Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Features

- Room temperature curing

- Solvent free polyurethane adhesive

- Bonds a wide variety of materials

Applications & Uses

- Compatible Substrates & Surfaces

Properties

- Physical Form

Technical Details & Test Data

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded.Mix Ratio

Parts by Weight

Parts by Volume

Ureol® 1356 A 20 25 Ureol® 1356 B 100 100 Resin and hardener should be blended until they form a homogeneous mix.

Application of adhesive

The resin/hardener mix is applied with a spatula to the pretreated and dry joint surfaces. The joint components should be assembled and clamped as soon as the adhesive has been applied.

Typical curing times

The minimum curing time for light handling will depend on the temperature at which the adhesive is cured. The adhesive is designed to give a safe handling strength after a cure of 24 hours at 20°C. Full strength will be achieved after exposure to temperatures of 20°C during 5 days.

Cure temperatureMinimum Cure Time

Proposed Cure Time

20°C 4 - 5 hours 24 h 40°C 60 min 4 h 60°C 35 min 45 min 80°C 15 min 20 min 100°C 10 min 10 min - Curing Cycle

Typical Cured Properties

Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lap-jointing 170 x 25 x 1.5 mm strips of aluminium alloy.

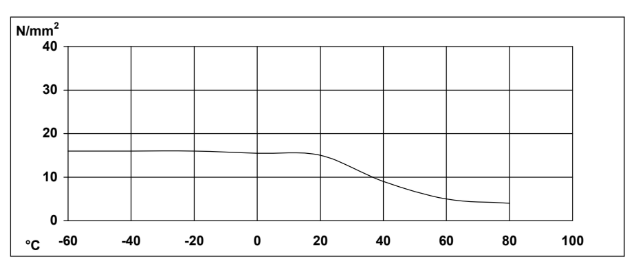

The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification.Lap shear strength variation vs. Temperature

Cure = 4 hours at 40°C + 5 days at 20°C

Lap shear strength variation vs. Temperature and TimeCondition Curing Time Lap Shear Strength (N/mm²)

20°C

5 hours 2 - 3 24 hours 6 - 8 5 days 14 - 16 40°C

1 hour 7 - 8 4 hours 9 - 11 60°C

38 min 8 - 10 1 hour 12 - 13 80°C

20 min 10 - 11 1 hour 13 - 14 100°C

10 min 10 - 11 30 min 12 - 14 Roller peel test

4-6 kp/cm

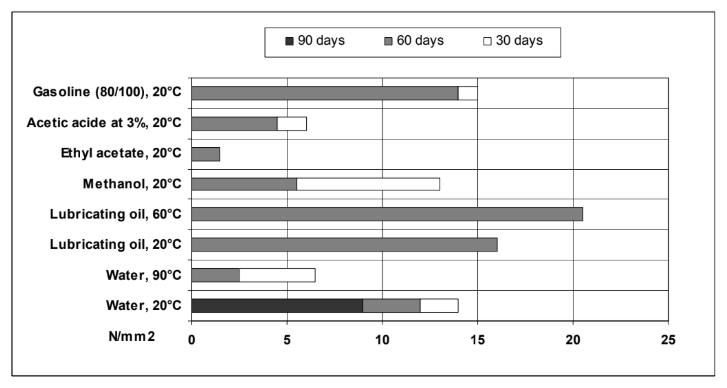

Lap shear strength versus immersion in various media (typical average values)

Cure = 4 hours at 40°C + 5 days at 20°C

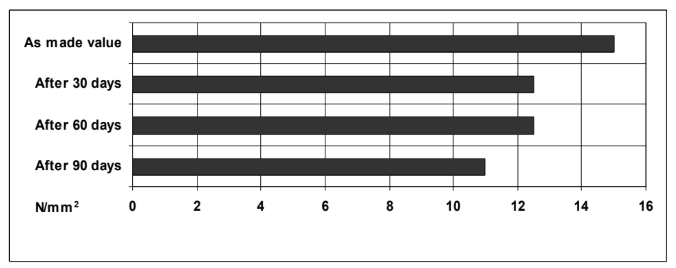

Lap shear strength versus tropical weathering (40/92, DIN 50015 ; typical average values)Cure = 4 hours at 40°C + 5 days at 20°C

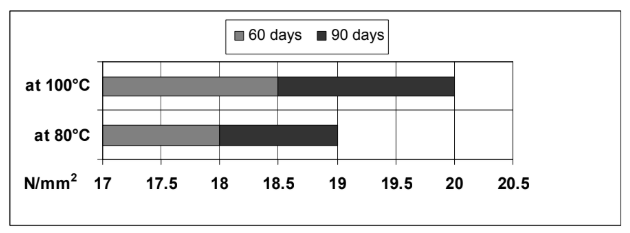

Lap shear strength versus heat ageingCure = 4 hours at 40°C + 5 days at 20°C

Safety & Health

- Handling Precaution

Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin

should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Storage & Handling

- Storage Conditions

Ureol® 1356 A and Ureol® 1356 B may be stored at 18-20°C provided the components are stored in sealed containers. The expiry date is indicated on the label. Keep contenairs in dry atmosphere, avoid to exposure the containers to the moisture and direct sources of heat.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.2 %(W) Hardener : Resin