Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

- Meets FST requirements

- Quick setting

- High mechanical performance

- Can be dispensed by meter mix machines

- Easy to apply and clean

- Qualified to BMS5-28 Type 18 Class 1

- No SVHC as defined under REACH

- Increase productivity by up to 50% with EPOCAST® 1648 A/B void filler. Available in bulk packaging for meter-mix dispensing or in cartridges, it can be applied faster than traditional mixing and application methods. It also sets quickly at room temperature so parts can move through production quicker. This low-density FST void filler can save weight in higher load applications, with up to a 40% improvement in compressive strength compared to competitive products. EPOCAST® 1648 A/B void filler is qualified to Boeing BMS 5-28, Type 18, Class 1 and De Havilland DHMS P1.30 Grade 2.

- Features and Benefits

- Meets FST requirements

- Quick setting

- High mechanical performance

- Can be dispensed by meter mix machines

- Easy to apply and clean

- Qualified to BMS5-28 Type 18 Class 1

- No SVHC as defined under REACH

Applications & Uses

- Application Area

- Markets

- Applications

- Application Information

EPOCAST® 1648 A/B is suitable for aerospace application, requiring high strength and low density, such as fastener potting, edge filling / sealing, ditch pot fold, tab / slot joining, and honeycomb core reinforcing.

- Application Information

Epocast® 1648 A/B low density epoxy adhesive is suitable for aerospace application, requiring high strength and low density, such as fastener potting, edge filling / sealing, ditch pot fold, tab / slot joining, and honeycomb core reinforcing.

Properties

- Physical Form

- Notes

↑ - Hot / Wet exposure: 7 days at 25℃ (77°F) followed by 14 days at 71°℃ (160°F) /95% relative humidity.

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

Technical Details & Test Data

- Technical Information

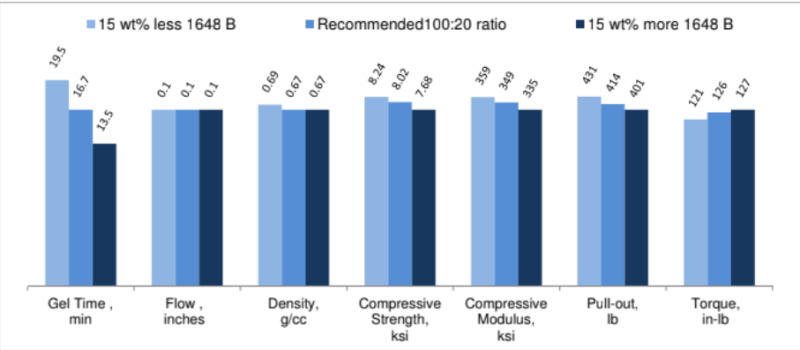

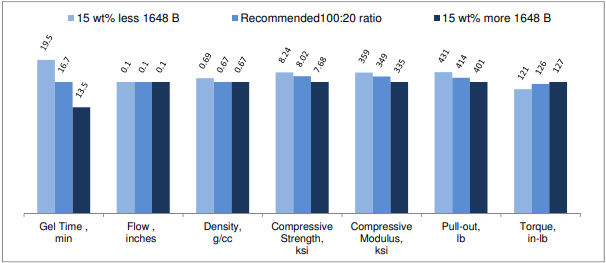

Mix Ratio Tolerance

- While the below chart shows that small mix ratio deviations occurring during the processing of Epocast® 1648 A/B will have a minimal impact on the system performance properties, the system will only perform optimally when used at the recommended mix ratio.

