) Density at 25°C in bulk: ISO 1183 g/cm³ 1.15 - 1.20 FOAM density at 25 °C - g/cm³ 0.35 - 0.40 Water absorption (specimen: 50x50x4 mm) ISO 62 10 days at 23°C - % by wt. 1.00 - 1.10 Heat conductivity as a function of density of foam, made with air or nitrogen

Standard ISO 8894-2/07 (GLOW WIRE METHOD)

Specimen: 100X50X10 mm (directly casted into mould), made in Huntsman LabsSystem tested:

ARATHANE® CY 11035-1 / ARATHANE® HY 11036 = 100 / 25 pbw, as a foam

Determined on foamed, cast standard test specimen at 23°C

Cured for 72 h at 23°CBreakdown strength IEC 60243-1 kV/mm 10 - 14

Loss factor (tan delta) and dielectric constant (er) as a function of temperature (measurement frequency: 50 Hz – 100 kHz)(IEC 250 / DIN 53483)

Volume resistivity (r) as a function of temperature (measurement voltage: 1000 V) (IEC 93 / DIN 53482)

Note:

- CY 11035 /HY 11036 is the precursor of the actual system, based on ARATHANE® CY 11035-1 / ARATHANE® HY 11036

- The technical difference is not significant.

- One component of Polyol CY 11035 was no more available, a slight change to CY 11035-1 could not be avoided.

Processing methods: Casting with gas injection

-

Packaging & Availability

- Packaging Information

- ARATHANE® CY 11035-1 180KG Q4E

- ARATHANE® HY 11036 25KG Q4E

Storage & Handling

- Storage Conditions

- Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- After this date, the product may be processed only after reanalysis.

- Partly emptied containers should be tightly closed immediately after use.

- ARATHANE® HY 5610 must be protected from moisture. Storage tanks should be blanketed with dry air or nitrogen.

- Storage at temperatures above 50°C is not recommended, since this can lead to the formation of insoluble solids and also the viscosity build-up increases on extended storage. Storage at low temperature is not recommended because it may lead to some crystallization.

- Crystallized material must be melted out immediately by short time heating.

- For information on waste disposal and hazardous products of decomposition in the event of a fire, refer to the Material Safety Data Sheets (MSDS) for these particular products.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.25 - Hardener : Resin