Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Blend

- No

- Carrier

- Chemical Family

- Chemical Name

- Function

- Etchant

- Industrial Additives Functions

- Product Functions

- Single Ingredient

- No

- Technologies

- Product Families

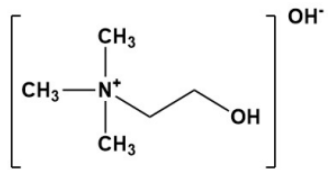

- Chemical Structure

Features & Benefits

- Base Chemicals Features

- Industrial Additives Features

- Product Highlights

E-GRADE® Choline Hydroxide is a clear aqueous solution with a high pH and a mild odor. It has been found to have a very low corrosion rate to copper and other metallic surfaces and has been demonstrated to effectively remove both positive and negative photoresists.

The product is an effective replacement for TMAH and is available in higher concentrations than TMAH in both water and organic solvents (R&D). The combination of low corrosion rates, photoresist removal, etching, and lower toxicity make E-GRADE® Choline Hydroxide an effective, safer to handle alternative to TMAH in next generation semiconductor cleans with performance enhancements such as faster photoresist removal rate and selective metal removal rates.- Product Benefits

- Organic base

- High purity, low trace metal

- Available at 45 wt%

- Water or solvent based

- TMAH replacement

- Developer, stripper, and PERR

- Etching agent

- CMP slurries and pCMP Cleans

- Water soluble

- Low Viscosity

Applications & Uses

- Applicable Processes

- Base Chemicals End Uses

- Compatible Substrates & Surfaces

- Industrial Additives End Use

- Markets

- Applications

- Product Applications

- E-GRADE® Choline Hydroxide can be used as a developer, etchant and cleaning agent in electronics applications.

- Typically it will be blended with other chemicals into a formulated product for a particular application.

- E-GRADE® Choline Hydroxide has been found to have a very low corrosion rate to copper alloy although it is corrosive to aluminum alloy.

- E-GRADE® Choline Hydroxide is an effective replacement to tetramethylammonium hydroxide (TMAH) with regard to performance and, because it is not in the same toxicity category as TMAH, it is considered to be saler to use.

Properties

- Physical Form

- Note

*-Thickness measured with Napson Cresbox 4 point-probe tester and Filmetrics.

Regulatory & Compliance

Technical Details & Test Data

- TMAH Analysis

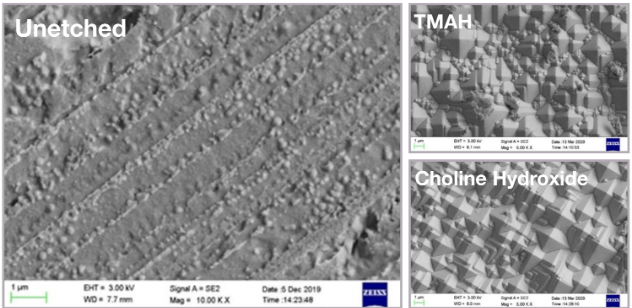

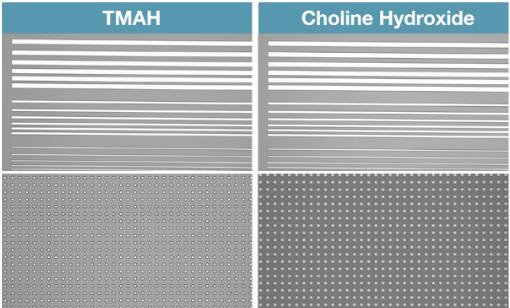

Silicon wafers, etched with E-GRADE® Choline Hydroxide, demonstrate significant reductions in reflectivity and improvement in uniformity when compared to wafers treated with TMAH. This texturization reduces light reflection and improves absorption for photovoltaic devices.

Positive tone Novolak photoresist is well developed at room temperature with E-GRADE® Choline Hydroxide.

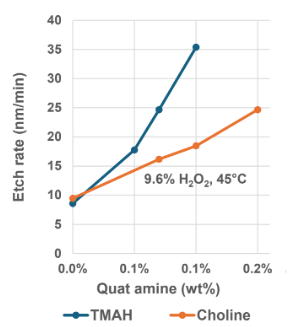

- TiN Etch with Hydrogen Peroxide Curve

H₂O₂ (wt%) Quat pH at 45°C TiN (nm/min) Cu (nm/min) H₂O₂ degradation (%/hr)

8.00% TMAH 7.96 18.67 -0.31 0.071 8.00% COH 8.05 19.02 0.39 0.058 9.60% TMAH 8.07 33.3 0.66 0.148 9.60% COH 8.03 24.66 0.47 0.098 At proper pH and concentration, E-GRADE® Choline Hydroxide with H2 O2 can be used for TiN etch (etch rate > 20 nm/min). The degradation rate of H2 O2 with Choline Hydroxide was observed to be much slower than with TMAH. Degradation rate is based on 24 hr average at 45°C.

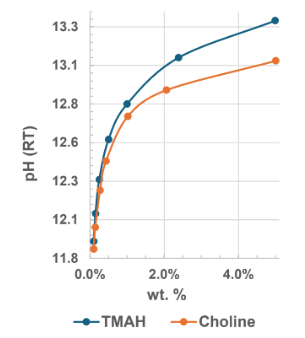

- pH-Concentration Dependence Curve

Concentration dependence of pH values for TMAH and Choline in water.