- Effect of Mix Ratio on Flammability

Property Value Unit Condition Extinguish Time max.1.0 sec for 15 wt% less 1648B, 100:20 ratio, 15 wt% more 1648B

Burn Length 0.2 inch for 15 wt% less 1648B Burn Length 0.3 inch for 100:20 ratio Burn Length 0.3 inch for 15 wt% more 1648B Drip Extinguishing Time No drip - for all ratios - Typical Physical After Cure Properties

Property Value Unit Test Method Condition Density 0.66 - 0.70 g/cm³ ASTM D1622 - Compressive Strength 6500 - 8000 psi ASTM D695 at 73°F (23°C) Compressive Strength 6670 - 6830 psi ASTM D695 after 7 days at 25°C (77°F) followed by 14 days at 71°C (160°F) / 95% relative humidity, at 73°F (23°C)

Compressive Modulus 300 - 400 ksi ASTM D695 at 73°F (23°C) Compressive Modulus 280 - 300 ksi ASTM D695 after 7 days at 25°C (77°F) followed by 14 days at 71°C (160°F) / 95% relative humidity, at 73°F (23°C)

Tensile Lap Shear Strength 1900 - 2200 psi ASTM D1002 at 73°F (23°C), Al-Al Tensile Lap Shear Strength 1890 - 2010 psi ASTM D1002 after 7 days at 25°C (77°F) followed by 14 days at 71°C (160°F) / 95% relative humidity, at 73°F (23°C), Al-Al

Insert Pull-out Strength 350 - 450 lb OEM - Insert Torque Strength 100 -140 in·lb OEM - Self-extinguishing Time max. 5 s FAR 25.853 12s vertical burn Smoke Density 160 Ds FAR 25 Appendix F at 4 minutes Decomposition by Products - - ABD0031 / AITM 3-0005 Hydrogen Cyanide: max. 5 Decomposition by Products - - ABD0031 / AITM 3-0005 Carbon Monoxide: 200 Decomposition by Products - - ABD0031 / AITM 3-0005 Nitrogen Oxides: 60 Decomposition by Products - - ABD0031 / AITM 3-0005 Sulfur Dioxide: 8 Decomposition by Products - - ABD0031 / AITM 3-0005 Hydrogen Fluoride: max. 5 Decomposition by Products - - ABD0031 / AITM 3-0005 Hydrogen Chloride: max. 5 - Curing Cycle

Property Value Unit Condition Gel Time 18 min at 77°F (25°C), 60g Typical Cure Cycles - - 3 days at 77°F (25°C) or Gel at 77°F (25°C) + minimum of 5 hours at 125°F (52°C)

Property Value Unit Condition Gel time 18 min at 77°F (25°C), 60g Typical cure cycles 3 days days at 77°F (25°C) or Gel at 77°F (25°C) + minimum of 5 hours at 125°F (52°C)

- Curing Cycle

Property Value Unit Test Method Condition Gel time 18 min - at 77°F (25°C), 60g Typical cure cycles 3 days days - at 77°F (25°C) or Gel at 77°F (25°C) + minimum of 5 hours at 125°F (52°C)

- Mix Ratio Tolerance

While the above chart shows that small mix ratio deviations occurring during the processing of EPOCAST® 1648 A/B will have a minimal impact on the system performance properties, the system will only perform optimally when used at the recommended mix ratio.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Storage Conditions

- EPOCAST® 1648 A/B should be stored in a dry place, in the sealed original container, at temperatures between +2°C and +40°C (+35.6°F and 104°F). EPOCAST® 1648 A/B should not be exposed to direct sunlight. Under these storage conditions, and when supplied under Huntsman standard certification, this product has a shelf life of 6 months from the date of shipment from Huntsman or ASN (Authorized Service Network) distributor.

- Material temperatures should be above 18°C (65°F) when mixing. Unused mixed material should be stored in tightly sealed containers.

- Storage Information

- Epocast® 1648 A/B should be stored in a dry place, in the sealed original container, at temperatures between +2°C and +40°C (+35.6°F and 104°F).

- The product should not be exposed to direct sunlight.

- Under these storage conditions, and when supplied under Huntsman standard certification, this product has a shelf life of 6 months from the date of shipment from Huntsman or ASN (Authorized Service Network) distributor.

- Material temperatures should be above 18°C (65°F) when mixing.

- Unused mixed material should be stored in tightly sealed containers.

Other

- Appearance

- Off white paste

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.2 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Density 0.65-0.7 g/cm³ g/cm³ ASTM D1875 Gel Time 18.0 m m ASTM D2471 at 25°C, 60g